Mukugadzira zvemagetsi, surface Mount Technology (SMT) musangano ndeimwe yematanho akakosha ekubudirira kugadzirwa kwemidziyo yemagetsi.Gungano reSMT rinoita basa rakakosha muhupamhi hwese, kuvimbika uye kugona kwezvigadzirwa zvemagetsi. Kuti ikubatsire kunzwisisa zviri nani uye kujairana nePCB gungano, Capel ichakutungamira kuti uongorore izvo zvekutanga zveSMT refactoring. uye kurukura kuti sei zvakakosha mukugadzira zvemagetsi.

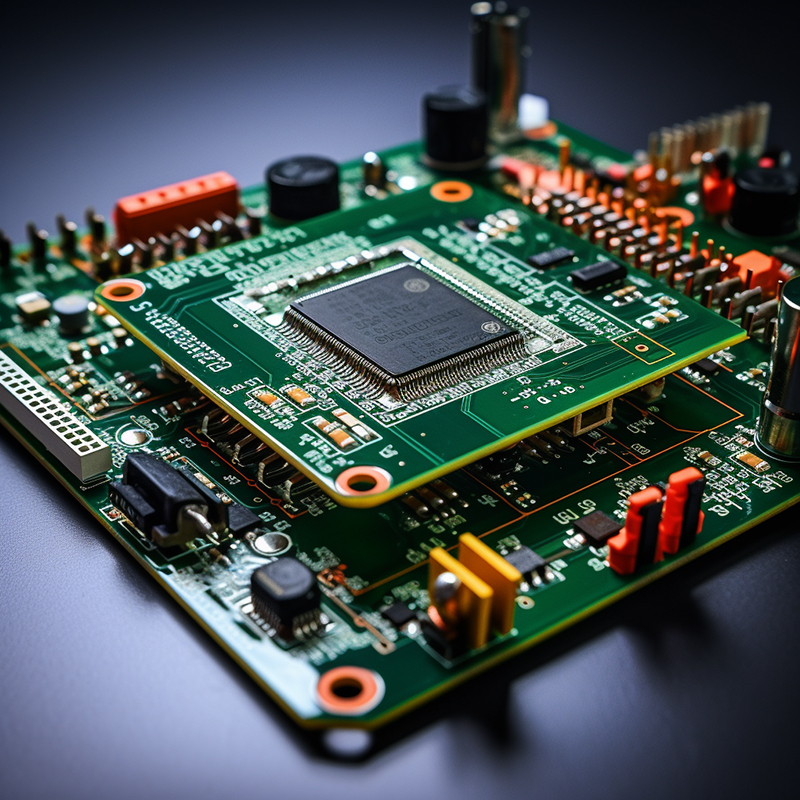

Gungano reSMT, rinozivikanwawo sesurface mount assembly, inzira yekuisa zvinhu zvemagetsi pamusoro pebhodhi redunhu rakadhindwa (PCB).Kusiyana neyakajairwa kuburikidza-gomba tekinoroji (THT), iyo inopinza zvikamu kuburikidza nemakomba muPCB, SMT musangano unosanganisira kuisa zvikamu zvakananga pamusoro pebhodhi. Mumakore achangopfuura, tekinoroji iyi yakawana mukurumbira wakapararira nekuda kwekuwanda kwayo kwakanakira pamusoro peTHT, senge yakakwira chikamu density, diki bhodhi saizi, yakagadziridzwa chiratidzo chekuvimbika, uye kuwedzera kukurumidza kugadzira.

Zvino, ngationgororei mune izvo zvekutanga zveSMT musangano.

1. Kuiswa kwechikamu:Danho rekutanga mumusangano weSMT rinosanganisira kuiswa chaiko kwezvikamu zvemagetsi paPCB. Izvi zvinowanzoitwa pachishandiswa pikicha-ne-nzvimbo muchina unotora otomatiki zvikamu kubva kune yekudyisa uye wozviisa nemazvo pabhodhi. Kuiswa kwakakodzera kwezvikamu zvakakosha kuti kuve nechokwadi chekushanda kwakakodzera uye kuvimbika kwemidziyo yemagetsi.

2. Solder paste application:Mushure mekuisa zvinhu, shandisa solder paste (musanganiswa we solder particles uye flux) kumapadhi ePCB. Solder paste inoshanda sechinhu chinonamira kwenguva pfupi, inobata zvikamu panzvimbo isati yaiswa. Inobatsirawo kugadzira kubatana kwemagetsi pakati pechikamu nePCB.

3. Reflow soldering:Nhanho inotevera mumusangano we SMT ndeye reflow soldering. Izvi zvinosanganisira kudziyisa PCB nenzira inodzorwa kunyungudutsa solder paste uye kugadzira chisingaperi solder joint. Reflow soldering inogona kuitwa uchishandisa nzira dzakasiyana senge convection, infrared radiation kana vapor phase. Munguva iyi, solder paste inoshanduka kuita yakanyungudutswa, inoyerera ichienda kune chikamu chinotungamira uye PCB pads, uye inoomesa kuti iite yakasimba solder yekubatanidza.

4. Kuongorora uye kutonga kwehutano:Mushure mekunge nzira yekutengesa yapera, PCB ichapfuura nekuongorora kwakasimba uye matanho ekugadzirisa hutano kuti ave nechokwadi chokuti zvikamu zvose zvakaiswa zvakanaka uye majoini ekutengesa ndeemhando yepamusoro. Automated Optical Inspection (AOI) uye maX-ray ekuongorora maitiro anowanzo shandiswa kuona chero chakakanganisika kana kukanganisa mugungano. Chero kusawirirana kunowanikwa panguva yekuongorora kunogadziriswa PCB isati yaenda kune inotevera nhanho yekugadzira.

Saka, nei gungano reSMT rakakosha mukugadzira zvemagetsi?

1. Kubudirira kwemitengo:Gungano reSMT rine mukana wemubhadharo pamusoro peTHT sezvo ichideredza nguva yese yekugadzira uye inorerutsa maitiro ekugadzira. Iko kushandiswa kweotomatiki michina yekuisa chikamu uye solder inovimbisa kugadzirwa kwepamusoro uye kuderera kwemitengo yevashandi, zvichiita kuti ive sarudzo ine hupfumi inogoneka mukugadzirwa kwehuwandu.

2. Miniaturization:Iyo yekuvandudza maitiro emidziyo yemagetsi idiki uye yakawanda compact midziyo. SMT musangano inogonesa miniaturization yemagetsi nekumisikidza zvikamu zvine diki tsoka. Izvi hazvingowedzere kutakurika, asiwo zvinovhura mikana mitsva yekugadzira kune vanogadzira zvigadzirwa.

3. Kuvandudzwa kwekuita:Sezvo zvikamu zveSMT zvakaiswa zvakananga paPCB pamusoro, nzira shoma dzemagetsi dzinobvumira kutendeseka kwechiratidzo chiri nani uye kuwedzera kushanda kwezvigadzirwa zvemagetsi. Iko kuderedzwa kweparasitic capacitance uye inductance inoderedza kurasikirwa kwechiratidzo, crosstalk uye ruzha, kuvandudza kushanda kwese.

4. Higher component density:Kuenzaniswa neTHT, SMT musangano unogona kuwana yakakwira chikamu density paPCB. Izvi zvinoreva kuti mamwe mabasa anogona kubatanidzwa munzvimbo diki, zvichigonesa kuvandudzwa kwezvakaoma uye zvakapfuma zvemagetsi zvigadzirwa. Izvi zvinonyanya kukosha mumaindasitiri umo nzvimbo inowanzoganhurwa, senge nharembozha, zvemagetsi zvevatengi, uye midziyo yekurapa.

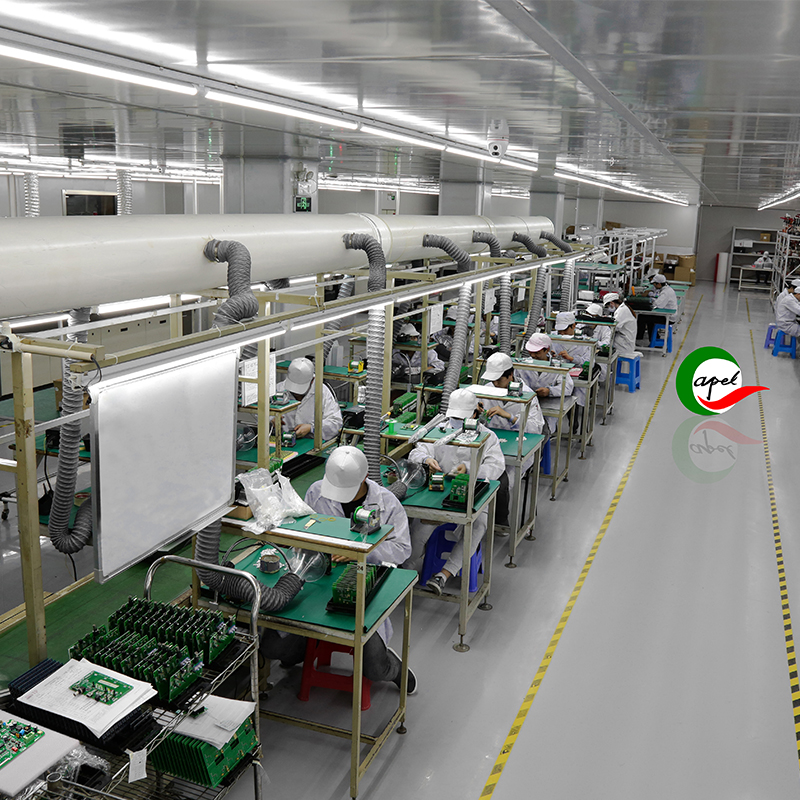

Kubva pane ongororo iri pamusoro,kunzwisisa izvo zvekutanga zveSMT musangano kwakakosha kune chero munhu anobatanidzwa mukugadzira zvemagetsi. Gungano reSMT rinopa akawanda mabhenefiti pamusoro pechinyakare kuburikidza-gomba tekinoroji, kusanganisira mutengo wakanaka, miniaturization kugona, kuvandudza mashandiro, uye yakakwirira chikamu density. Sezvo kudiwa kwezvinhu zvidiki, zvinokurumidza, uye zvakavimbika zvemagetsi zvichiramba zvichikura, gungano reSMT richaita basa rinowedzera kukosha mukuzadzisa izvi zvinodiwa.Shenzhen Capel Technology Co., Ltd. ine fekitori yayo yePCB yegungano uye yakapa basa iri kubva muna 2009. Nemakore gumi nemashanu eruzivo rwepurojekiti yakapfuma, kuyerera kwakasimba, kugona kwakanakisa kwehunyanzvi, midziyo yemhando yepamusoro, hurongwa hwekutonga hwemhando yepamusoro, uye Capel ane inyanzvi yehunyanzvi timu yekupa vatengi vepasirese nepamusoro-chaiyo, yepamusoro-soro inokurumidza kutendeuka PCB Assemble prototyping. Zvigadzirwa izvi zvinosanganisira inochinjika PCB gungano, yakasimba PCB gungano, rigid-flex PCB gungano, HDI PCB gungano, yakakwirira-frequency PCB gungano uye yakakosha maitiro PCB gungano. Yedu inoteerera pre-kutengesa uye post-kutengesa tekinoroji masevhisi uye kuendesa panguva inogonesa vatengi vedu kukurumidza kubata mikana yemusika yemapurojekiti avo.

Nguva yekutumira: Aug-24-2023

Back