Nhanganyaya

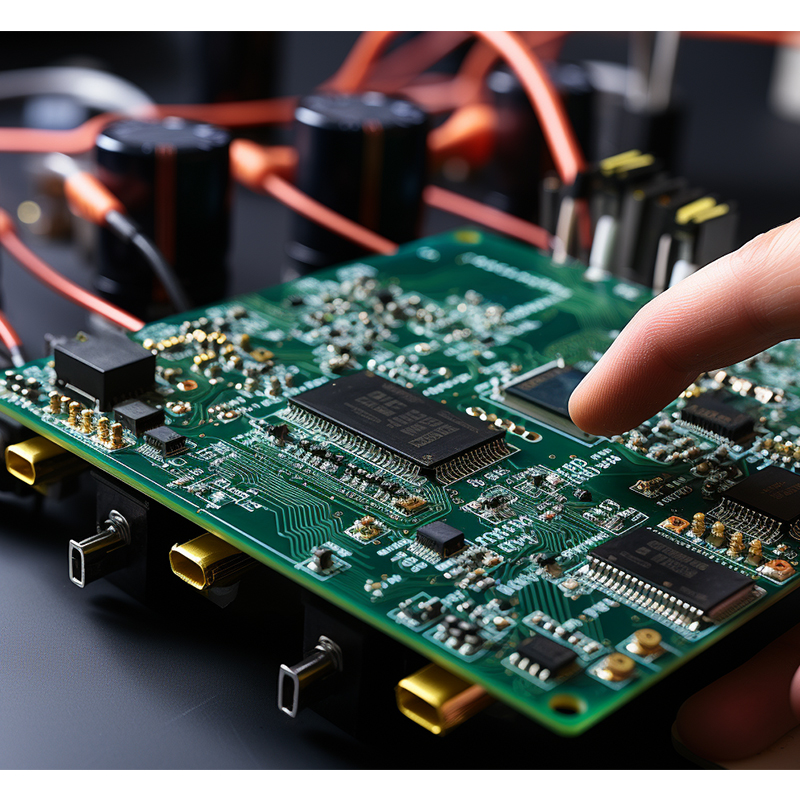

Tikugashirei kune yedu yakazara dhairekitori kumatambudziko akajairika anogona kumuka kana solder redunhu mabhodhi. Soldering inzira yakakosha mukugadzira zvigadzirwa zvemagetsi, uye chero nyaya dzinogona kutungamira kune zvisirizvo kubatana, kutadza kwechikamu, uye kudzikira kwemhando yechigadzirwa.Mune ino blog post, isu tichakurukura nyaya dzakasiyana siyana dzinogona kumuka panguva yedunhu bhodhi soldering, kusanganisira PCB inovhura, chikamu misalignment, soldering nyaya, uye kukanganisa kwevanhu.Isu tichagoverawo matipi ekugadzirisa matambudziko ekukubatsira kukurira matambudziko aya uye kuona yakavimbika soldering panguva yako yemagetsi gungano maitiro.

1. PCB yakavhurika redunhu: zvikonzero uye mhinduro

Imwe yematambudziko akajairika mudunhu bhodhi soldering idunhu rakavhurika, inova isina kukwana kana kushayikwa kubatana pakati pemapoinzi maviri paPCB. Zvikonzero zvikuru zvedambudziko iri zvakaipa solder majoini kana kutyoka conductive traces paPCB. Kuti ugadzirise dambudziko iri, funga zvinotevera mhinduro:

- Tarisa majoini e solder:Nyatsoongorora majoini ega ega ekutengesa kuti uone chero yakasununguka kana isina kukwana. Kana paine zvikanganiso zvakawanikwa, gadzirisazve chibatanidza uchishandisa nzira dzakakodzera dzekutengesa.

- Simbisa PCB dhizaini:Tarisa dhizaini yePCB kune chero nyaya dzine chekuita nedunhu redhisheni, kusakwana kwekutsvaga nzvimbo, kana nzira isiriyo. Rongedza dhizaini kuti usavhure matambudziko edunhu.

- Ita bvunzo yekuenderera mberi:Shandisa multimeter kuona chero discontinuities mumatanho edunhu. Tarisa panzvimbo dzakakanganisika uye gadzirisazve zvibatanidza izvi sezvinodiwa.

2. Component Misalignment: Troubleshooting Guide

Kurongeka kusina kunaka kana kuparadzaniswa kwezvikamu zvinogona kukonzera kukanganisa kwekugadzira uye kutadza kwemagetsi mudziyo. Heano mamwe matipi anoshanda ekugadzirisa nyaya dzemisalignment:

- Ita ongororo yekuona:Ongorora gungano rose rePCB uye simbisa kuiswa uye kurongeka kwechikamu chimwe nechimwe. Tarisa chero zvikamu zvakakotama, zvichibata zvikamu zviri pedyo, kana zvisizvo. Vagadzirise nokungwarira uchishandisa maturusi akakodzera.

- Tarisa zvinotsanangurwa zvechikamu:Tarisa mapepa edatha uye marekisheni echikamu kuti uve nechokwadi chekumisikidza uye kutaridzika panguva yegungano. Kuisa chikamu chisina kunaka chinogona kukonzera nyaya dzekushanda.

- Shandisa jigs uye zvigadziriso:Kushandisa jigs, zvigadziriso uye matemplate zvinogona kuvandudza kurongeka uye kuenderana mukuiswa kwechikamu. Zvishandiso izvi zvinobatsira kurongedza uye kuchengetedza zvikamu munzvimbo chaiyo, kuderedza mukana wekukanganisa.

3. Welding Matambudziko: Troubleshooting Common Defects

Zvinetso zvekutengesa zvinogona kukanganisa zvakanyanya kuita uye kuvimbika kwedunhu bhodhi solder. Ngationgororei mamwe akajairwa soldering kukanganisa uye ane hukama matipi ekugadzirisa matambudziko:

- Yakakanganiswa majoini e solder:Izvi zvinoitika kana iyo soldered yekubatanidza inovhiringidzwa panguva yekutonhora. Kuti udzivise kukanganiswa nejoint ye solder, ita shuwa kuti chikamu nePCB zvinoramba zvakamira mushure mekutengesa kusvikira solder yanyatsotonhodzwa uye yaoma.

- Cold welding:Cold welding spots dzinokonzerwa nekusakwana kupisa panguva yewelding process. Iyo solder inogona kusasunga zvakanaka, zvichikonzera kusabatana kwemagetsi nemagetsi. Shandisa kupisa kwakakwana panguva yekutengesa uye ona kuti solder inoyerera zvakanaka, ichivhara chikamu chinotungamira uye mapedhi.

- Solder bridge:Solder bridging inoitika apo solder yakawandisa inogadzira kubatana kusingatarisirwe pakati pemapini maviri ari padyo kana mapedhi. Nyatsoongorora chibatanidza chimwe nechimwe uye bvisa yakawandisa solder ne desoldering tool kana solder wire. Ita shuwa kuti pane kujeka kwakakodzera pakati pepini nemapadhi kudzivirira bhiriji remangwana.

- Pad kukuvara:Kupisa panguva ye soldering kunogona kukuvadza PCB pads, kukanganisa magetsi. Tora matanho ekudzivirira kudzivirira kuratidzwa kwenguva refu kwemapadhi kune tembiricha yakakwira.

4. Kukanganisa kwevanhu: Kudzivirira Welding Zvikanganiso

Kunyangwe kufambira mberi mune otomatiki, kukanganisa kwevanhu kunoramba kuri chikonzero chakakosha chekuremara kwewelding. Heano mamwe matanho ekuderedza kukanganisa:

- Kudzidziswa uye kuvandudza hunyanzvi:Ita shuwa kuti vashandi vako vakadzidziswa nemazvo uye kusvika parizvino pane zvazvino welding maitiro uye matekiniki. Zvirongwa zvekuvandudza hunyanzvi zvinosimudzira hunyanzvi hwavo uye kuderedza kukanganisa kwevanhu.

- Mashandiro Akajairika (SOPs):Shandisa maSOP chaiwo kune wedunhu bhodhi solder process. Aya maitirwo akamisikidzwa anozobatsira kukwenenzvera mashandiro, kuderedza kusiyanisa, uye kuderedza zvikanganiso.

- Kuongorora Kwekunaka:Batanidza kuomesesa kwemhando yekuongorora yekutarisa mukati mewelding process. Ita ongororo nguva dzose uye gadzirisa matambudziko nekukasira kana awanikwa.

Mhedziso

Circuit board soldering chikamu chakakosha chekugadzirwa kwemagetsi. Nekunzwisisa matambudziko anogona kuitika panguva iyi, unogona kutora matanho ekudzivirira kuti azvidzivirire. Rangarira kutarisa majoini emasoja, kurongedza zvikamu nenzira kwayo, gadzirisa kukanganiswa kwekutengesa nekukasira, uye tora matanho ekudzivirira kukanganisa kwevanhu. Kutevera nhungamiro idzi kuchakubatsira kukunda matambudziko aya uye kuve nechokwadi chekuvimbika uye chemhando yepamusoro-welding process. Happy welding!

Nguva yekutumira: Oct-23-2023

Back