suma:

Tikugashirei kune imwe inodzidzisa blog post kubva kuCapel, mutambi ane mukurumbira muindasitiri yedunhu redunhu kwemakore gumi nemashanu apfuura.Muchinyorwa chino, isu tichakurukura kugona uye zvakanakira kushandisa pamusoro mount zvikamu muPCB board prototyping mapurojekiti.Semugadziri anotungamira, isu tine chinangwa chekupa nekukurumidza PCB prototyping kugadzirwa, wedunhu bhodhi prototype musangano masevhisi uye yakazara-yekumira mhinduro kune zvese zvaunoda bhodhi redunhu.

Chikamu 1: Kunzwisisa Nheyo dzeSurface Mount Zvikamu

Surface mount components, inozivikanwawo seSMD (surface mount device) zvikamu, zviri kuramba zvichizivikanwa muindasitiri yezvemagetsi nekuda kwehukuru hwadzo, kubatanidza otomatiki uye mutengo wakaderera. Kusiyana nemaitiro echinyakare kuburikidza ne-gomba zvikamu, SMD zvikamu zvakaiswa zvakananga paPCB pamusoro, kuderedza nzvimbo inodiwa uye kugonesa miniaturization yemidziyo yemagetsi.

Chikamu 2: Zvakanakira kushandisa pamusoro pegomo zvikamu muPCB board prototyping

2.1 Kushandiswa kwakanaka kwenzvimbo: Iyo compact size yeSMD components inogonesa yakakwirira chikamu density, ichibvumira vagadziri kugadzira madiki, akareruka maseketi pasina kukanganisa kushanda.

2.2 Kuvandudzwa kwekuita kwemagetsi: Surface gomo tekinoroji inopa mapfupi makwara azvino, kuderedza parasitic inductance, kuramba uye capacitance. Nekuda kweizvozvo, izvi zvinovandudza kutendeseka kwechiratidzo, zvinoderedza ruzha, uye zvinowedzera kushanda kwemagetsi kwese.

2.3 Mutengo-Kubudirira: Zvikamu zveSMD zvinogona kuve nyore otomatiki panguva yegungano, nekudaro kuderedza nguva yekugadzira uye mutengo. Pamusoro pezvo, saizi yavo diki inoderedza mari yekutumira uye yekuchengetedza.

2.4 Kuwedzeredzwa kwesimba remagetsi: Nekuti pamusoro pegomo zvikamu zvakanamirwa zvakananga kuPCB pamusoro, zvinopa hukuru hwemagetsi kugadzikana, zvichiita kuti dunhu rirambe rinopesana nekushushikana kwezvakatipoteredza uye vibration.

Chikamu 3: Mafungiro uye Zvinetso zveKuunza Surface Mount Zvikamu muPCB Board Prototyping.

3.1 Dhizaini Mirayiridzo: Kana uchibatanidza zvikamu zveSMD, vagadziri vanofanirwa kutevedzera nhungamiro chaiyo kuti vaone kurongeka kwakaringana, kurongeka kwechikamu, uye kutendeseka kwekutengesa panguva yekuungana.

3.2 Soldering tekinoroji: Surface gomo zvikamu zvinowanzo shandisa reflow soldering tekinoroji, iyo inoda hunyanzvi michina uye inodzorwa tembiricha mbiri. Kuwedzera kutarisirwa kunofanira kutorwa kudzivirira kupisa kana kusakwana majoini e solder.

3.3 Kuwanikwa kwechikamu uye Sarudzo: Nepo zvikamu zvemugomo zviri kuwanikwa zvakanyanya, zvakakosha kufunga zvinhu zvakaita sekuwanikwa, nguva yekutungamira, uye kuenderana kana uchisarudza zvikamu zvePCB board prototyping.

Chikamu chechina: Capel inogona kukubatsira sei kubatanidza pamusoro pegomo zvinhu

PaCapel, isu tinonzwisisa kukosha kwekugara tichiziva nezvezvino kufambira mberi kwetekinoroji. Neruzivo rwedu rwakakura muPCB board prototyping uye gungano, tinopa rutsigiro rwakakwana uye zvigadziriso zvetsika kubatanidza zvinhu zvekumusoro mumadhizaini ako.

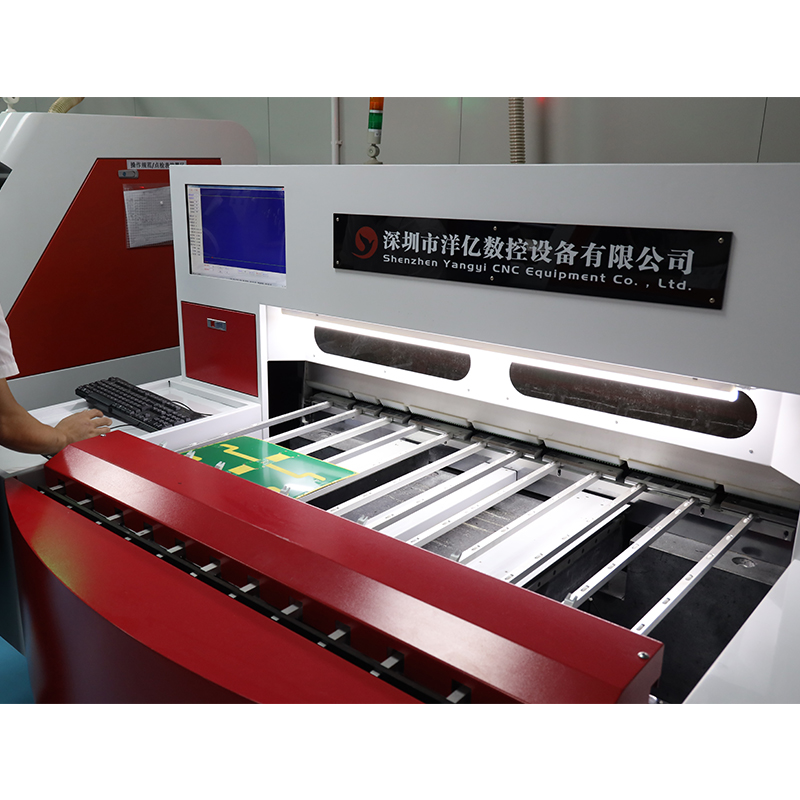

4.1 Advanced Manufacturing Facility: Capel ine nzvimbo yemazuva ano yekugadzira yakashongedzerwa nemichina yekucheka-cheka inoita kuti tikwanise kubata maitiro akaoma emusangano wepamusoro nekunyatso uye nekubudirira.

4.2 Component Procurement: Isu takagadzira hukama hwekudyidzana nevashambadziri vane mukurumbira wechikamu kuti tive nechokwadi chekuti tinopa zvinhu zvemhando yepamusoro zvepamhepo zvePCB board prototyping project yako.

4.3 Chikwata Chine Unyanzvi: Capel ine timu yevanyanzvi vane hunyanzvi uye mainjiniya vane hunyanzvi hwekugadzirisa matambudziko ane chekuita nekubatanidza zvikamu zvegomo. Iva nechokwadi chekuti purojekiti yako ichaitwa nekuchenjerera uye nehunyanzvi.

Mukupedzisa:

Kushandisa nzvimbo dzepamusoro dzepamusoro muPCB board prototyping kunogona kuunza zvakawanda zvakanaka, senge kugadzikana kukuru kwemuchina, kuvandudza kushanda kwemagetsi, kuwedzera kushanda zvakanaka uye kuita mari. Nekubatana naCapel, mugadziri anotungamira muindasitiri yedhipatimendi redunhu, unogona kukwidziridza hunyanzvi hwedu, zvivakwa zvekugadzira zvepamberi uye yakazara turnkey mhinduro kurerutsa rwendo rwako kune yakabudirira pamusoro pekubatanidza gomo. Bata isu nhasi kuti udzidze mashandisiro atingaite iwe nePCB board prototyping yako kuedza.

Nguva yekutumira: Oct-16-2023

Back