Delamination muPCB inogona kutungamira kune akakosha kuita nyaya, kunyanya muakaomesesa-flex dhizaini apo zvese zvakaomarara uye zvinochinjika zvinhu zvinosanganiswa. Kunzwisisa nzira yekudzivirira delamination kwakakosha pakuona hupenyu hurefu uye kuvimbika kweaya magungano akaoma. Ichi chinyorwa chichaongorora matipi anoshanda ekudzivirira PCB delamination, yakatarisana nePCB lamination, kuenderana kwezvinhu, uye yakagadziridzwa machining paramita.

Kunzwisisa PCB Delamination

Delamination inoitika kana zvikamu zvePCB zvakaparadzana nekuda kwezvikonzero zvakasiyana, zvinosanganisira kushushikana kwekushisa, kunyudza hunyoro, uye kunetsa kwemuchina. Mune yakaomesesa-flex PCBs, dambudziko rinokwidziridzwa nekuda kwekusiyana kwezvinhu zvakaomarara uye zvinochinjika zvinhu. Naizvozvo, kuve nechokwadi chekuenderana pakati pezvinhu izvi inhanho yekutanga mukudzivirira delamination.

Ita shuwa PCB Material Kuenderana

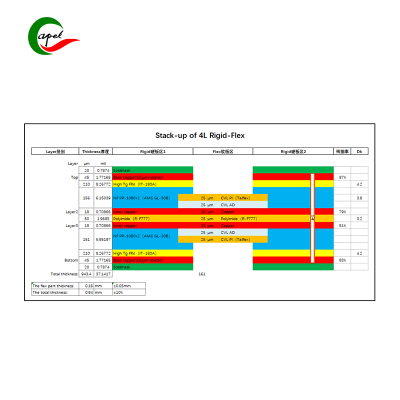

Kusarudzwa kwezvinhu zvakakosha mukudzivirira delamination. Paunenge uchigadzira yakaomesesa-flex PCB, zvakakosha kuti usarudze zvinhu zvine akafanana ekuwedzera ekupisa coefficients. Uku kuwirirana kunoderedza kushushikana panguva yekupisa bhasikoro, izvo zvinogona kutungamira kune delamination. Uyezve, funga iyo yakanamatira inoshandiswa mukugadzirisa lamination. Yepamusoro-mhando yekunamira iyo yakanyatso kugadzirirwa yakaomesesa-flex application inogona kuwedzera zvakanyanya kusimba kwechisungo pakati pematanho.

PCB Lamination process

Iyo lamination process inhanho yakakosha mukugadzira PCB. Lamination yakakodzera inovimbisa kuti zvidimbu zvinonamatirana zvakanaka kune mumwe nemumwe, zvichideredza njodzi yekudonha. Heano mamwe matipi anoshanda eiyo inoshanda PCB lamination:

Tembiricha uye Kudzora Kudzvinyirira: Ita shuwa kuti iyo lamination process inoitwa pane chaiyo tembiricha uye kumanikidza. Kunyanya kupisa kwekushisa kunogona kukanganisa zvinhu, asi kusakwana kumanikidzika kunogona kukonzera kunamatira kusina kunaka.

Vacuum Lamination: Kushandisa vacuum panguva yekutsvaira kunogona kubatsira kubvisa mabhubhu emhepo anogona kukonzera kushaya simba muchibvumirano. Iyi tekinoroji inovimbisa kuwedzera yunifomu kudzvanywa paPCB maseru.

Nguva Yekudyara: Bvumira nguva yakaringana yekurapa yekunamatira kuti ibatane zvakanaka. Kumhanyisa maitiro aya kunogona kutungamira kune isina kukwana kunamatira, kuwedzera njodzi yeku delamination.

Yakagadziridzwa Rigid-Flex PCB Machining Parameters

Machining paramita inoita basa rakakosha mukutendeseka kweakaomesesa-flex PCBs. Heano mamwe akagadziridzwa machining matipi ekudzivirira delamination:

Drilling Techniques: Shandisa zvakakodzera mabheti ekudhirowa uye kumhanya kudzikisa kupisa chizvarwa panguva yekuchera. Kupisa kwakanyanya kunogona kuderedza chisungo chekunamatira uye kutungamirira kune delamination.

Kufambisa uye Kucheka: Paunenge uchifambisa kana kucheka PCB, ita shuwa kuti maturusi akapinza uye akachengetedzwa zvakanaka. Zvishandiso zvisina kusimba zvinogona kukonzera kudzvinyirira kwakanyanya uye kupisa, kukanganisa kutendeseka kwezvikamu.

Edge Treatment: Nyatsobata mipendero yePCB mushure mekugadzira. Izvi zvinogona kusanganisira kutsvedzerera kana kuisa chisimbiso kumapendero kudzivirira hunyoro huchipinda, izvo zvinogona kuita kuti delamination nekufamba kwenguva.

Mazano Anoshanda Ekudzivirira PCB Delamination

Mukuwedzera kune mazano ari pamusoro apa, funga mazano anotevera anoshanda:

Environmental Control: Chengetedza maPCB munzvimbo inodzorwa kudzivirira kunyudza hunyoro. Humidity inogona kuderedza chisungo chekunamatira uye kutungamirira kune delamination.

Regular Testing: Ita bvunzo dzenguva dzose dzePCB dzezviratidzo zve delamination panguva yekugadzira. Kukurumidza kuona kunogona kubatsira kuderedza nyaya dzisati dzawedzera.

Kudzidziswa uye Kuziva: Ita shuwa kuti vese vashandi vanobatanidzwa muPCB kugadzira maitiro vakadzidziswa mune akanakisa maitiro e lamination uye machining. Kuziva kwezvinhu zvinokonzeresa delamination kunogona kutungamira mukuita sarudzo kuri nani.

Nguva yekutumira: Oct-31-2024

Back