Munyika yemabhodhi edunhu akadhindwa (PCBs), kusarudzwa kwepamusoro pekupedzisira kwakakosha pakuita kwese uye hupenyu hurefu hwemidziyo yemagetsi. Iko kurapwa kwepamusoro kunopa chivharo chekudzivirira kudzivirira oxidation, kuvandudza solderability, uye kuwedzera kuvimbika kwemagetsi kwePCB. Imwe yakakurumbira PCB mhando ndiyo gobvu yemhangura PCB, inozivikanwa nekugona kwayo kubata yakakwira mitoro iripo uye inopa zvirinani kutonga kwekupisa. Zvisinei,mubvunzo unowanzo kumuka ndewekuti: Ko maPCB akakora emhangura anogona kugadzirwa nemhando dzakasiyana dzepamusoro? Muchinyorwa chino, isu tichaongorora akasiyana epamusoro pekupedzisira sarudzo dziripo kune gobvu mhangura PCB uye kufunga kunosanganisirwa mukusarudza kwakakodzera kupedzisa.

1.Dzidza nezve Heavy Copper PCBs

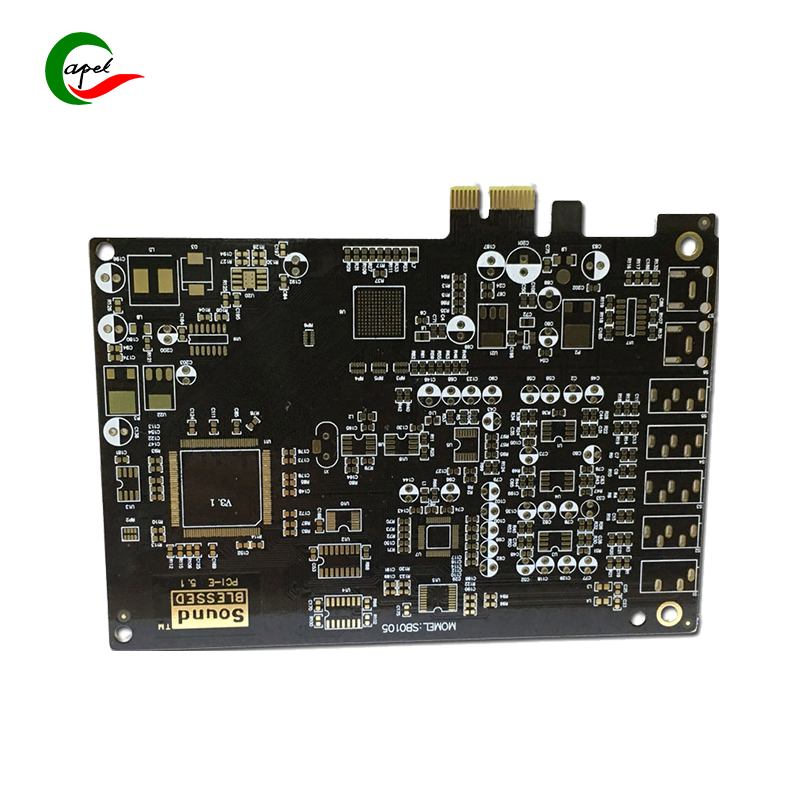

Usati waongorora sarudzo dzekupedzisira, zvinodikanwa kuti unzwisise kuti PCB yakakora yemhangura chii uye maitiro ayo chaiwo. Kazhinji, maPCB ane hukobvu hwemhangura akakura kupfuura 3 ounces (105 µm) anonzi maPCB akakora emhangura. Aya mapuranga akagadzirirwa kutakura mafungu akakwirira uye kubvisa kupisa zvakanaka, izvo zvinoita kuti zvive zvakakodzera magetsi emagetsi, motokari, kushandiswa kwemhepo uye zvimwe zvigadzirwa zvine simba guru rinodiwa. Makobvu emhangura PCB anopa yakanakisa yekupisa conductivity, yakakwira mechanika simba uye yakaderera voltage kudonha pane yakajairwa maPCB.

2.Kukosha kwepamusoro kurapwa muHeavy Copper Pcb Manufacturing:

Kugadzirira kwepamusoro kunoita basa rakakosha mukuchengetedza maronda emhangura uye mapedhi kubva kune oxidation uye kuve nechokwadi chekuti majoini akavimbika anotengeswa. Vanoita sechipingamupinyi pakati pemhangura yakafumurwa uye yekunze zvikamu, kudzivirira kuora uye kuchengetedza solderability. Pamusoro pezvo, kupedzisa kwepamusoro kunobatsira kupa nzvimbo yakati sandara yekuisa chikamu uye nzira dzekubatanidza waya. Kusarudza iyo chaiyo yepasi pekupedzisira kune gobvu mhangura PCB kwakakosha kukwenenzvera kuita kwavo uye kuvimbika.

3.Surface kurapwa sarudzo dzeHeavy Copper PCB:

Kupisa kwemhepo solder kuyera (HASL):

HASL ndeimwe yeakanyanya tsika uye inodhura-inoshanda PCB pamusoro pekurapa sarudzo. Mukuita uku, PCB inonyudzwa mubhavhu resimbi yakanyungudutswa uye iyo yakawandisa solder inobviswa uchishandisa banga rinopisa remhepo. Iyo yakasara solder inoumba danda gobvu pamusoro pemhangura, ichidzivirira kubva pakuora. Kunyangwe HASL iri nzira inoshandiswa zvakanyanya pamusoro pekurapa, haisiriyo sarudzo yakanakisa yemaPCB emhangura yakakora nekuda kwezvikonzero zvakasiyana. Iyo yakanyanya tembiricha yekushanda inosanganisirwa mukuita uku inogona kukonzera kushushikana kwekupisa pamatanda akakora emhangura, zvichikonzera warping kana delamination.

Electroless nickel kunyudza goridhe plating (ENIG):

ENIG isarudzo yakakurumbira yekurapa kwepamusoro uye inozivikanwa nekunaka kwayo weldability uye corrosion resistance. Zvinosanganisira kuisa mutsetse mutete we electroless nickel wobva waisa mutsetse wegoridhe rekunyudza pamusoro pemhangura. ENIG ine yakadzikama, yakatsetseka pamusoro pekupedzisira, ichiita kuti ive yakakodzera kune yakatsetseka-pitch zvikamu uye waya yegoridhe bonding. Nepo ENIG ichigona kushandiswa paPCB dzakakora dzemhangura, zvakakosha kuti titarise ukobvu hwegoridhe dhizaini kuti uve nechokwadi chekuchengetedzwa kwakaringana kubva pamhepo yakakwira uye nemhedzisiro yekupisa.

Electroless Nickel Plating Electroless Palladium Immersion Gold (ENEPIG):

ENEPIG ndeyepamusoro pepamusoro kurapwa iyo inopa yakanakisa solderability, corrosion resistance uye wire bondability. Zvinosanganisira kuisa musara we electroless nickel, ipapo musara we electroless palladium, uye pakupedzisira dhiri rekunyudzwa kwegoridhe. ENEPIG inopa kusimba kwakanyanya uye inogona kuiswa kune gobvu mhangura PCB. Iyo inopa yakaomeswa pamusoro pekupedzisira, ichiita kuti ive yakakodzera kune yakakwirira-simba maapplication uye yakanaka-pitch zvikamu.

Immersion tin (ISn):

Immersion tin ndiyo imwe nzira yekurapa pamusoro pemaPCB akakora emhangura. Inonyudza PCB mumushonga we-tin-based, ichigadzira chidimbu cherata pamusoro pemhangura. Immersion tin inopa yakanakisa solderability, nzvimbo yakati sandara, uye inoenderana nenharaunda. Nekudaro, chimwe chekufungisisa paunenge uchishandisa kunyudza tini paPCB dzakakora dzemhangura ndechekuti ukobvu hwetinhi hunofanira kunyatsodzorwa kuti ive nechokwadi chekuchengetedzwa kwakaringana kubva kuoxidation uye kuyerera kwakanyanya kwazvino.

Organic solderability preservative (OSP):

OSP mushonga wepamusoro unogadzira inodzivirira organic coating pane yakavhurika yemhangura. Iine yakanaka solderability uye inodhura. OSP inokodzera maapplication emagetsi epasi kusvika epakati uye inogona kushandiswa pamaPCB akakora emhangura chero zvazvino kutakura kutakura uye zvinodikanwa zvekuraswa kwemafuta zvichizadzikiswa. Chimwe chezvinhu zvekufunga nezvazvo paunenge uchishandisa OSP paPCB yakakora yemhangura ndeyekuwedzera ukobvu hweiyo organic coating, iyo inogona kukanganisa mashandiro emagetsi nekupisa.

4.Zvinhu zvekufunga kana uchisarudza kupedzisa kwepamusoro kune Heavy Copper PCBs: Pakusarudza iyo yepamusoro kupedzisa kune Inorema.

Mhangura PCB, pane zvinhu zvakawanda zvekufunga nezvazvo:

Ikozvino Kutakura Kugona:

Makobvu emhangura maPCB anonyanya kushandiswa mukushandisa simba repamusoro, saka zvakakosha kuti usarudze kupera kwepamusoro kunogona kubata mitoro yakakwira pasina kupokana kana kupisa. Sarudzo dzakadai se ENIG, ENEPIG, uye kunyudza tin zvinowanzokodzera maapplication azvino.

Thermal Management:

Gobvu mhangura PCB inozivikanwa nekunaka kwayo yekupisa conductivity uye kupisa kwekupisa simba. Iyo yekupedzisa kwepamusoro haifanire kutadzisa kupisa kutamisa kana kukonzera yakawandisa thermal kusagadzikana pane yemhangura layer. Kurapa kwepamusoro senge ENIG uye ENEPIG ine zvidimbu zvitete izvo zvinowanzo batsira kutungamira kwekupisa.

Solderability:

Kupedzwa kwepamusoro kunofanirwa kupa yakanakisa solderability kuti ive yakavimbika solder majoini uye basa rakakodzera rechikamu. Sarudzo senge ENIG, ENEPIG uye HASL inopa yakavimbika solderability.

Component Compatibility:

Funga kuenderana kweiyo yakasarudzwa pamusoro pekupedzisira neiyo chaiyo zvikamu zvichaiswa paPCB. Yakanaka pitch zvikamu uye goridhe waya yekubatanidza ingangoda kurapwa kwepamusoro senge ENIG kana ENEPIG.

Mutengo:

Mutengo unogara uchitariswa kwakakosha mukugadzira PCB. Mutengo wekurapwa kwakasiyana kwepamusoro unosiyana nekuda kwezvinhu zvakaita semutengo wezvinhu, kuomarara kwemaitiro uye michina inodiwa. Ongorora mutengo wekukanganisa kweakasarudzwa pamusoro pekupedzisira pasina kukanganisa kuita uye kuvimbika.

Makobvu emhangura PCB anopa zvakasarudzika mabhenefiti epamusoro-simba maapplication, uye kusarudza iyo chaiyo yepamusoro kupedzisa kwakakosha kukwenenzvera kuita kwavo uye kuvimbika.Nepo sarudzo dzechivanhu dzakaita seHASL dzinogona kunge dzisina kukodzera nekuda kwenyaya dzekupisa, kurapwa kwepamusoro senge ENIG, ENEPIG, kunyudza tin uye OSP kunogona kutariswa zvichienderana nezvinodiwa chaizvo. Zvinhu zvakadai sekugona kutakura kwazvino, kutungamira kwemafuta, solderability, kuenderana kwechikamu uye mutengo unofanirwa kuongororwa pakusarudza kupedzisa kwemaPCB akakora emhangura. Nekuita sarudzo dzakangwara, vagadziri vanogona kuve nechokwadi chekubudirira kugadzira uye kushanda kwenguva refu kwekobvu yemhangura PCB mumhando dzakasiyana dzemagetsi nemagetsi.

Nguva yekutumira: Sep-13-2023

Back