suma:

Mumunda wemagetsi, Akadhindwa Circuit Boards (PCBs) anoita basa rakakosha mukuona kusashanda kwemidziyo yakasiyana siyana. Kuti ive nechokwadi chepamusoro-soro yemhando uye kuvimbika, zvakakosha kuti vagadziri vePCB vashandise matanho ekuongorora akasimba mukati mekuita kwekugadzira.Mune ino blog, isu tichaongorora maitiro ekuongorora emhando anoshandiswa mukambani yedu PCB yekugadzira maitiro, tichitarisa kune edu zvitupa uye patents anoratidza kuzvipira kwedu kune kugona.

Certification uye Accreditations:

Semugadziri wePCB anoremekedzwa, tine zvitupa zvakawanda zvinoratidza kuti tinoomerera kune epamusoro indasitiri zviyero. Kambani yedu yakapfuura ISO 14001:2015, ISO 9001:2015 uye IATF16949:2016 certification. Izvi zvitupa zvinosimbisa kuzvipira kwedu kune manejimendi kwezvakatipoteredza, manejimendi emhando uye mota dzemhando dzekutonga masisitimu zvichiteerana.

Pamusoro pezvo, tinodada kuti takawana UL neROHS Marks, tichienderera mberi nekusimbisa kuzvipira kwedu kutevedzera kuchengetedzwa kwemaitiro uye zvirambidzo pazvinhu zvine njodzi. Kuzivikanwa nehurumende se "chibvumirano chekugara uye chakavimbika" uye "nyika yepamusoro-soro bhizinesi" kunoratidza basa redu uye hunyanzvi muindasitiri.

Innovation patent:

Pakambani yedu, isu tinotenda mukuve pamberi mukufambira mberi kwetekinoroji. Isu takawana huwandu hwegumi nematanhatu emumodhi yemhando patents uye ekutanga patents, kuratidza yedu inoenderera kuedza kuvandudza kunaka uye kushanda kwePCBs. Aya ma patent chiratidzo chehunyanzvi hwedu uye kuzvipira kune hunyanzvi, kuve nechokwadi chekuti maitiro edu ekugadzira akagadziridzwa kuti aite zvakakwana.

Pre-kugadzirwa kwemhando yekuongorora matanho:

Kudzora kwemhando kunotanga pakutanga kwePCB kugadzira maitiro. Kuti tive nechokwadi chepamusoro-soro, isu tinotanga tanyatsoongorora zvakatemwa zvevatengi vedu uye zvinodiwa. Chikwata chedu cheinjiniya chine ruzivo chinonyatsoongorora magwaro ekugadzira uye kutaurirana nevatengi kujekesa chero kusanzwisisika tisati taenda kumberi.

Kana dhizaini yatenderwa, tinonyatso ongorora uye tinosarudza zvemhando yepamusoro zvigadzirwa, zvinosanganisira substrate, foil yemhangura, uye solder mask inki. Zvishandiso zvedu zvinopinda mukuongororwa kwemhando yepamusoro kuti ive nechokwadi chekutevedzera zviyero zveindasitiri seIPC-A-600 uye IPC-4101.

Munguva yepamberi-yekugadzira chikamu, isu tinoitisa dhizaini yekugadzira (DFM) ongororo yekuona chero zvingangoitika zvekugadzira nyaya uye kuona goho rakakwana uye kuvimbika. Iyi nhanho zvakare inotitendera kuti tipe mhinduro dzakakosha kune vatengi vedu, kukurudzira kuvandudzwa kwedhizaini uye kuderedza zvingangoitika zvemhando yepamusoro.

Maitiro ekuongorora maitiro:

Munguva yese yekugadzira maitiro, isu tinoshandisa akasiyana emhando yekuongorora matanho kuti tive nechokwadi chakaenderana uye kuvimbika. Matanho aya anosanganisira:

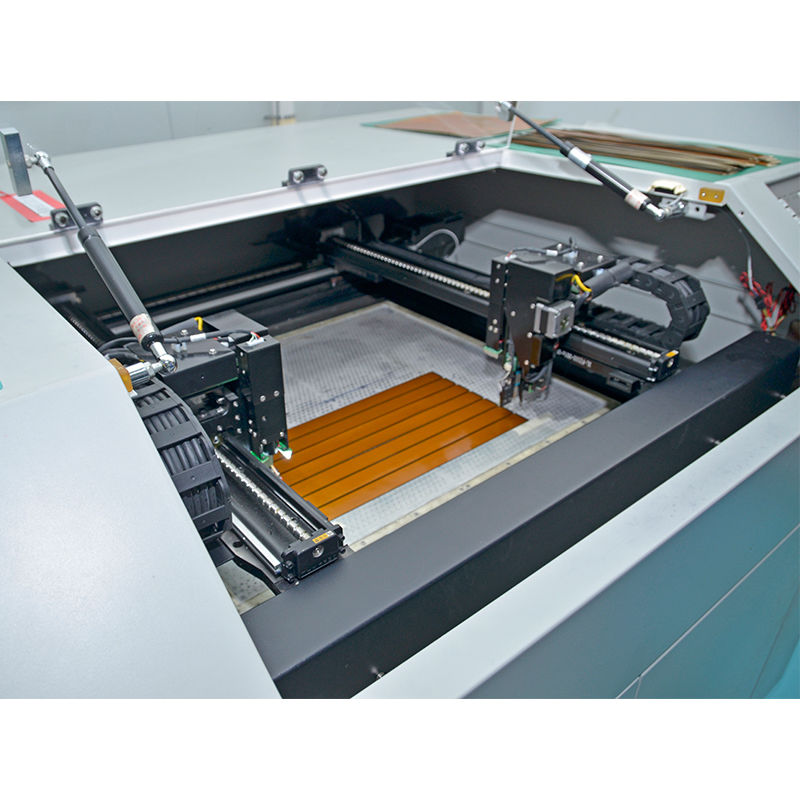

1. Automatic Optical Inspection (AOI): Tichishandisa masisitimu epamusoro eAOI, tinoita ongororo chaiyo yemaPCB pamatanho akakosha, sekunge mushure mekushandisa solder paste, kuiswa kwechikamu nekusodha. AOI inotibvumira kuona zvakakanganisika senge nyaya dzewelding, zvisipo uye kusarongeka zvine hunyoro hwepamusoro uye nehunyanzvi.

2. X-ray kuongorora: Kune maPCB ane zvivako zvakaoma uye kukwirira kwepamusoro, kuongorora X-ray kunoshandiswa kutsvaga kukanganisa kwakavanzika kusingagoni kuwanikwa neziso. Iyi tekinoroji yekuyedza isingaparadzi inotitendera kuti tiongorore majoini ekutengesa, vias uye matinji emukati kune hurema hwakadai sekuvhura, zvikabudura uye voids.

3. Kuongororwa kwemagetsi: Pamberi pegungano rekupedzisira, tinoitisa kuongororwa kwemagetsi kwakazara kuti tive nechokwadi chekushanda uye kuvimbika kwePCB. Miedzo iyi, inosanganisira In-Circuit Testing (ICT) uye bvunzo inoshanda, inotibatsira kuona chero nyaya dzemagetsi kana dzekushanda kuitira kuti dzigadziriswe nekukasira.

4. Kuedza kwezvakatipoteredza: Kuti tive nechokwadi chekugara kwePCBs dzedu pasi pemamiriro akasiyana-siyana ekushanda, tinozviisa pasi pekuedzwa kwakasimba kwezvakatipoteredza. Izvi zvinosanganisira kuchovha bhasikoro, kuyedzwa humidity, kuyedzwa kwemunyu wekupfapfaidza, nezvimwe. Kuburikidza nemiedzo iyi, tinoongorora kuita kwePCB mukupisa kwakanyanya, hunyoro, uye nharaunda dzinoparadza.

Postpartum quality yekuongorora matanho:

Kana nzira yekugadzira yapera, tinoramba tichitora matanho ekuongorora emhando yepamusoro kuti tive nechokwadi chekuti maPCB emhando yepamusoro chete anosvika kune vatengi vedu. Matanho aya anosanganisira:

1. Visual Inspection: Chikwata chedu chine ruzivo chekudzora mhando chinoitisa zvine hungwaru ongororo yekuona kuti ione chero hurema hwekuzora hwakadai sekukwenya, mavara, kana zvikanganiso zvekudhinda. Izvi zvinovimbisa kuti chigadzirwa chekupedzisira chinosanganawo neaesthetic standards.

2. Kuedza kunoshanda: Kuti tisimbise kushanda kwakazara kwePCB, tinoshandisa hunyanzvi hwekuyedza midziyo uye software kuti tiite yakasimba kushanda kwekuyedza. Izvi zvinotitendera kuti tione kushanda kwePCB pasi pemamiriro epasirese uye kuzadzisa zvinodiwa nevatengi vedu.

Mukupedzisa:

Kubva padanho rekutanga rekugadzira kusvika kune yekupedzisira chigadzirwa, kambani yedu inovimbisa isingaenzaniswi yemhando yekudzora matanho mukati mese PCB yekugadzira maitiro. Zvitupa zvedu, zvinosanganisira ISO 14001:2015, ISO 9001:2015 uye IATF16949:2016, pamwe neUL neROHS mamaki, zvinosimbisa kuzvipira kwedu kukuchengetedza kwezvakatipoteredza, kutungamira kwemhando uye kutevedzera mitemo yekuchengetedza.

Pamusoro pezvo, isu tine 16 utility modhi patents uye ekutanga patents, izvo zvinoratidza kushingirira kwedu mukuvandudza uye kuenderera mberi kwekuvandudza. Nekushandisa nzira dzekuongorora dzemhando yepamusoro dzakaita seAOI, kuongorora kweX-ray, kuyedza magetsi, uye kuongorora nharaunda, tinoona kugadzirwa kwePCB dzemhando yepamusoro, dzakavimbika.

Sarudza isu semugadziri wako wePCB akavimbika uye uwane vimbiso yekusagadzikana kwehutongi hwemhando uye sevhisi yakasarudzika yevatengi.

Nguva yekutumira: Oct-30-2023

Back