HDI (High Density Interconnect) rigid-flex PCBs inomiririra iyo yepamusoro yakadhindwa yedunhu tekinoroji tekinoroji, ichibatanidza zvakanakira zvehurefu-density wiring kugona nekuchinjika kweakaomesesa-flex mabhodhi.Ichi chinyorwa chine chinangwa chekujekesa maitiro ekugadzira eHDI rigid-flex PCB uye inopa ruzivo rwakakosha muchimiro chayo, zvigadzirwa uye matanho akakosha ekugadzira.Nekunzwisisa kuomarara kunosanganisirwa, mainjiniya nevagadziri vanogona kukwidziridza dhizaini yavo uye nekubatana zvine mutsindo nevagadziri kuti vashandure mazano avo matsva kuti ave echokwadi.

1.NzwisisaHDI yakasimba inoshanduka PCB:

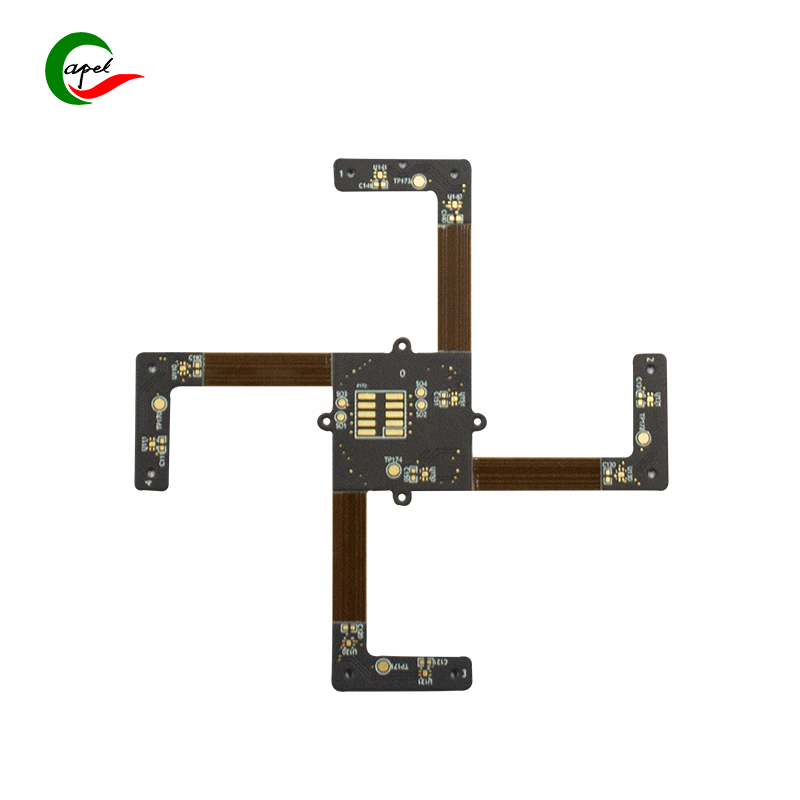

HDI (High Density Interconnect) rigid-flex PCB imhando yepamusoro yeakadhindwa redunhu bhodhi rinobatanidza zvakanakira zvehupamhi-density yekubatanidza uye kuchinjika.Iyi yakasarudzika musanganiswa inoita kuti vanyatsokodzera kusangana nezvinodiwa zvemazuva ano zvemagetsi emidziyo.

High-density yekubatanidza inoreva kugona kuwana yakakwirira-density zvikamu uye chiratidzo chekufambisa mukati mediki bhodhi nzvimbo.Sezvo kudiwa kwezvidiki, zvimwe zvigadziriso zvinoramba zvichikura, HDI tekinoroji inogonesa dhizaini uye kugadzirwa kwemaseketi akaomarara mune madiki fomu zvinhu. Kuwedzera kwekubatanidza density kunobvumira kushanda kwakawanda kuti kusanganisirwe mumidziyo midiki, zvichiita kuti ishande uye ine simba.

Kuchinjika ndechimwe chinhu chakakosha cheHDI rigid-flex PCBs. Uku kuchinjika kunobvumira bhodhi kukotama, kupetwa kana kumonyoroka pasina kukanganisa kuita kana kuvimbika.Kuchinjika kunonyanya kubatsira kumidziyo yemagetsi inoda dhizaini yakaoma yemuviri kana inoda kushingirira kuzunguzika, kuvhunduka, kana nharaunda dzakanyanyisa. Iyo zvakare inogonesa kusanganisa kusanganisa kwemagetsi zvikamu kubva kune akasiyana edunhu bhodhi zvikamu, kubvisa kudiwa kwemamwe majoini kana tambo.

Kushandisa HDI tekinoroji kunopa akati wandei mabhenefiti.Chekutanga, inonatsiridza zvakanyanya kutendeseka kwechiratidzo nekudzikisa chinhambwe pakati pezvikamu uye zvinongedzo, kuderedza kurasikirwa kwechiratidzo, crosstalk uye kupindira kwemagetsi. Izvi zvinosimudzira kuita uye kuvimbika kune yakakwirira-kumhanya yedhijitari uye RF zvikumbiro. Kechipiri, HDI yakaoma-flex PCB inogona kuderedza zvakanyanya saizi uye huremu hwemidziyo yemagetsi. HDI tekinoroji inobvisa kudiwa kwemamwe makubatanidza, tambo, uye bhodhi-kune-bhodhi yekubatanidza, ichibvumira compact, huremu dhizaini. Izvi zvakanyanya kukosha kumaindasitiri akadai seaerospace uye inotakurika yevatengi zvemagetsi, uko kuchengetedza huremu nenzvimbo kwakakosha. Mukuwedzera, teknolojia yeHDI inovandudzawo kuvimbika kwezvigadzirwa zvemagetsi. Nekudzikisa huwandu hwekubatanidza, HDI yakaomesesa-flex PCBs inoderedza njodzi yekutadza nekuda kwekubatana kwakasununguka kana solder joint kuneta. Izvi zvinovandudza kunaka kwechigadzirwa uye zvinowedzera kuvimbika kwenguva refu.

HDI rigid-flex applications inowanikwa mumaindasitiri akasiyana siyana, anosanganisira aerospace, michina yekurapa, nharembozha uye zvemagetsi zvevatengi.Muindasitiri yemuchadenga, maHDI akaomesesa-flex PCB anoshandiswa mumasisitimu ekudzora ndege, maavionics, uye masisitimu ekutaurirana nekuda kwehukuru hwawo compact, huremu huremu, uye kugona kutsungirira mamiriro akanyanya. Mundima yezvokurapa, anoshandiswa mumidziyo yakadai semapacemaker, masisitimu ekufungidzira ekurapa, uye midziyo inoisirwa. Nharembozha uye zvemagetsi zvevatengi zvinobatsira kubva mukudzikiswa saizi uye nekuvandudza mashandiro eHDI rigid-flex PCBs mune smartphones, mahwendefa, zvinopfekeka, uye zvimwe zvinotakurika zvishandiso.

2.HDI yakaoma-inochinjika PCB yekugadzira maitiro: nhanho-ne-nhanho

A. Dhizaini zvinomanikidza uye gadzirira mafaira eCAD:

Danho rekutanga muHDI rigid-flex PCB yekugadzira maitiro ndeye kufunga zvipingaidzo zvekugadzira uye kugadzirira mafaera eCAD. Zvipingamupinyi zvekugadzira zvinoita basa rakakosha pakuona kuita kwePCB, kuvimbika, uye kugadzira. Zvimwe zvakakosha zvipingamupinyi zvekufunga nezvazvo ndezvi:

Size Limitations:

Kukura kwePCB kunoenderana nezvinodiwa zvemudziyo waunoshandiswa. Izvo zvinodikanwa kuve nechokwadi chekuti PCB inokodzera munzvimbo yakatarwa pasina kukanganisa kushanda kana kuvimbika.

Kuvimbika:

PCB dhizaini inofanirwa kuve yakavimbika uye inokwanisa kushingirira inotarisirwa kushanda mamiriro. Zvinhu zvakadai sekushisa, humidity, vibration uye mechanical stress zvinoda kutariswa panguva yekugadzira.

Chiratidzo Kutendeseka:

Madhizaini anofanirwa kufunga nezve kutendeseka kwechiratidzo kudzikisa njodzi yekudzikamisa chiratidzo, ruzha, kana kukanganisa. Yakakwira-kumhanya dhijitari uye RF masiginecha inoda kungwarira nzira uye impedance control.

Thermal Management:

Thermal manejimendi yakakosha kudzivirira kupisa uye kuve nechokwadi chekushanda kwakakwana kwezvinhu zvemagetsi. Kubvisa kupisa kunogona kuwanikwa kuburikidza nekuiswa kwakakodzera kweiyo thermal vias, kupisa kunyura, uye mapedhi ekupisa. CAD software inoshandiswa kugadzira mafaira ePCB. Inobvumira vagadziri kutsanangura layer stacking, chikamu chekuisa uye mhangura yekutsvaga nzira. CAD software inopa maturusi uye kugona kumiririra nemazvo uye kuona magadzirirwo, zvichiita kuti zvive nyore kuziva nekugadzirisa chero matambudziko angangove asati agadzirwa.

B. Kusarudzwa Kwezvinhu uye Kurongeka Dhizaini:

Mushure mekugadzirira mafaera eCAD, danho rinotevera kusarudzwa kwezvinhu uye dhizaini yekugadzira. Kusarudza zvinhu zvakafanira kwakakosha pakuona kuti HDI yakaoma-flex PCBs inowana inodiwa mashandiro emagetsi, kutonga kwekupisa, uye kutendeseka kwemuchina. Rigid layer zvinhu, senge FR-4 kana yakakwira-performance laminates, inopa rutsigiro rwemakanika uye kugadzikana. Iyo inochinjika layer inowanzo gadzirwa ne polyimide kana polyester firimu kuitira kuchinjika uye kusimba. Iyo stackup dhizaini maitiro inosanganisira kuona kurongeka kweakasiyana akaturikidzana, anosanganisira akaomesesa uye anochinjika akaturikidzana, ukobvu hwemhangura, uye dielectric zvinhu. Iyo stackup dhizaini inofanirwa kufunga zvinhu zvakaita sechiratidzo chekuvimbika, impedance control, uye kugovera simba. Kuiswa kwakaringana kwekuisa uye kusarudzwa kwezvinhu kunobatsira kuve nechokwadi chekufambisa kwemasaini, kuderedza crosstalk uye kupa shanduko inodiwa.

C. Laser drilling uye microhole kuumbwa:

Laser drilling inhanho yakakosha mukugadzira yakakwira-density routing microvias muHDI PCBs. Microvias maburi madiki anoshandiswa kubatanidza akasiyana akaturikidzana ePCB, achibvumira yakakwira density yekubatanidza. Laser drilling inopa akati wandei mabhenefiti pamusoro pechinyakare mechini nzira dzekuchera. Iyo inobvumira madiki maapertures, achibvumira kune yakakwira routing density uye yakawanda compact dhizaini. Laser drilling inopawo kunyatsojeka uye kutonga, kuderedza njodzi yekukanganisa kana kukuvadzwa kwezvinhu zvakatenderedza. Mune iyo laser drilling process, yakatarisana nelaser beam inoshandiswa kubvisa zvinhu, kugadzira maburi madiki. Iwo maburi anozoiswa simbi kuti ape conductivity pakati pezvikamu, zvichibvumira kutapurirana kwakanaka kwemasaini.

D. Kuiswa kwekemikari yemhangura:

Electroless copper plating inhanho yakakosha mukugadzira maitiro eHDI rigid-flex board. Maitiro acho anosanganisira kuisa chidimbu chitete chemhangura mukati memicropores uye pamusoro pePCB. Kukosha kwe electroless copper plating kuri mukukwanisa kwayo kuve nechokwadi chekubatana kwemagetsi uye kufambiswa kwakanaka kwechiratidzo. Iyo mhangura yemhangura inozadza iyo microvias uye inobatanidza akasiyana akaturikidzana ePCB, achigadzira nzira inofambisa yezviratidzo. Inopawo nzvimbo inotengeswa yekubatanidza chikamu. Iyo electroless copper plating process inosanganisira akati wandei nhanho, kusanganisira kugadzirira kwepamusoro, activation uye deposition. Iyo PCB inotanga kucheneswa uye kushandiswa kukurudzira kunamatira. Kemikari inogadziriswa inozoshandiswa kuisa mhinduro ine maion emhangura kuPCB pamusoro, ichiisa chidimbu chitete chemhangura.

E. Kutamisa Mufananidzo uye Lithography:

Kufambiswa kwemifananidzo uye photolithography zvikamu zveHDI rigid-flex PCB kugadzira maitiro. Matanho aya anosanganisira kushandisa photoresist zvinhu kugadzira dunhu redunhu paPCB pamusoro uye kuchiisa pachena kune UV mwenje kuburikidza nepatani yefotomask. Munguva yekufambisa kwechifananidzo, photoresist zvinhu zvinoshandiswa kune PCB pamusoro. Photoresist zvinhu zvinonzwa kune UV mwenje uye inogona kusarudzwa pachena. Iyo PCB inozoenderana neyakaomeswa photomask uye UV mwenje inopfuudzwa munzvimbo dzakajeka dzeiyo photomask kuratidza iyo photoresist. Mushure mekuratidzwa, iyo PCB inogadzirwa kuti ibvise iyo isina kuvharwa photoresist, ichisiya yaidiwa dunhu pateni. Aya maitiro anoshanda sematanho ekudzivirira mune zvinotevera maitiro. Kugadzira kutenderera kwedunhu, etching makemikari anoshandiswa kubvisa isingadiwe mhangura. Nzvimbo dzisina kuvharwa nephotoresist dzinoratidzwa kune etchant, iyo inosarudza kubvisa mhangura, ichisiya inodiwa yedunhu.

F. Etching uye electroplating process:

Chinangwa cheiyo etching maitiro ndeye kubvisa yakawandisa mhangura uye kugadzira edunhu reti paHDI rigid-flex PCB. Etching inosanganisira kushandisa etchant, kazhinji asidi kana kemikari mhinduro, kusarudza kubvisa mhangura isingadikanwi. Iyo etching inodzorwa neinodzivirira photoresist layer inodzivirira iyo etchant kubva pakurwisa inodiwa yedunhu. Nyatsodzora nguva uye kusungirirwa kweiyo etchant kuti uwane yaunoda trace hupamhi nekudzika. Mushure mekucheka, iyo yakasara photoresist inobviswa kuti ibudise pachena matunhu edunhu. Kubvisa maitiro kunosanganisira kushandisa zvinonyungudutsa kunyungudutsa uye kubvisa iyo photoresist, ichisiya yakachena uye yakanyatsotsanangurwa yedunhu mitsara. Kuti usimbise kuteedzera kwedunhu uye kuve nechokwadi chekufambisa kwakakodzera, chirongwa cheplating chinodiwa. Izvi zvinosanganisira kuisa imwe dura remhangura padunhu rinoteedzera kuburikidza ne electroplating kana electroless plating process. Ukobvu uye kufanana kwemhangura plating yakakosha pakuwana yakavimbika yekubatanidza magetsi.

G. Solder mask application uye component assembly:

Solder mask application uye chikamu musangano matanho akakosha muHDI rigid-flex PCB kugadzira maitiro. Shandisa solder mask kuchengetedza mavara emhangura uye nekupa insulation pakati pavo. Solder mask inoumba chidziviriro pamusoro pePCB yese pamusoro, isingabatanidzi nzvimbo dzinoda kushambadzira, senge chikamu mapedhi uye vias. Izvi zvinobatsira kudzivirira solder bhiriji uye zvikabudura panguva gungano. Musangano wechikamu unosanganisira kuisa zvinhu zvemagetsi paPCB nekuzvitengesa panzvimbo. Zvikamu zvinoiswa zvakanaka uye zvakamisikidzwa nepedhi yekumhara kuti ive nechokwadi chekubatanidza magetsi. Shandisa nzira dzekutengesa senge reflow kana wave soldering zvichienderana nechikamu chechikamu uye gungano zvinodiwa. Iyo reflow soldering process inosanganisira kudziyisa iyo PCB kune chaiyo tembiricha inoita kuti solder inyunguduke uye igadzire chinongedzo chisingaperi pakati pechikamu chinotungamira uye PCB pads. Wave soldering inowanzo shandiswa kuburikidza-gomba zvikamu, uko iyo PCB inopfuudzwa nepasaisai yeakanyungudutswa solder kuti igadzire chinongedzo.

H. Kuedza uye Kudzora Hunhu:

Danho rekupedzisira muHDI rigid-flex PCB yekugadzira maitiro ndeyekuedza uye kutonga kwemhando. Kuedza kwakasimba kwakakosha kuti uve nechokwadi chePCB kuita, kuvimbika uye kushanda. Ita bvunzo dzemagetsi kutarisa zvikabudura, kuvhura, uye kuenderera mberi. Izvi zvinosanganisira kushandisa chaiyo voltages uye mafungu kuPCB uye kuyera mhinduro uchishandisa otomatiki bvunzo michina. Ongororo yekuona inoitwawo kuona solder joint quality, kuiswa kwechikamu, uye kuchena kwese kwePCB. Inobatsira kuona chero hurema hunogona kuita senge zvisina kurongeka zvikamu, solder mabhiriji, kana zvinosvibisa. Pamusoro pezvo, kuongororwa kwekupisa kwekushushikana kunogona kuitwa kuongorora kugona kwePCB kushingirira tembiricha bhasikoro kana kupisa kwekushisa. Izvi zvinonyanya kukosha mumashandisirwo apo PCB inoratidzwa kune yakanyanyisa tembiricha shanduko. Munguva uye mushure meimwe nhanho yekugadzira, matanho ekudzora emhando anoitwa kuti ave nechokwadi chekuti PCB inosangana nezvinodiwa uye zviyero. Izvi zvinosanganisira yekutarisa maparamendi, kuita nhamba yemaitiro ekudzora (SPC), uye kuita ongororo yenguva nenguva kuona nekugadzirisa chero kukanganisa kana kukanganisa.

3.Matambudziko anotarisana nawo mukugadzira HDI rigid-flex board:

Kugadzira HDI yakaomesesa-flex mabhodhi inopa zvimwe zvinonetsa uye zvinonetsa zvinofanirwa kutariswa nemazvo kuti ive yemhando yepamusoro yekupedzisira chigadzirwa.Aya matambudziko anotenderera munzvimbo nhatu dzakakosha: kurongeka chaiko, kuremara kwepamusoro, uye shanduko ye impedance panguva yekurarisa.

Kurongeka chaiko kwakakosha kune HDI rigid-flex mabhodhi nekuti anosanganisira akati wandei akaturikidzana uye zvinhu zvinofanirwa kuiswa nenzira kwayo. Kuwana kurongeka chaiko kunoda kungwarira kubata uye kugadzika kwezvikamu zvakasiyana kuti ive nechokwadi chekuti vias uye zvimwe zvikamu zvakarongeka. Chero kusarongeka kunogona kukonzera matambudziko makuru akadai sekurasikirwa kwechiratidzo, shorts, kana kuputsika. Vagadziri vanofanirwa kuisa mari mumidziyo yepamberi uye tekinoroji kuti vaone kurongeka chaiko mukati mekuita kwekugadzira.

Kudzivisa kusakanganiswa kwepamusoro ndiro rimwe dambudziko guru. Munguva yekugadzira, kuremara kwepamusoro senge makwara, dents, kana zvinosvibisa zvinogona kuitika, zvichikanganisa mashandiro uye kuvimbika kweHDI rigid-flex board.Izvi zvinokanganisa zvinogona kukanganisa kubatana kwemagetsi, kukanganisa kutendeseka kwechiratidzo, kana kutokonzera kuti bhodhi itadze zvachose. Kuti udzivise kukanganisa kwepamusoro, matanho akasimba ekudzora emhando anofanirwa kutorwa, kusanganisira kubata nekungwarira, kuongororwa nguva dzose, uye kushandiswa kwenzvimbo yakachena panguva yekugadzira.

Kuderedza shanduko ye impedance panguva yelamination kwakakosha kuchengetedza kushanda kwemagetsi kweHDI rigid-flex board.Lamination inosanganisira kushandisa kupisa uye kumanikidza kubatanidza zvidimbu zvakasiyana pamwechete. Nekudaro, maitiro aya anogona kukonzera shanduko mune dielectric inogara uye conductor hupamhi, zvichikonzera zvisingadiwe impedance shanduko. Kudzora nzira yekudzikisa kudzikisa shanduko idzi kunoda kunyatso kudzora tembiricha, kudzvanywa, uye nguva, pamwe nekunyatsoomerera kune zvakatemwa zvekugadzira. Uye zvakare, yepamberi yekuyedza uye yekusimbisa matekiniki anogona kushandiswa kuve nechokwadi chekuti impedance inodiwa inochengetwa.

Kukunda matambudziko aya mukugadzira HDI flex boards kunoda kuti vagadziri nevagadziri vashande pamwe chete mukuita.Vagadziri vanofanirwa kunyatso funga zvipingaidzo zvekugadzira uye nekunyatso taura kune vanogadzira. Nekune rimwe divi, vagadziri vanofanirwa kunzwisisa zvinodikanwa zvekugadzira uye zvipingaidzo kuitira kuti vaite nzira yakakodzera yekugadzira. Kudyidzana kunobatsira kugadzirisa zvingangoitika pakutanga muchikamu chekugadzira uye kuona kuti maitiro ekugadzira anogadziridzwa emhando yepamusoro HDI rigid-flex board.

Mhedziso:

Iyo yekugadzira maitiro eHDI rigid-flex PCB nhevedzano yenhanho dzakaomarara asi dzakakomba dzinoda hunyanzvi, hwakajeka uye hwakavimbika tekinoroji.Kunzwisisa nhanho imwe neimwe yegadziriro inogonesa Capel kukwidziridza kugona kwavo kuendesa yakanakisa kuburitsa mukati menguva dzakasimba. Nekuisa pamberi pekudyidzana dhizaini kuedza, otomatiki uye kuenderera mberi kwekuvandudza maitiro, Capel inogona kugara kumberi kweHDI rigid-flex PCB kugadzira uye kusangana nekukura kuri kudiwa kweakawanda-anoshanda uye epamusoro-kuita mabhodhi mumaindasitiri.

Nguva yekutumira: Sep-15-2023

Back