Kaviri-Sid Circuit Boards Prototype Pcb Mugadziri

PCB Process Kugona

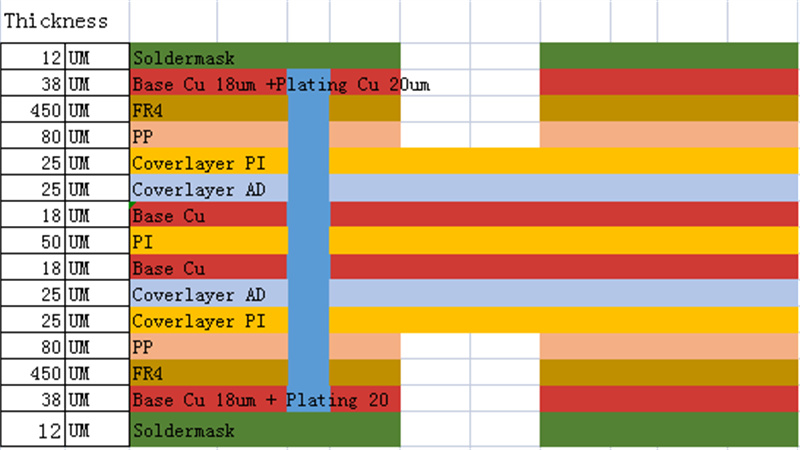

| Aihwa. | Project | Technical zviratidzo |

| 1 | Layer | 1-60 (mutsetse) |

| 2 | Maximum processing area | 545 x 622 mm |

| 3 | Minimumboard thickness | 4(layer)0.40mm |

| 6(layer) 0.60mm | ||

| 8(mutsetse) 0.8mm | ||

| 10(layer)1.0mm | ||

| 4 | Minimum line width | 0.0762mm |

| 5 | Minimum spacing | 0.0762mm |

| 6 | Minimum mechanical aperture | 0.15mm |

| 7 | Gomba rusvingo rwemhangura ukobvu | 0.015mm |

| 8 | Metallized aperture tolerance | ± 0.05mm |

| 9 | Non-metallized aperture kushivirira | ± 0.025mm |

| 10 | Gomba kushivirira | ± 0.05mm |

| 11 | Dimensional kushivirira | ± 0.076mm |

| 12 | Minimum solder zambuko | 0.08mm |

| 13 | Insulation resistance | 1E+12Ω (yakajairika) |

| 14 | Plate ukobvu ratio | 1:10 |

| 15 | Thermal shock | 288 ℃ (4 nguva mumasekonzi gumi) |

| 16 | Yakakanganiswa uye yakakotama | ≤0.7% |

| 17 | Anti-magetsi simba | >1.3KV/mm |

| 18 | Anti-kubvisa simba | 1.4N/mm |

| 19 | Solder ramba kuoma | ≥6H |

| 20 | Flame retadancy | 94V-0 |

| 21 | Impedance control | ±5% |

Isu tinoita Circuit Boards Prototyping ine makore gumi nemashanu ruzivo nehunyanzvi hwedu

4 layer Flex-Rigid Boards

8 layer Rigid-Flex PCBs

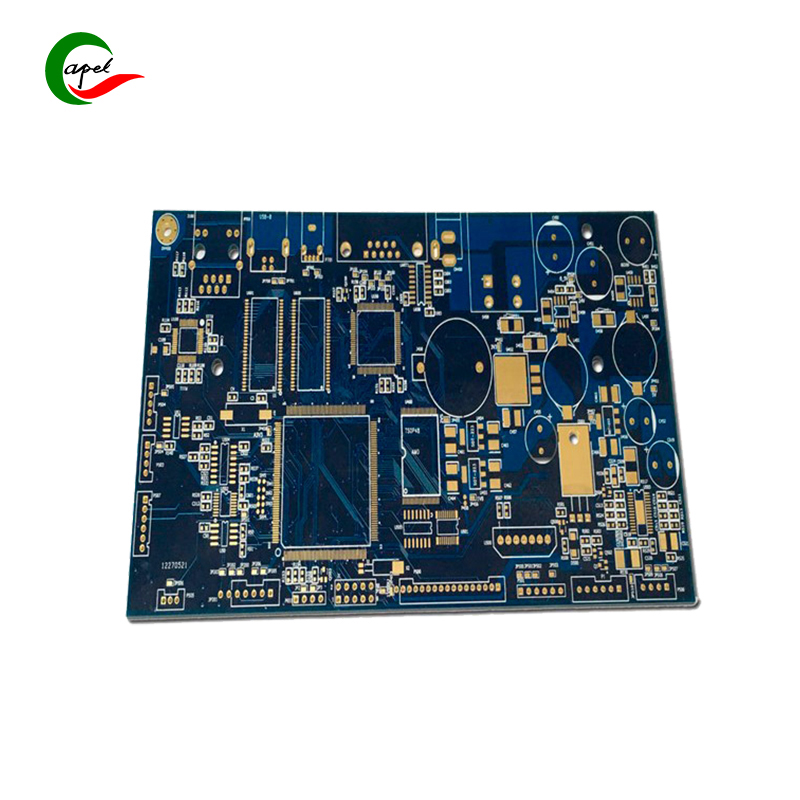

8 layer HDI Yakadhindwa Circuit Boards

Kuedza uye Kuongorora Equipment

Microscope Testing

Kuongorora kweAOI

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Yedu Circuit Boards Prototyping Service

. Ipa rubatsiro rwehunyanzvi Pre-kutengesa uye mushure-kutengesa;

. Tsika anosvika makumi mana akaturikidzana, 1-2days Kurumidza kutendeuka yakavimbika prototyping, Component procurement, SMT Assembly;

. Inobata kune ese ari maviri Medical Device, Industrial Control, Automotive, Aviation, Consumer Electronics, IOT, UAV, Communications etc..

. Zvikwata zvedu zvemainjiniya nevatsvaguri vakazvipira kuzadzisa zvaunoda nehungwaru uye nehunyanzvi.

Maitiro ekugadzira emhando yepamusoro-Maviri-Sided Circuit Boards?

1. Gadzira bhodhi: Shandisa purogiramu yekombiyuta-inobatsirwa (CAD) kugadzira bhodhi. Ita shuwa kuti dhizaini inosangana nezvose zvinodiwa zvemagetsi uye zvemuchina, kusanganisira hupamhi hwekutsvaga, nzvimbo, uye kuiswa kwechikamu. Funga zvinhu zvakadai sechiratidzo chekuvimbika, kugovera simba, uye kutonga kwekushisa.

2. Prototyping uye kuyedza: Pamberi pekugadzirwa kwakawanda, zvakakosha kugadzira prototype board kuti isimbise dhizaini nekugadzira maitiro. Nyatsoyedza prototypes ekushanda, kushanda kwemagetsi, uye kuenderana kwemuchina kuona chero zvingangoitika kana kuvandudzwa.

3. Kusarudzwa Kwezvinhu: Sarudza zvinhu zvemhando yepamusoro zvinoenderana nezvinodiwa zvebhodhi rako. Sarudzo dzezvinhu zvakajairika dzinosanganisira FR-4 kana yakakwirira-tembiricha FR-4 yeiyo substrate, mhangura yekuteedzera trace, uye solder mask kuchengetedza zvikamu.

4. Gadzira iyo yemukati layer: Kutanga gadzira iyo yemukati layer yebhodhi, iyo inosanganisira akati wandei matanho:

a. Chenesa uye roughen mhangura clad laminate.

b. Isa yakaonda photosensitive yakaoma firimu kune mhangura pamusoro.

c. Iyo firimu inoratidzwa kune ultraviolet (UV) mwenje kuburikidza nepikicha chishandiso chine inodiwa yedunhu pateni.

d. Iyo firimu inogadzirwa kuti ibvise nzvimbo dzisina kuvharwa, ichisiya chimiro chedunhu.

e. Etch yakafumurwa mhangura kuti ubvise zvinhu zvakawandisa uchisiya chete zvinodikanwa nemapads.

F. Ongorora mupendero wemukati kuona chero kukanganisa kana kutsauka kubva pakugadzira.

5. Laminates: Inner layers inounganidzwa ne prepreg muchina. Kupisa uye kudzvinyirira kunoshandiswa kusungira zvidimbu uye kuumba pani yakasimba. Ita shuwa kuti matinji emukati akanyatsoenderana uye akanyoreswa kudzivirira chero kusarongeka.

6. Kuchera: Shandisa muchina wekuchera wakanyatso kuchera makomba ekuisa chikamu uye kubatanidza. Saizi dzakasiyana dzezviboorero zvimedu zvinoshandiswa zvinoenderana nezvinodiwa chaizvo. Iva nechokwadi chechokwadi chenzvimbo yegomba uye dhayamita.

Maitiro ekugadzira emhando yepamusoro-Maviri-Sided Circuit Boards?

7. Electroless Copper Plating: Isa chidimbu chitete chemhangura kune zvese zviri pachena zvemukati. Iyi nhanho inovimbisa kwakaringana conductivity uye inofambisa iyo plating maitiro mumatanho anotevera.

8. Outer layer imaging: Yakafanana neyomukati dhizaini dhizaini, photosensitive yakaoma firimu yakaputirwa paganda rekunze remhangura.

Ratidza kune UV mwenje kuburikidza nepamusoro pikicha chishandiso uye gadzira iyo firimu kuratidza redunhu pateni.

9. Outer layer etching: Bvisa mhangura isingakoshi pachikamu chekunze, uchisiya maronda anodiwa uye mapedhi.

Tarisa kunze kwekunze kune chero kukanganisa kana kutsauka.

10. Solder Mask uye Legend Printing: Isa solder mask zvinhu kudzivirira trace copper uye mapedhi paunenge uchisiya nzvimbo yekuiswa chikamu. Dhinda ngano uye mamakisi kumusoro nepasi pasi kuratidza nzvimbo yechikamu, polarity, uye rumwe ruzivo.

11. Kugadzirira Kwepamusoro: Kugadzirira kwepamusoro kunoshandiswa kuchengetedza nzvimbo yakasvibiswa yemhangura kubva kune oxidation uye kupa nzvimbo inotengeswa. Sarudzo dzinosanganisira kupisa kwemhepo kuyera (HASL), electroless nickel kunyudzwa goridhe (ENIG), kana mamwe mapeji epamberi.

.

Iva nechokwadi chokuti mipendero yakachena uye zviyero zvakarurama.

13. Kuedza kweMagetsi: Ita magetsi ekuedza sekuenderera mberi kwekuedza, kuyerwa kwekudzivirira, uye kuongorora kwekuzviparadzanisa kuti uone kushanda uye kuvimbika kwemapuranga akagadzirwa.

14. Kudzora Kwehutano uye Kuongorora: Mabhodhi akapedzwa anonyatsoongororwa kune chero kukanganisa kwekugadzira zvakadai sepfupi, kuvhura, kukanganisa, kana kukanganisa kwepamusoro. Shandisa maitiro ekutonga kwemhando kuti uve nechokwadi chekutevedzera makodhi uye zviyero.

15. Kuisa uye Kutumira: Mushure mokunge bhodhi ichipfuura kuongororwa kwehutano, inotakurwa zvakachengeteka kudzivirira kukanganisa panguva yekutumira.

Ita shuwa kunyorwa kwakaringana uye zvinyorwa kuti unyatso kuronda uye kuona mabhodhi.