Zvemagetsi zvemagetsi zvakadhindwa mabhodhi edunhu (PCBs) anoita basa rakakosha mukushanda kwemotokari dzanhasi dzepamusoro. Kubva pakudzora injini masisitimu uye infotainment zviratidziro kusvika pakutarisira kuchengetedza maficha uye kuzvitonga kutyaira, maPCB aya anoda kungwarira dhizaini uye magadzirirwo ekugadzira kuti ave nechokwadi chekushanda kwakakwana uye kuvimbika.Muchinyorwa chino, tichapinda murwendo rwakaoma rwemotokari dzemagetsi PCBs, tichiongorora matanho akakosha anosanganisirwa kubva padanho rekutanga rekugadzira kusvika pakugadzira.

1.Kunzwisisa mota dzemagetsi PCB:

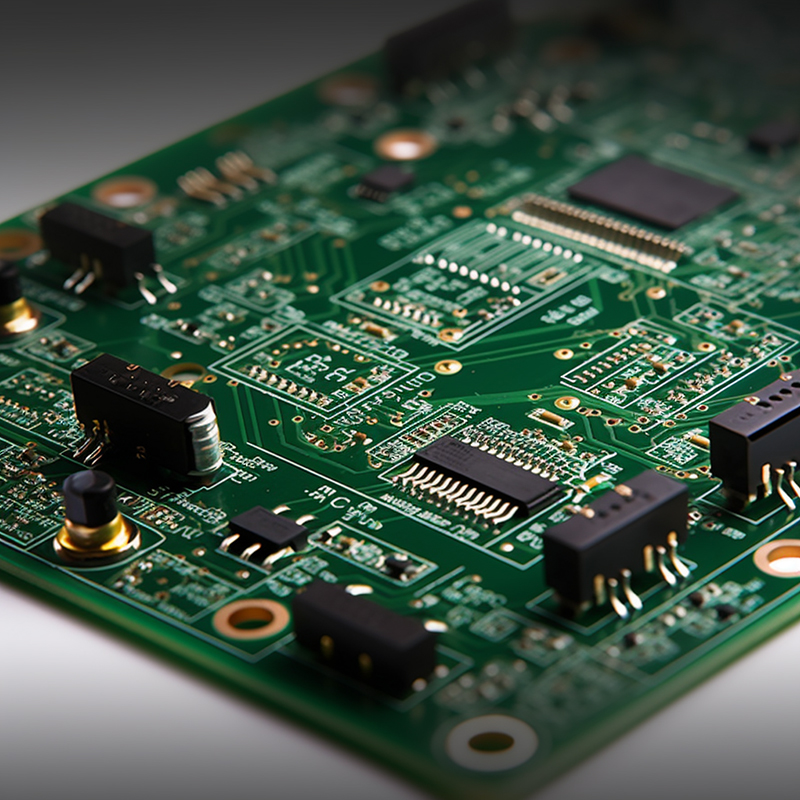

Zvemotokari zvemagetsi PCB kana kudhindwa redunhu bhodhi chikamu chakakosha chemotokari dzemazuva ano. Ivo vane basa rekupa kubatanidza magetsi nerutsigiro rweakasiyana emagetsi masisitimu mumotokari, senge injini yekudzora mayunitsi, infotainment masisitimu, masensa, etc.Chinhu chakakosha chemagetsi emotokari PCBs kugona kwavo kutsungirira hutsinye hwemotokari nharaunda. Mota dziri pasi pekuchinja kwakanyanya kwekushisa, kuzunguzika uye ruzha rwemagetsi. Naizvozvo, maPCB aya anofanirwa kuve akasimba uye akavimbika kuti ave nechokwadi chekuita kwakanaka uye kuchengetedzeka. Zvemotokari zvemagetsi maPCB anowanzo kugadzirwa achishandisa nyanzvi software inobvumira mainjiniya kugadzira marongero anosangana nezvinodiwa chaizvo zveindasitiri yemotokari. Izvi zvinodikanwa zvinosanganisira zvinhu zvakaita sehukuru, huremu, mashandisiro emagetsi, uye kuenderana kwemagetsi nezvimwe zvinhu. Iyo nzira yekugadzira yemotokari yemagetsi PCBs inosanganisira akawanda matanho. Iyo PCB dhizaini yakagadzirwa kutanga uye yakanyatso edzerwa uye yakaedzwa kuti ive nechokwadi chekuti dhizaini inosangana nezvinodiwa. Iyo dhizaini inozoendeswa kune yemuviri PCB uchishandisa matekiniki akadai sekuisa kana kuisa conductive zvinhu paPCB substrate. Tichifunga kuomarara kwemotokari dzemagetsi PCBs, zvimwe zvinhu zvakaita seresistors, capacitors, uye maseketi akasanganiswa anowanzo kuisirwa paPCB kupedzisa dunhu remagetsi. Izvi zvikamu zvinowanzoiswa pamusoro pePCB uchishandisa otomatiki yekuisa michina. Kunyanya kutarisisa kunobhadharwa kune welding process kuti ive nechokwadi chekubatanidza uye kusimba. Tichifunga kukosha kwemotokari dzemagetsi masisitimu, kutonga kwemhando kwakakosha muindasitiri yemotokari. Naizvozvo, mota dzemagetsi PCBs dzinoedzwa zvakasimba uye nekuongororwa kuti dzive nechokwadi chekuti dzinosangana nezvinodiwa. Izvi zvinosanganisira kuyedzwa kwemagetsi, kuchovha bhasikoro, kuyedza vibration uye kuongororwa kwezvakatipoteredza kuti ive nechokwadi chekuvimbika kwePCB uye kusimba pasi pemamiriro akasiyana.

2.Automotive electronic PCB design process:

Iyo mota yemagetsi PCB dhizaini dhizaini inosanganisira akati wandei akakosha matanho ekuona kuvimbika, kushanda, uye kuita kwechigadzirwa chekupedzisira.

2.1 Scheme dhizaini: Nhanho yekutanga mumagadzirirwo ekugadzira ndeye dhizaini dhizaini.Munhanho iyi, mainjiniya anotsanangura kubatanidzwa kwemagetsi pakati pezvikamu zvega zvichibva pane zvinodiwa nePCB. Izvi zvinosanganisira kugadzira dhizaini inomiririra PCB dunhu, kusanganisira zvinongedzo, zvikamu, uye hukama hwavo. Munguva iyi, mainjiniya anotarisa zvinhu zvakaita sezvinodiwa zvesimba, nzira dzechiratidzo, uye kuenderana nemamwe masisitimu mumotokari.

2.2 PCB dhizaini dhizaini: Kana iyo schematic yapera, dhizaini inoenda muPCB dhizaini yekugadzira chikamu.Munhanho iyi, mainjiniya anoshandura schematic kuita chimiro chePCB. Izvi zvinosanganisira kuona hukuru, chimiro, uye nzvimbo yezvikamu pabhodhi redunhu, pamwe chete nekutenderera kwemagetsi emagetsi. Dhizaini yedhizaini inofanirwa kutarisa zvinhu zvakaita sechiratidzo chekuvimbika, kutungamira kwekupisa, kupindira kwemagetsi (EMI), uye kugadzirwa. Kunyanya kutariswa kunobhadharwa kune chikamu chekuisa kuti uwedzere kuyerera kwechiratidzo uye kuderedza ruzha.

2.3 Kusarudzwa kwechikamu uye kuiswa: Mushure mekutanga PCB marongerwo apera, mainjiniya anoenderera mberi nekusarudzwa kwechikamu uye kuiswa.Izvi zvinosanganisira kusarudza zvikamu zvakakodzera zvichienderana nezvinodiwa senge kuita, mashandisirwo emagetsi, kuwanikwa uye mutengo. Zvinhu zvakadai semotokari-giredhi zvikamu, tembiricha yemhando uye vibration kushivirira zvakakosha mukuita sarudzo. Izvo zvikamu zvinozoiswa paPCB zvinoenderana nekwavo tsoka uye zvinzvimbo zvakatemerwa panguva yedhizaini dhizaini. Kuiswa kwakakodzera uye kutaridzika kwezvikamu kwakakosha pakuona kuungana kwakanyatso uye kuyerera kwechiratidzo.

2.4 Chiratidzo chekuvimbika kwekuongorora: Chiratidzo chekuvimbika kuongororwa inhanho yakakosha mumotokari yemagetsi PCB dhizaini.Zvinosanganisira kuongorora kunaka uye kuvimbika kwezviratidzo sezvavanoparadzira kuburikidza nePCB. Ongororo iyi inobatsira kuona zvingangoitika matambudziko akadai sechiratidzo chekudzivirira, crosstalk, kuratidzira, uye kukanganiswa kweruzha. Yakasiyana-siyana yekufananidza uye yekuongorora maturusi anoshandiswa kuonesa dhizaini uye kugadzirisa marongero kuti ive nechokwadi chekuvimbika kwechiratidzo. Vagadziri vanotarisa pazvinhu zvakaita sehurefu hwekutsvagisa, impedance yekufananidza, simba rekuvimbika, uye inodzorwa impedance routing kuti ive nechokwadi chekufambisa uye kusina ruzha.

Signal kutendeseka ongororo zvakare inofunga nezve yakakwirira-kumhanya masaini uye yakakosha mabhazi interfaces aripo mumotokari dzemagetsi masisitimu. Sezvo matekinoroji epamberi akadai seEthernet, CAN uye FlexRay ari kuwedzera kushandiswa mumotokari, kuchengetedza kutendeseka kwechiratidzo kunowedzera kunetsa uye kwakakosha.

3.Automotive electronic PCB kugadzira maitiro:

3.1 Kusarudzwa kwezvinhu: Zvemotokari zvemagetsi PCB kusarudzwa kwezvinhu zvakakosha pakuona kusimba, kuvimbika uye kuita.Zvishandiso zvinoshandiswa zvinofanirwa kumirisana neyakaomarara mamiriro ezvakatipoteredza anowanikwa mumashandisi emotokari, kusanganisira shanduko yetembiricha, vibration, mwando uye kuratidzwa kwemakemikari. Zvishandiso zvinowanzoshandiswa zvemotokari zvemagetsi PCBs zvinosanganisira FR-4 (Flame Retardant-4) epoxy-based laminate, ine magetsi akanaka ekudzivirira, simba remagetsi uye yakanakisa kupisa kupisa. High-temperature laminates senge polyimide anoshandiswawo mumaapplication anoda yakanyanya tembiricha kuchinjika. Kusarudzwa kwezvinhu kunofanirawo kufunga nezvezvinodiwa zvedunhu rekushandisa, senge masaini ekumhanya-mhanya kana magetsi emagetsi.

3.2 PCB yekugadzira tekinoroji: PCB yekugadzira tekinoroji inosanganisira akawanda maitiro anoshandura madhizaini kuita mabhodhi edunhu akadhindwa.Nzira yekugadzira inowanzobatanidza matanho anotevera:

a) Dhizaini Dhizaini:Iyo PCB dhizaini inoendeswa kune yakatsaurirwa software inogadzira iyo artwork mafaera anodiwa pakugadzira.

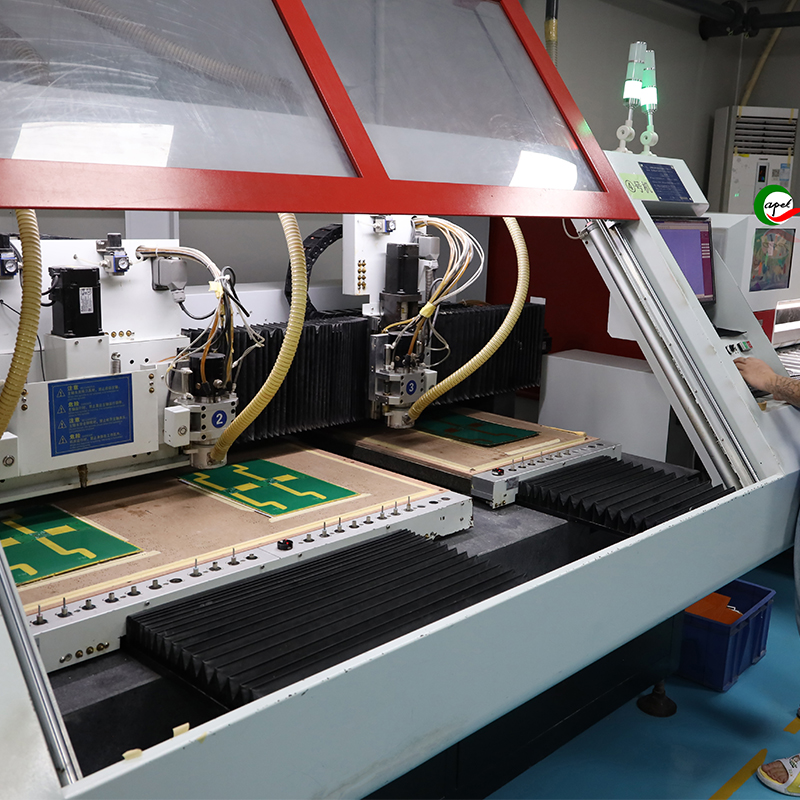

b) Panelization:Kubatanidza akawanda PCB dhizaini mune imwe mapaneru kukwirisa kugadzira kugadzira.

c) Mufananidzo:Pfekedza dhizaini yephotosensitive zvinhu papaneri, uye shandisa iyo artwork faira kufumura inodiwa yedunhu pateni pane yakavharidzirwa.

d) Etching:Kemikari etching nzvimbo dzakavhurika dzepaneru kuti ibvise mhangura isingadikanwi, ichisiya inodiwa yedunhu.

e) Kuchera:Kuchera maburi mupaneru kuti igare chikamu chinotungamira uye vias yekubatanidza pakati pezvikamu zvakasiyana zvePCB.

f) Electroplating:Iro rakatetepa remhangura rinoiswa electroplated pane panhizha kuti riwedzere conductivity yedunhu reti uye rinopa rakatsetseka pamusoro pezvinotevera maitiro.

g) Solder Mask Application:Isa dhizaini yemasolder mask kuchengetedza mhangura kubva kune oxidation uye nekupa insulation pakati pematanho ari padyo. Solder mask inobatsirawo kupa mutsauko wakajeka wekuona pakati pezvikamu zvakasiyana uye zviteshi.

h) Kudhinda skrini:Shandisa iyo skrini yekudhinda maitiro kudhinda mazita echikamu, marogo uye rumwe ruzivo rwakakosha paPCB.

3.3 Gadzirira dhizaini yemhangura: Usati wagadzira dunhu rekushandisa, zvidimbu zvemhangura paPCB zvinoda kugadzirirwa.Izvi zvinosanganisira kuchenesa nzvimbo yemhangura kubvisa chero tsvina, oxides kana zvinosvibisa. Iyo yekuchenesa maitiro inonatsiridza kunamatira kwe photosensitive zvinhu zvinoshandiswa mukufungidzira maitiro. Nzira dzakasiyana-siyana dzekuchenesa dzinogona kushandiswa, kusanganisira kukwesha kwemuchina, kuchenesa makemikari, uye kuchenesa plasma.

3.4 Dunhu rekushandisa: Kana mhangura dzemhangura dzagadzirwa, dunhu rekushandisa rinogona kugadzirwa paPCB.Izvi zvinosanganisira kushandisa nzira yekufungidzira kuendesa yaunoda sedunhu paPCB. Iyo artwork faira inogadzirwa nePCB dhizaini inoshandiswa sereferensi yekufumura iyo photosensitive zvinhu paPCB kune UV mwenje. Iyi nzira inoomesa nzvimbo dzakafumurwa, dzichigadzira inodiwa yedunhu traces uye mapedhi.

3.5 PCB etching uye kuchera: Mushure mekugadzira dunhu rekushandisa, shandisa kemikari mhinduro kudzima mhangura yakawandisa.Iyo photosensitive zvinhu inoshanda semasiki, inodzivirira inodiwa yedunhu reti kubva pakucheka. Tevere kunouya iyo yekuchera maitiro ekugadzira makomba echikamu chinotungamira uye vias muPCB. Maburi anocherwa pachishandiswa maturusi chaiwo uye nzvimbo dzawo dzinotemerwa zvichienderana nePCB dhizaini.

3.6 Kuisa uye solder mask application: Mushure mekunge etching uye kudhirowa kwapera, PCB inoputirwa kuti iwedzere kufambiswa kwemaitiro edunhu.Gadzira chidimbu chitete chemhangura panzvimbo yemhangura iri pachena. Iyi plating maitiro inobatsira kuve nechokwadi chekubatanidza magetsi uye inowedzera PCB kusimba. Mushure mekuputira, chigadziko che solder mask chinoiswa kuPCB. Iyo solder mask inopa insulation uye inodzivirira mitsetse yemhangura kubva kune oxidation. Inowanzo shandiswa nekudhindwa kwechidzitiro, uye nzvimbo inoiswa zvikamu inosiiwa yakavhurika kuti ishandiswe.

3.7 PCB kuyedzwa uye kuongorora: Nhanho yekupedzisira mukugadzira maitiro ndeye PCB yekuongorora uye kuongorora.Izvi zvinosanganisira kutarisa kushanda uye kunaka kwePCB. Miedzo yakasiyana-siyana senge kuenderera mberi kuyedza, kuyedza kudzivirira, uye kuongororwa kwemagetsi kunoitwa kuti ive nechokwadi chekuti PCB inosangana nezvinodiwa. Ongororo yekuona inoitwawo kutarisa chero chakakanganisika senge short, kuvhura, misalignments, kana component placement defects.

Iyo mota yemagetsi PCB yekugadzira maitiro inosanganisira akatevedzana matanho kubva pakusarudzwa kwezvinhu kusvika pakuyedzwa uye kuongorora. Nhanho imwe neimwe inoita basa rakakosha mukuona kuvimbika, kushanda uye kuita kwePCB yekupedzisira. Vagadziri vanofanirwa kuomerera kune indasitiri zviyero uye akanakisa maitiro ekuona kuti maPCB anosangana nezvinodiwa zvakaomesesa zvekushandisa kwemotokari.

4.Car-zvakananga kufunga: kune zvimwe zvemotokari-zvakananga zvinhu zvinofanirwa kutariswa pakugadzira uye.

kugadzira mota dzePCBs.

4.1 Kupisa kupisa uye kutonga kwekupisa: Mumotokari, maPCB anokanganiswa nepamusoro tembiricha mamiriro nekuda kwekupisa kweinjini uye nharaunda yakatenderedza.Naizvozvo, kupisa kupisa uye kutonga kwekupisa ndizvo zvakakosha kufunga mumotokari PCB dhizaini. Zvinhu zvinogadzira kupisa zvakaita semagetsi emagetsi, mamicrocontrollers, uye masensa zvinofanirwa kuiswa zvine hungwaru paPCB kuderedza kupisa. Heat sinks uye mavhavha anowanikwa kuti akwanise kupisa kupisa. Pamusoro pezvo, mafambiro emhepo akakodzera uye nzira dzekutonhodza dzinofanirwa kuiswa mumagadzirirwo emotokari kudzivirira kuwanda kwekupisa uye kuve nechokwadi chekuvimbika kwePCB uye hupenyu hurefu.

4.2 Vibration uye kushomeka kuramba: Motokari dzinoshanda pasi pemamiriro akasiyana-siyana emigwagwa uye dziri pasi pekudengenyeka uye kushamiswa kunokonzerwa nemapumbu, makomba uye nzvimbo yakaoma.Aya mavibrations uye kuvhunduka anogona kukanganisa PCB kusimba uye kuvimbika. Kuve nechokwadi chekuramba kuzunguzika uye kuvhunduka, maPCB anoshandiswa mumotokari anofanirwa kuve akasimba uye akaiswa zvakachengeteka. Madhizaini ekugadzira akadai sekushandisa ekuwedzera majoini ekutengesa, kusimbisa iyo PCB ne epoxy kana yekusimbisa zvinhu, uye nekungwarira kusarudza vibration-inodzivirira zvikamu uye zvinobatanidza zvinogona kubatsira kudzikisira mhedzisiro yakaipa yekuzunguza uye kuvhunduka.

4.3 Electromagnetic kuenderana (EMC): Electromagnetic interference (EMI) uye redhiyo frequency interference (RFI) inogona kukanganisa mashandiro emagetsi emotokari.Kubatana kwepedyo kwezvinhu zvakasiyana-siyana mumotokari kunoburitsa minda yemagetsi inovhiringidza mumwe nemumwe. Kuti ive nechokwadi cheEMC, PCB dhizaini inofanirwa kusanganisa yakakodzera kudzivirira, kumisa pasi, uye kusefa matekiniki ekudzikisa kuburitsa uye kubatwa nemagetsi masaini. Shielding cans, conductive spacers, uye akakodzera PCB marongerwo matekiniki (sekuparadzanisa anonzwa analog uye madhijitari traces) anogona kubatsira kuderedza mhedzisiro yeEMI neRFI uye kuve nechokwadi chekushanda kwakakodzera kwemagetsi emotokari.

4.4 Kuchengetedza uye kuvimbika zviyero: Zvemagetsi zvemotokari zvinofanirwa kutevedzera kuchengetedzeka kwakasimba uye kuvimbika zviyero kuti ive nechokwadi chekuchengetedzwa kwevafambi uye kushanda kwese kwemotokari.Aya mazinga anosanganisira ISO 26262 yekuchengetedzwa kwekushanda, inotsanangura zvinodiwa zvekuchengetedza mota dzemumugwagwa, uye dzakasiyana siyana dzenyika uye dzepasirese zviyero zvekuchengetedzwa kwemagetsi uye kufunga kwezvakatipoteredza (seIEC 60068 yekuongororwa kwezvakatipoteredza). Vagadziri vePCB vanofanirwa kunzwisisa uye kutevedzera zviyero izvi pakugadzira nekugadzira mota dzePCB. Pamusoro pezvo, kuyedza kuvimbika senge tembiricha bhasikoro, kuyedza vibration, uye kukurumidza kuchembera kunofanirwa kuitwa kuti ive nechokwadi chekuti PCB inosangana nemazinga ekuvimbika anodiwa ekushandisa mota.

Nekuda kweiyo tembiricha yepamusoro yenzvimbo yemotokari, kupisa kupisa uye kutonga kwekupisa kwakakosha. Vibration uye kushomeka kuramba kwakakosha kuve nechokwadi kuti PCB inogona kumira nemamiriro emumugwagwa akaomarara. Electromagnetic kuenderana kwakakosha kudzikisa kupindirana pakati peakasiyana emagetsi emagetsi emagetsi. Pamusoro pezvo, kutevedzera kuchengetedzwa uye kuvimbika zviyero zvakakosha kuti uve nechokwadi chekuchengetedza uye kushanda zvakanaka kwemotokari yako. Nekugadzirisa matambudziko aya, vagadziri vePCB vanogona kugadzira maPCB emhando yepamusoro anosangana nezvinodiwa zveindasitiri yemotokari.

5.Automotive electronic PCB gungano uye kubatanidzwa:

Zvemotokari zvemagetsi PCB kuungana uye kubatanidzwa kunosanganisira matanho akasiyana siyana anosanganisira kutenga chikamu, pamusoro pekukwira tekinoroji musangano, otomatiki uye manyorerwo nzira dzekugadzira, uye kutonga kwemhando uye kuyedzwa. Imwe neimwe nhanho inobatsira kuburitsa emhando yepamusoro, yakavimbika maPCB inosangana nezvinodiwa zvakaomesesa zvemotokari application. Vagadziri vanofanirwa kutevedzera maitiro akasimba uye zviyero zvemhando yekuona kuita uye hupenyu hurefu hweizvi zvikamu zvemagetsi mumotokari.

5.1 Kutenga kwechikamu: Kutenga kwezvikamu inhanho yakakosha mumotokari yemagetsi PCB gungano maitiro.Chikwata chekutenga chinoshanda padhuze nevatengesi kuti vatore uye vatenge zvinodikanwa. Zvikamu zvakasarudzwa zvinofanirwa kusangana nezvinodiwa zvekushanda, kuvimbika, uye kuenderana nemotokari application. Maitiro ekutenga anosanganisira kuona vatengesi vanovimbika, kuenzanisa mitengo uye nguva dzekutumira, uye kuona kuti zvikamu ndezvechokwadi uye zvinosangana nezvinodiwa zvemhando. Zvikwata zvekutenga zvinofungawo zvinhu zvakaita seobsolescence manejimendi kuti ive nechokwadi chekuwanikwa kwechikamu mukati mehupenyu hwechigadzirwa.

5.2 Surface Mount Technology (SMT): Surface Mount tekinoroji (SMT) ndiyo nzira inosarudzika yekuunganidza mota dzemagetsi PCB nekuda kwekushanda kwayo, kurongeka, uye kuenderana nezvikamu zviduku. SMT inosanganisira kuisa zvikamu zvakananga paPCB pamusoro, kubvisa kudiwa kwemitungamiri kana mapini.Zvikamu zveSMT zvinosanganisira zvidiki, zvisingaremi midziyo senge resistors, capacitors, akasanganiswa maseketi, uye microcontrollers. Izvi zvikamu zvinoiswa paPCB uchishandisa otomatiki yekuisa muchina. Muchina uyu unonyatso misa zvikamu pane solder paste paPCB, kuve nechokwadi kurongeka chaiko uye kuderedza mukana wekukanganisa. Iyo SMT maitiro inopa akati wandei mabhenefiti, anosanganisira yakawedzera chikamu density, yakagadziridzwa kugadzirwa kwekuita, uye kuwedzeredzwa kushanda kwemagetsi. Uye zvakare, SMT inogonesa otomatiki kuongorora uye kuyedza, ichigonesa kukurumidza uye yakavimbika kugadzirwa.

5.3 Otomatiki uye yemanyorero gungano: Gungano remotokari dzemagetsi maPCB anogona kuitwa neotomatiki uye nemanyorero nzira, zvichienderana nekuoma kwebhodhi uye nezvinodiwa chaizvo zvekushandisa.Kuunganidza otomatiki kunosanganisira kushandiswa kwemichina yepamusoro kuunganidza maPCB nekukurumidza uye nemazvo. Otomatiki michina, senge chip mounters, solder paste maprinta, uye reflow oveni, anoshandiswa kuisa chikamu, solder paste application, uye reflow soldering. Automated assembly inoshanda zvakanyanya, inoderedza nguva yekugadzira uye kuderedza zvikanganiso. Manual assembly, kune rumwe rutivi, inowanzoshandiswa pakugadzira yakaderera-vhoriyamu kana kana zvimwe zvikamu zvisina kukodzera kuungana otomatiki. Vanamazvikokota vane hunyanzvi vanoshandisa maturusi ehunyanzvi uye midziyo kunyatsoisa zvikamu paPCB. Kusangana nemaoko kunobvumira kuchinjika kukuru uye kugadzirisa pane kuungana otomatiki, asi inononoka uye inokonzeresa kukanganisa kwevanhu.

5.4 Kudzora Hunhu uye Kuedzwa: Kudzora kwemhando uye kuyedzwa matanho akakosha mumotokari yemagetsi PCB gungano uye kubatanidzwa. Aya maitiro anobatsira kuona kuti chigadzirwa chekupedzisira chinosangana nezvinodiwa zvemhando yepamusoro uye kushanda.Kudzora kwemhando kunotanga nekuongorora zvinhu zvinopinda kuti zvionekwe huchokwadi hwazvo uye mhando. Panguva yegungano, ongororo dzinoitwa pamatanho akasiyana-siyana kuona uye kugadzirisa chero kukanganisa kana nyaya. Visual inspection, automated optical inspection (AOI) uye X-ray inspection inowanzo shandiswa kuona zvikanganiso zvinogona kuitika zvakadai semabhiriji anotengeswa, chikamu chemisalignment kana kuvhurika.

Mushure megungano, iyo PCB inoda kuongororwa inoshanda kuti ione kushanda kwayo. Testing maitiro anogona kusanganisira simba-pakuyedza, mashandiro ekuyedza, in-circuit kuyedzwa, uye kuyedza kwezvakatipoteredza kuti uone kushanda, hunhu hwemagetsi, uye kuvimbika kwePCB.

Kudzora kwemhando uye kuyedzwa kunosanganisirawo kuteedzera, uko PCB yega yega inomakwa kana kucherechedzwa neyakasarudzika identifier yekutevera nhoroondo yayo yekugadzira uye kuve nechokwadi chekuzvidavirira.Izvi zvinoita kuti vagadziri vaone uye vagadzirise chero nyaya uye inopa yakakosha data yekuenderera mberi kuvandudza.

6.Automotive electronic PCB Remangwana maitiro uye matambudziko:Ramangwana remotokari dzemagetsi PCBs richakonzerwa ne

maitiro akadai se miniaturization, kuwedzera kuomarara, kubatanidzwa kwehunyanzvi tekinoroji, uye kudiwa kwekuvandudzwa.

nzira dzekugadzira.

6.1 Miniaturization uye yakawedzera kuomarara: Imwe yeakakosha mafambiro mumotokari yemagetsi PCBs ndiyo inoenderera mberi kusunda kweminiaturization uye kuoma.Sezvo mota dzichiwedzera kufambira mberi uye dzakashongedzerwa akasiyana emagetsi masisitimu, kudiwa kwemadiki uye denser PCBs kuri kuramba kuchiwedzera. Iyi miniaturization inounza matambudziko mukuiswa kwechikamu, nzira, kuparara kwemafuta, uye kuvimbika. Vagadziri vePCB nevagadziri vanofanirwa kuwana mhinduro nyowani dzekugadzirisa kuderera kwemafomu zvinhu uku vachichengetedza PCB kuita uye kusimba.

6.2 Kubatanidzwa kwehunyanzvi hwepamusoro: Indasitiri yemotokari iri kuona kufambira mberi nekukurumidza muhunyanzvi, kusanganisira kubatanidzwa kwehunyanzvi hwepamusoro mumotokari.MaPCB anoita basa rakakosha mukugonesa matekinoroji aya, senge advanced driver assistance system (ADAS), mota dzemagetsi masisitimu, yekubatanidza mhinduro uye inozvimiririra yekutyaira. Aya matekinoroji epamberi anoda maPCB anogona kutsigira kumhanya kwepamusoro, kubata yakaoma data kugadzirisa, uye kuve nechokwadi kutaurirana kwakavimbika pakati pezvikamu zvakasiyana uye masisitimu. Kugadzira nekugadzira maPCB anosangana nezvinodiwa izvi idambudziko rakakura kune indasitiri.

6.3 Maitiro ekugadzira anofanirwa kusimbiswa: Sezvo kudiwa kwePCB yemotokari yemagetsi kuri kuramba kuchikura, vagadziri vakatarisana nedambudziko rekusimudzira maitiro ekugadzira kuti asangane neakakwira mavhoriyamu ekugadzirwa uku vachichengetedza mazinga emhando yepamusoro.Kugadzirisa maitiro ekugadzira, kuvandudza kushanda zvakanaka, kupfupisa kutenderera nguva uye kuderedza hurema inzvimbo dzinofanirwa kutariswa nevagadziri. Kushandiswa kwehunyanzvi hwekugadzira matekinoroji, senge otomatiki kuungana, marobhoti uye epamberi ekuongorora masisitimu, anobatsira kuvandudza mashandiro uye nemazvo maitiro ekugadzira. Kutora Indasitiri 4.0 pfungwa dzakadai seInternet yezvinhu (IoT) uye data analytics inogona kupa ruzivo rwakakosha mukugadzirisa maitiro uye kufungidzira kugadzirisa, nekudaro ichiwedzera chibereko uye kubuda.

7.Inozivikanwa yemotokari yedunhu bhodhi mugadziri:

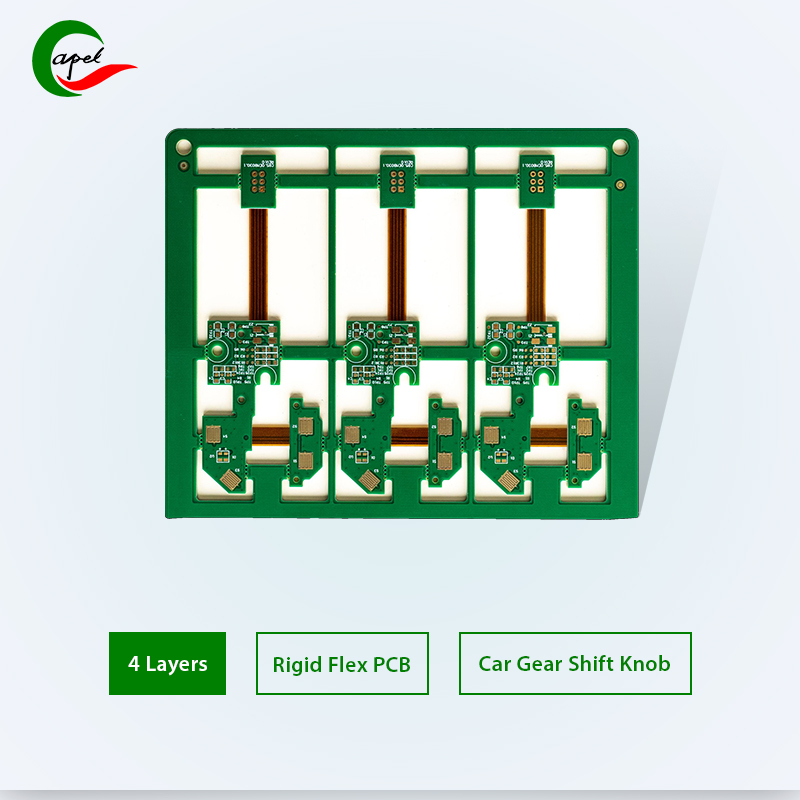

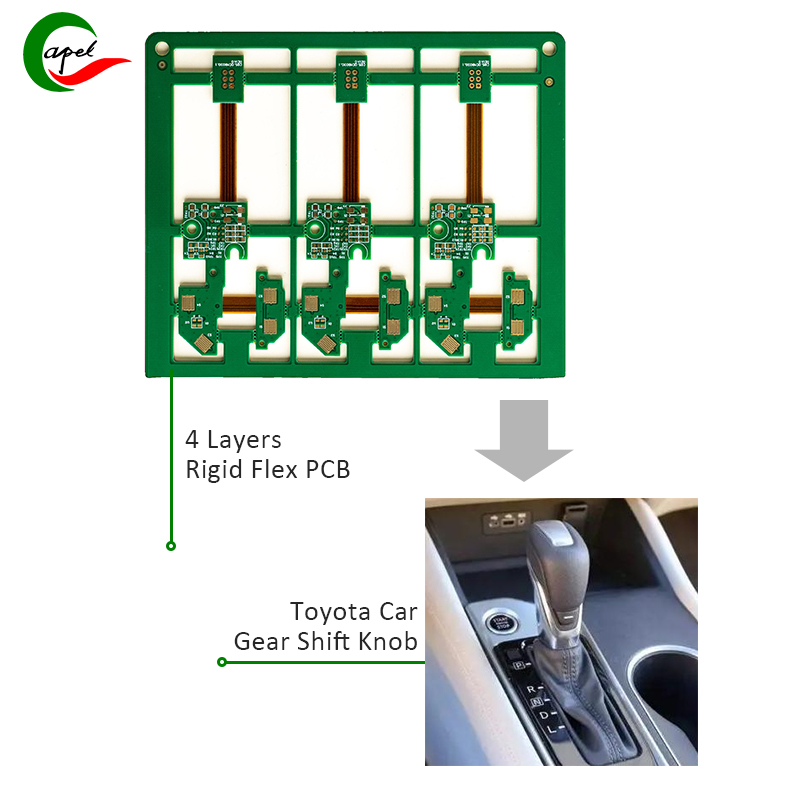

Shenzhen Capel Technology Co., Ltd. yakagadzira fekitori yebhodhi redunhu muna 2009 ndokutanga kugadzira nekugadzira mabhodhi edunhu anochinjika, mabhodhi akasanganiswa, uye mabhodhi akaomarara. Kwemakore gumi nemashanu apfuura, takabudirira kupedza makumi ezviuru zvemotokari yedunhu rebhodhi mapurojekiti evatengi, takaunganidza ruzivo rwakapfuma muindasitiri yemotokari, uye takapa vatengi mhinduro dzakachengeteka uye dzakavimbika. Capel's professional engineering uye R&D zvikwata inyanzvi dzaunogona kuvimba nazvo!

Muchidimbu,iyo mota yemagetsi PCB yekugadzira maitiro ibasa rakaoma uye rine hunyanzvi rinoda kubatana kwepedyo pakati peinjiniya, vagadziri, uye vagadziri. Izvo zvakaomesesa zvinodikanwa zveindasitiri yemotokari zvinoda epamusoro-mhando, akavimbika uye akachengeteka maPCB. Sezvo tekinoroji ichienderera mberi, mota dzemagetsi PCB dzinozoda kusangana nekukura kuri kuita mabasa akaomarara uye akaomarara. Kuti urambe uri pamberi peiyi ndima inokurumidza kubuda, vagadziri vePCB vanofanirwa kufambirana neazvino maitiro. Ivo vanofanirwa kuisa mari mumagadzirirwo epamberi ekugadzira uye michina kuti vave nechokwadi chekugadzirwa kwepamusoro-notch PCBs. Kushandisa maitiro emhando yepamusoro hakungokwidzi ruzivo rwekutyaira chete, asiwo kunoisa pamberi pekuchengetedza uye nemazvo.

Nguva yekutumira: Sep-11-2023

Back