suma:

Mukugadzira zvemagetsi, soldering inoita basa rakakosha mukuona kuvimbika uye kuita kweakadhindwa edunhu mabhodhi (PCBs). Capel ane makore gumi nemashanu eruzivo rweindasitiri uye anotungamira mupi wepamusoro PCB solder mhinduro.Mugwaro rino rakazara, isu tichaongorora akasiyana siyana ekutengesa uye matekiniki anoshandiswa mukugadzira PCB, tichiratidza hunyanzvi hweCapel uye tekinoroji yepamberi.

1. Kunzwisisa PCB soldering: Overview

PCB soldering inzira yekubatanidza zvinhu zvemagetsi kuPCB uchishandisa solder, alloy yesimbi inonyunguduka pakudziya kwakadzika kuita chisungo. Maitiro aya akakosha mukugadzira PCB sezvo ichivimbisa kufambiswa kwemagetsi, kugadzikana kwemuchina uye kutonga kwekupisa. Pasina soldering yakakodzera, PCB inogona kusashanda kana kuita zvisina kunaka.

Kune marudzi mazhinji ehunyanzvi hwekutengesa anoshandiswa mukugadzira PCB, imwe neimwe iine maapplication ayo zvichienderana nezvinodiwa chaizvo zvePCB. Aya matekinoroji anosanganisira surface mount technology (SMT), kuburikidza negomba tekinoroji (THT) uye hybrid tekinoroji. SMT inowanzo shandiswa kuzvinhu zvidiki, nepo THT inosarudzwa kune yakakura uye yakasimba zvikamu.

2. PCB welding teknolojia

A. Traditional welding tekinoroji

Single uye kaviri-sided welding

Single-sided uye kaviri-sided soldering nzira dzinoshandiswa zvakanyanya mukugadzira PCB. Single-sided soldering inobvumira zvikamu kuti zvitengeswe kune rimwe divi rePCB, nepo maviri-sided soldering inobvumira zvikamu kuti zvitengeswe pamativi ese.

Iyo imwe-sided solder process inosanganisira kuisa solder paste kuPCB, kuisa pamusoro peiyo mount components, uyezve kuyerera solder kugadzira chisungo chakasimba. Iyi tekinoroji inokweretesa kune yakapfava PCB dhizaini uye inopa mabhenefiti akadai sekudhura-kushanda uye nyore kuungana.

Kaviri-side soldering,kune rumwe rutivi, zvinosanganisira kushandisa kuburikidza-mugomba zvikamu zvinotengeswa kumativi ose ePCB. Iyi teknolojia inowedzera kugadzikana kwemagetsi uye inobvumira kubatanidzwa kwezvimwe zvikamu.

Capel inonyanya kushandisa nzira dzakavimbika-uye mbiri-sided welding,kuve nechokwadi chemhando yepamusoro uye chaiyo mukuita welding.

Multilayer PCB soldering

Multilayer PCBs inoumbwa neakawanda akaturikidzana emhangura inoteedzerwa uye insulating zvinhu, zvinoda nyanzvi dzekutengesa matekiniki. Capel ine ruzivo rwakakura rwekubata mapurojekiti akaomesesa akawanda-layer welding, kuve nechokwadi chekubatana kwakavimbika pakati pematanho.

Iyo multilayer PCB solder process inosanganisira kuchera maburi mune yega yega yePCB uye wozoisa iwo maburi nezvinhu zvinoitisa. Izvi zvinobvumira kuti zvikamu zvitengeswe pamatanda ekunze apo uchichengetedza kuwirirana pakati pezvikamu zvemukati.

B. Advanced welding tekinoroji

HDI PCB kutengesa

High-density interconnect (HDI) maPCB ari kuramba achizivikanwa nekuda kwekugona kwavo kugarisa zvimwe zvikamu muzvikamu zvidiki zvemafomu. HDI PCB solder tekinoroji inogonesa kunyatso tengesa kwezvidiki-zvikamu mune yakakwirira-density marongero.

HDI PCBs dzinosangana nematambudziko akasarudzika akadai seyakaomesesa chikamu chepakati, yakanaka-pitch zvikamu, uye kudiwa kweiyo microvia tekinoroji. Capel's advanced process tekinoroji inogonesa chaiyo HDI PCB soldering, kuve nechokwadi chemhando yepamusoro uye kuvimbika kune aya akaomarara PCB dhizaini.

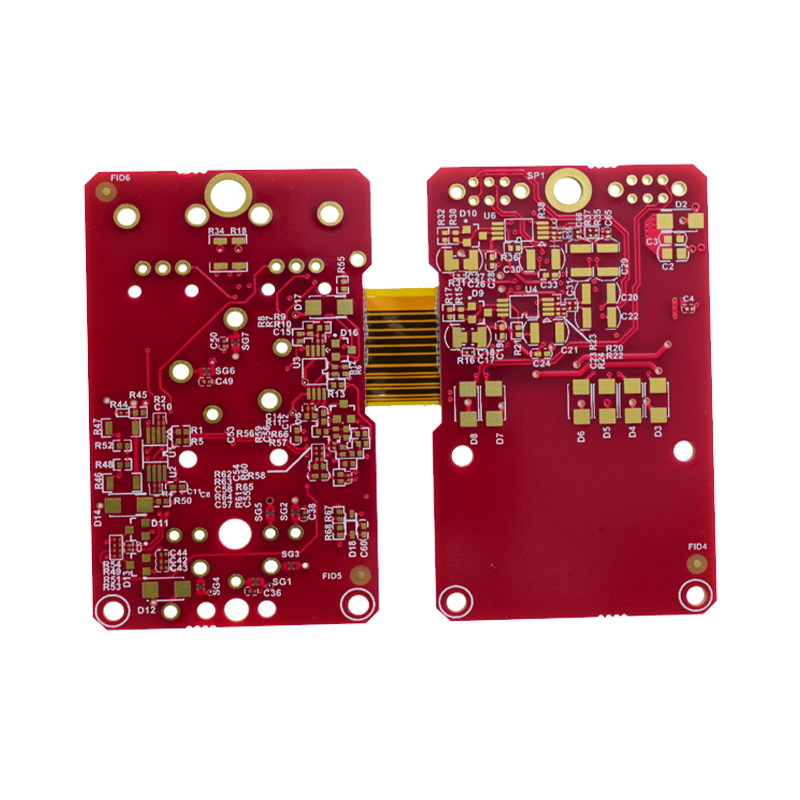

Flexible board uye rigid-flex board welding

Flexible uye akaomesesa-flex akadhindwa edunhu mabhodhi anopa kuchinjika uye kuita zvakasiyana-siyana mukugadzira, zvichiita kuti zvive zvakanaka kune zvikumbiro zvinoda bendability kana compact fomu zvinhu. Kutengesa marudzi aya emabhodhi edunhu kunoda hunyanzvi hwekuita kuti uve nechokwadi chekugara uye kuvimbika.

Unyanzvi hwaCapel mukutengesa flexible uye rigid-flex PCBsinova nechokwadi chekuti mapuranga aya anogona kumira kudzokororwa kukotama uye kuchengetedza kushanda kwawo. Nehunyanzvi hwekuita tekinoroji, Capel inowana majoini akavimbika ekutengesa kunyangwe munzvimbo dzakasimba dzinoda kuchinjika.

3. Capel's advanced process technology

Capel yakazvipira kuramba iri pamberi peindastiri nekudyara mumidziyo yemazuva ano uye maitiro matsva. Yavo yepamberi process tekinoroji inovagonesa kupa yekucheka-kumucheto mhinduro kune yakaoma welding zvinodiwa.

Nekubatanidza midziyo yekusodha yepamberi senge otomatiki yekuisa muchina uye maovheni ekudzoreredza ane hunyanzvi uye mainjiniya, Capel inogara ichiburitsa zvemhando yepamusoro solder. Kuzvipira kwavo mukurongeka uye hunyanzvi hunovaisa parutivi muindasitiri.

Muchidimbu

Iri gwara rakazara rinopa kunzwisisa kwakadzama kwePCB solder maitiro uye matekiniki. Kubva pachinyakare-chete-padivi uye maviri-mativi solder kune epamberi matekinoroji akadai seHDI PCB solder uye inochinjika PCB solder, hunyanzvi hweCapel hunopenya kuburikidza.

Nemakore gumi nemashanu echiitiko uye kuzvipira kune advanced process tekinoroji, Capel ishamwari yakavimbika kune ese PCB soldering zvinodiwa. Bata Capel nhasi kune yakavimbika, yemhando yepamusoro PCB solder mhinduro, inotsigirwa nehunyanzvi hwavo uye tekinoroji yakaratidza.

Nguva yekutumira: Nov-07-2023

Back