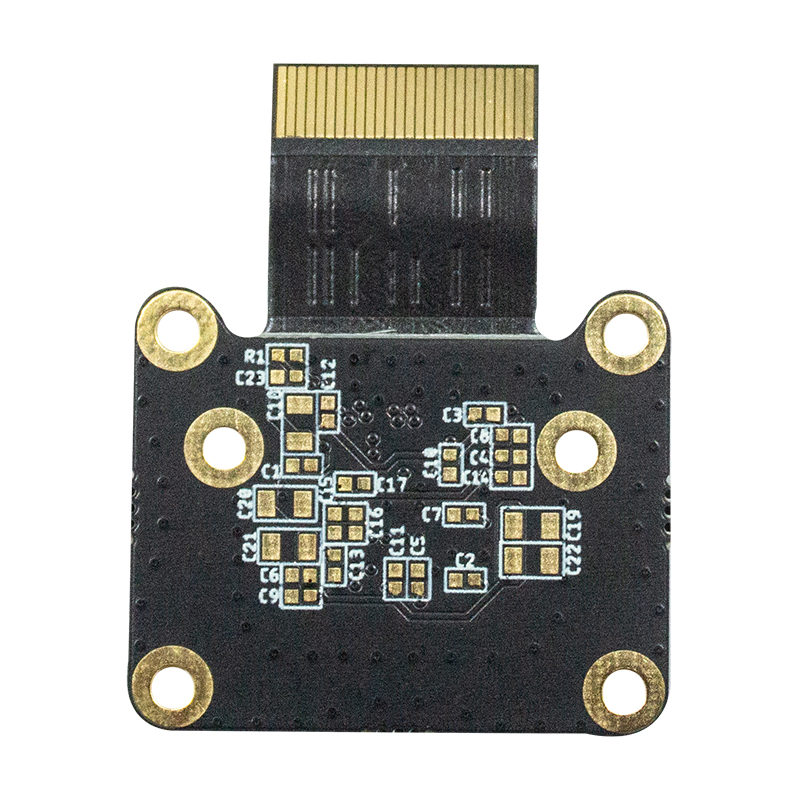

PCB (Printed Circuit Board) chinhu chakakosha muzvigadzirwa zvemagetsi zvemazuva ano, zvichigonesa kubatana nekushanda kwezvinhu zvakasiyana-siyana zvemagetsi. Iyo PCB yekugadzira maitiro inosanganisira akati wandei akakosha matanho, imwe yacho kuisa mhangura pane substrate. Ichi chinyorwa tichatarisa nzira dzekuisa mhangura paPCB substrates panguva yekugadzira, uye tigoongorora nzira dzakasiyana dzinoshandiswa, senge electroless copper plating uye electroplating.

1.Electroless copper plating: tsananguro, makemikari maitiro, zvakanakira, zvisingabatsiri uye nzvimbo dzekushandisa.

Kuti unzwisise kuti chii chinonzi electroless copper plating, zvakakosha kuti unzwisise kuti inoshanda sei. Kusiyana neelectrodeposition, iyo inovimba nemagetsi ikozvino yekuisa simbi, electroless copper plating ndeye autophoretic process. Inosanganisira kudzorwa kwekemikari kuderedzwa kwecopper ions pane substrate, zvichikonzera yunifomu uye conformal copper layer.

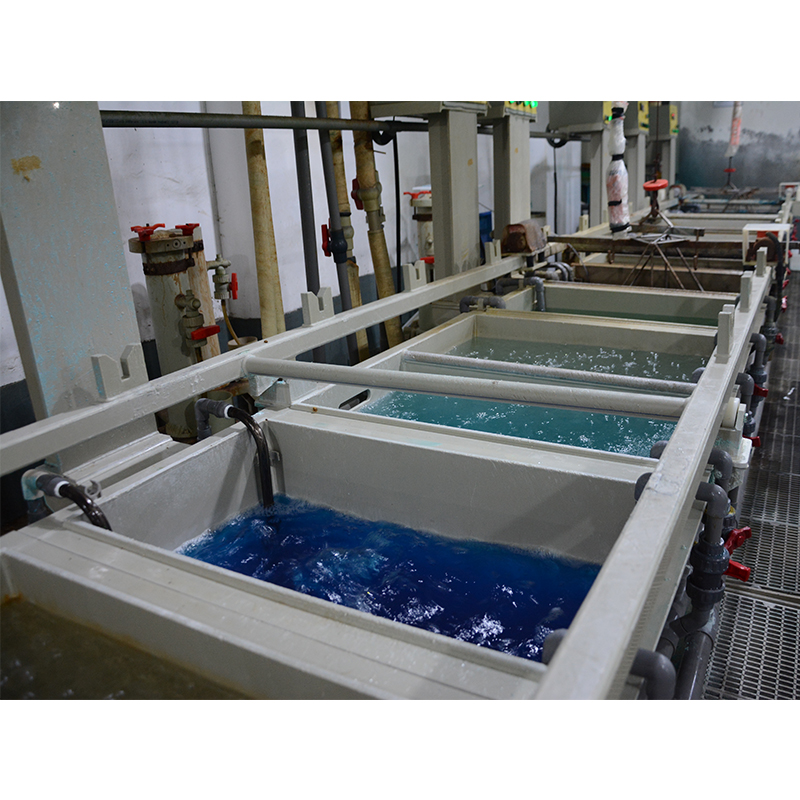

Chenesa substrate:Nyatsochenesa pasi pasi kuti ubvise chero tsvina kana okisidhi inogona kudzivirira kunamatira. Activation: Iyo activation solution ine yakakosha simbi inokonzeresa senge palladium kana platinamu inoshandiswa kutanga iyo electroplating process. Iyi mhinduro inofambisa kuiswa kwemhangura pane substrate.

Nyura mumushonga weplating:Nyura iyo activated substrate mune electroless copper plating mhinduro. Mhinduro yeplating ine maion emhangura, ekudzikisa maajenti uye akasiyana ekuwedzera anodzora maitiro ekuisa.

Electroplating process:Iyo inodzikisa mumiriri mune electroplating mhinduro yemakemikari inoderedza ayoni emhangura kuita esimbi maatomu emhangura. Aya maatomu anobva abatana nepamusoro penzvimbo yakabatidzwa, achigadzira mhangura inoenderera uye yakafanana.

Sukurudza uye woomesa:Kana iyo inodiwa yemhangura ukobvu yaitwa, iyo substrate inobviswa kubva muplating tangi uye yosukurudzwa zvakakwana kubvisa chero makemikari asara. Pukuta substrate yakapfava usati waenderera mberi nekugadzirisa. Chemical copper plating process Iyo kemikari ye electroless copper plating inosanganisira redox reaction pakati pemaoni emhangura uye ekudzikisa. Matanho akakosha mukuita izvi anosanganisira: Activation: Kushandiswa kweanoble metal catalysts senge palladium kana platinamu kumutsa substrate pamusoro. Iyo catalyst inopa nzvimbo dzinodiwa dzemakemikari bonding yecopper ions.

Reducing agent:Iyo inoderedza mumiriri mune yeplating mhinduro (kazhinji formaldehyde kana sodium hypophosphite) inotanga maitiro ekuderedza. Reagents izvi donate maerekitironi kuti ayoni mhangura, kuvashandura kuva esimbi maatomu emhangura.

Autocatalytic reaction:Maatomu emhangura anogadzirwa neatomu yekudzikisa anoita necatalyst iri pamusoro pe substrate kuti iite yunifomu yemhangura layer. Mhedzisiro yacho inoenderera pasina kudiwa kweiyo yekunze inoshandiswa ikozvino, zvichiita kuti ive "electroless plating."

Deposition rate control:Iko kuumbwa uye kusungirirwa kweiyo plating mhinduro, pamwe nemaitiro ekuita senge tembiricha uye pH, anodzorwa nekuchenjera kuti ave nechokwadi chekuti deposition rate inodzorwa uye yakafanana.

Zvakanakira zve electroless copper plating Uniformity:Electroless copper plating ine yakanakisa kufanana, kuve nechokwadi cheunifomu ukobvu mumhando dzakaoma uye nzvimbo dzakadzoserwa. Conformal Coating: Ichi chiitiko chinopa conformal coating inonamatira zvakanaka kune geometrically irregular substrates sePCBs. Kunamatira kwakanaka: Electroless copper plating ine kunamatira kwakasimba kune dzakasiyana siyana substrate zvinhu, zvinosanganisira mapurasitiki, ceramics nesimbi. Kusarudzika Plating: Electroless copper plating inogona kusarudza kuisa mhangura munzvimbo dzakatarwa dze substrate uchishandisa masking matekiniki. Mutengo Wakaderera: Uchienzaniswa nedzimwe nzira, electroless copper plating isarudzo inodhura yekuisa mhangura pane substrate.

Kuipa kwe electroless copper plating Inononoka deposition rate:Kuenzaniswa nemaitiro e electroplating, electroless copper plating kazhinji ine inononoka deposition rate, iyo inogona kurebesa iyo yakazara electroplating process process. Ukobvu hushoma: Electroless copper plating inowanzokodzera kuisa zvidimbu zvitete zvemhangura uye nekudaro haina kunyanyokodzera maapplication anoda kukora. Kuoma: Iyo nzira inoda kungwarira kutonga kweakasiyana ma paramita, anosanganisira tembiricha, pH uye makemikari kudzika, zvichiita kuti zvive zvakaoma kuita kupfuura dzimwe nzira dze electroplating. Waste Management: Kuraswa kwemarara ekuisa zvigadziriso zvine chepfu inorema simbi kunogona kuunza matambudziko ezvakatipoteredza uye kunoda kungwarira kubata.

Nzvimbo dzekushandisa dze electroless copper plating PCB Manufacturing:Electroless copper plating inoshandiswa zvakanyanya mukugadzirwa kweakadhindwa edunhu mabhodhi (PCBs) kugadzira maitiro ekuitisa uye akaputirwa nemakomba. Semiconductor indasitiri: Inoita basa rakakosha mukugadzira semiconductor zvishandiso senge chip inotakura uye inotungamira mafuremu. Maindasitiri emotokari uye aerospace: Electroless copper plating inoshandiswa kugadzira magetsi ekubatanidza, switch uye yakakwirira-inoshanda zvemagetsi zvikamu. Decorative and Functional Coatings: Electroless copper plating inogona kushandiswa kugadzira kushongedza kunopedzisa pane akasiyana substrates, pamwe nekudzivirira ngura uye kuvandudzwa kwemagetsi conductivity.

2.Copper plating paPCB substrate

Copper plating paPCB substrates inhanho yakakosha mune yakadhindwa redunhu bhodhi (PCB) kugadzira maitiro. Mhangura inowanzoshandiswa sechinhu che electroplating nekuda kwekunaka kwayo kwemagetsi conductivity uye kunamatira kwakanaka kune substrate. Iyo copper plating process inosanganisira kuisa nhete yemhangura pamusoro pePCB kugadzira nzira dzinofambisa dzemagetsi masaini.

Iyo mhangura yekuisa maitiro paPCB substrates kazhinji inosanganisira anotevera matanho: Surface Kugadzirira:

Nyatsochenesa iyo PCB substrate kubvisa chero tsvina, okisidhi kana tsvina inogona kutadzisa kunamatira uye kukanganisa kunaka kweplating.

Kugadzirira kweElectrolyte:

Gadzirira mhinduro ye electrolyte ine copper sulfate sechitubu checopper ions. Iyo electrolyte zvakare ine zvinowedzerwa zvinodzora maitiro ekuputira, senge maajenti ekuyera, anopenya, uye pH anogadzirisa.

Electrodeposition:

Nyura iyo yakagadzirirwa PCB substrate mumhinduro ye electrolyte uye shandisa yakananga ikozvino. Iyo PCB inoshanda secathode yekubatanidza, nepo anode yemhangura iripowo mune mhinduro. Ikozvino inoita kuti maion emhangura ari mu electrolyte aderedzwe uye aiswe pamusoro pePCB.

Kudzora kweplating parameters:

Yakasiyana-siyana ma paramita anodzorwa nekuchenjerera panguva yeplating process, kusanganisira yazvino density, tembiricha, pH, inomutsa uye plating nguva. Aya ma paramita anobatsira kuve nechokwadi chekuiswa kwakafanana, kunamatira, uye ukobvu hunodiwa hwemhangura layer.

Post-plating treatment:

Kana hukobvu hwemhangura hunodiwa hwasvikwa, PCB inobviswa mubhavhu yekuputira uye yosukurudzwa kubvisa chero yasara electrolyte mhinduro. Kuwedzera kurapwa kwemashure, sekunge kucheneswa kwepasi uye passivation, kunogona kuitwa kuvandudza kunaka uye kugadzikana kwemhangura yeplating layer.

Zvinhu zvinokanganisa kunaka kwe electroplating:

Kugadzirira Kwepamusoro:

Kucheneswa kwakakodzera uye kugadzirira kwePCB pamusoro kwakakosha kuti ubvise chero zvinosvibisa kana oxide layer uye kuve nechokwadi chekunamatira kwakanaka kwemhangura plating. Plating solution kuumbwa:

Iko kuumbwa kwemhinduro ye electrolyte, kusanganisira kusanganiswa kwemhangura sulfate uye zvinowedzera, zvinokanganisa kunaka kwekuputira. Iyo yekugezera yekugezesa inoumbwa inofanira kunyatsodzorwa kuti iwane yainoda plating maitiro.

Plating Parameters:

Kudzora plating paramita senge yazvino density, tembiricha, pH, inosimudzira uye yekuisa nguva inodiwa kuti uve nechokwadi chekuisa yunifomu, kunamatira uye ukobvu hwemhangura layer.

Substrate zvinhu:

Rudzi uye mhando yePCB substrate zvinhu zvinokanganisa kunamatira uye mhando yemhangura yekuisa. Yakasiyana substrate zvinhu zvingada kugadziridzwa kune plating maitiro kuti uwane mhedzisiro.

Surface roughness:

Iko kushata kwepamusoro kwePCB substrate kuchakanganisa kunamatira uye kunaka kwemhangura yeplating layer. Kugadzirira kwepamusoro kwepamusoro uye kutonga kwemaparamendi ekuisa kunobatsira kuderedza matambudziko ane chekuita nekukasharara

Zvakanakira zvePCB substrate copper plating:

Yakanakisa magetsi conductivity:

Mhangura inozivikanwa nekukwira kwayo kwemagetsi conductivity, zvichiita kuti ive sarudzo yakanaka yePCB yekuisa zvinhu. Izvi zvinovimbisa kushanda kwakanaka uye kwakavimbika kwezviratidzo zvemagetsi. Yakanakisa adhesion:

Mhangura inoratidzira kunamatira kwakanakisa kune dzakasiyana siyana substrates, kuve nechokwadi chakasimba uye chinogara kwenguva refu chisungo pakati pekupfeka uye substrate.

Corrosion Resistance:

Mhangura ine yakanaka corrosion resistance, inodzivirira zviri pasi pePCB zvikamu uye nekuona kuvimbika kwenguva refu. Solderability: Copper plating inopa nzvimbo inokodzera solder, zvichiita kuti zvive nyore kubatanidza zvinhu zvemagetsi panguva yegungano.

Enhanced heat dissipation:

Mhangura yakanaka yekupisa conductor, inogonesa kupisa kupisa kwePCBs. Izvi zvinonyanya kukosha kune yakakwirira simba zvikumbiro.

Kukanganisa uye matambudziko emhangura electroplating:

Kudzora ukobvu:

Kuwana kunyatso kudzora pamusoro pemhangura layer ukobvu kunogona kunetsa, kunyanya munzvimbo dzakaoma kana nzvimbo dzakasimba paPCB. Uniformity: Kuve nechokwadi chekuisa yunifomu yemhangura pamusoro pese pese pePCB, kusanganisira nzvimbo dzakadzoserwa uye maficha akanaka, zvinogona kuoma.

Mutengo:

Electroplating mhangura inogona kudhura zvakanyanya kana ichienzaniswa nedzimwe nzira dze electroplating nekuda kwemutengo weplating tank makemikari, zvishandiso, uye kugadzirisa.

Waste Management:

Kuraswa kwemhinduro dzeplating dzakashandiswa uye kurapwa kwemvura yetsvina ine ioni dzemhangura nemamwe makemikari kunoda maitiro akakodzera ekugadzirisa tsvina kuti kuderedze kukanganisa kwezvakatipoteredza.

Process Complexity:

Electroplating mhangura inosanganisira akati wandei ma paramita anoda kungwarira kudzora, inoda ruzivo rwehunyanzvi uye akaomarara ekuseta.

3.Kuenzanisa pakati pe electroless copper plating uye electroplating

Performance uye mhando dzakasiyana:

Pane misiyano yakati wandei mukuita uye mhando pakati pe electroless copper plating uye electroplating mune zvinotevera zvinhu:

Electroless copper plating ikemikari deposition process isingade simba rekunze, nepo electroplating inosanganisira kushandisa yakananga ikozvino kuisa dura remhangura. Iyi misiyano mumagadzirirwo ekuisa inogona kutungamirira kune kusiyana kwehutano hwekuputira.

Electroless copper plating kazhinji inopa yakawedzera yunifomu yekuisa pamusoro pese substrate pamusoro, kusanganisira nzvimbo dzakadzoserwa uye yakanaka maficha. Izvi zvinodaro nekuti plating inoitika zvakaenzana pamativi ese zvisinei nekwairi kuita. Electroplating, kune rumwe rutivi, inogona kunetseka kuwana yunifomu deposition munzvimbo dzakaoma kana dzakaoma-kusvika.

Electroless copper plating inogona kuwana yakakwira aspect ratio (reshiyo yehurefu hwechimiro kusvika kuhupamhi) pane electroplating. Izvi zvinoita kuti ive yakakodzera kune maapplication anoda yakakwira aspect ratio zvivakwa, senge kuburikidza-maburi muPCBs.

Electroless copper plating inowanzo gadzira nzvimbo yakatsetseka, yakati sandara pane electroplating.

Electroplating dzimwe nguva inogona kukonzera kusaenzana, kushata kana kusina mari nekuda kwekuchinja kwehuwandu hwazvino uye mamiriro ekugezera. Hunhu hwechisungo pakati pemhangura plating layer uye substrate inogona kusiyana pakati pe electroless copper plating uye electroplating.

Electroless copper plating inowanzopa kunamira kuri nani nekuda kwekemikari yekubatanidza nzira ye electroless mhangura kune substrate. Plating inotsamira pamakanika uye electrochemical bonding, izvo zvinogona kukonzeresa kushaya simba zvisungo mune dzimwe nguva.

Kuenzanisa Mutengo:

Chemical Deposition vs. Electroplating: Kana uchienzanisa mutengo we electroless copper plating uye electroplating, zvinhu zvakati wandei zvinofanirwa kutariswa:

Mutengo wemakemikari:

Electroless copper plating kazhinji inoda makemikari anodhura kana achienzaniswa ne electroplating. Iwo makemikari anoshandiswa mu electroless plating, senge ekudzikisa maajenti uye stabilizer, anowanzo hunyanzvi uye anodhura.

Mari yemidziyo:

Plating units inoda midziyo yakaoma uye inodhura, kusanganisira magetsi, rectifiers uye anode. Electroless copper plating masisitimu ari nyore uye anoda mashoma ezvikamu.

Mari yekuchengetedza:

Plating midziyo inogona kuda nguva nenguva kugadzirisa, calibration, uye kutsiva anode kana zvimwe zvikamu. Electroless copper plating masisitimu kazhinji inoda kushomeka kugadziridzwa uye ine yakaderera mari yekugadziridza.

Kushandiswa kwePting Chemicals:

Plating masisitimu anodya makemikari eplating pamwero wepamusoro nekuda kwekushandiswa kwemagetsi ikozvino. Iko kushandiswa kwemakemikari kwe electroless copper plating system kwakadzikira nekuti iyo electroplating reaction inoitika kuburikidza nekemikari reaction.

Mari yekudzora tsvina:

Electroplating inogadzira imwe tsvina, kusanganisira yakapedzwa yekugezera yekugezera uye kugezesa mvura yakasvibiswa nesimbi ions, inoda kurapwa kwakakodzera uye kuraswa. Izvi zvinowedzera mutengo wakazara weplating. Electroless copper plating inoburitsa marara mashoma nekuti haivimbi nekuenderera mberi kwekupihwa kwesimbi maion mubhati replating.

Zvinonetsa uye Zvinetso zveElectroplating uye Chemical Deposition:

Electroplating inoda kungwarira kutonga kweakasiyana ma paramita akadai seyazvino density, tembiricha, pH, nguva yeplating uye kumhanyisa. Kuwana yunifomu yekuisa uye yaunoda plating hunhu inogona kuve yakaoma, kunyanya mune yakaoma geometries kana yakaderera ikozvino nzvimbo. Kukwidziridzwa kwekuumbwa kwekugezera kwekugezera uye paramita kungangoda kuyedza kwakawanda uye hunyanzvi.

Electroless copper plating inodawo kutonga kwema paramita senge kudzikisa mumiriri, tembiricha, pH uye nguva yeplating. Nekudaro, kutonga kweaya ma paramita kazhinji haakoshese mu electroless plating pane mu electroplating. Kuzadzikisa zvivakwa zveplating, senge deposition rate, ukobvu, uye kunamatira, zvinogona kunge zvichiri kuda optimization uye yekutarisa maitiro eplating.

Mu electroplating uye electroless copper plating, kunamatira kune akasiyana substrate zvinhu zvinogona kuve dambudziko rinowanzoitika. Pre-kurapwa kwe substrate pamusoro kubvisa zvinosvibisa uye kukurudzira kunamatira kwakakosha kune ese ari maviri maitiro.

Kugadzirisa uye kugadzirisa dambudziko mu electroplating kana electroless copper plating inoda ruzivo rwakanyanya uye ruzivo. Nyaya dzakaita sekukasharara, kusaenzana kwekuisa, voids, kubhubhura, kana kusanamatira zvakanaka zvinogona kuitika mukati memaitiro ese ari maviri, uye kuziva chikonzero uye kutora matanho ekugadzirisa zvinogona kunetsa.

Chikamu chekushandiswa kwe tekinoroji yega yega:

Electroplating inowanzoshandiswa mumaindasitiri akasiyana siyana anosanganisira zvemagetsi, zvemotokari, aerospace uye zvishongo zvinoda kunyatso kudzora ukobvu, kupedzisa kwemhando yepamusoro uye zvinhu zvinodikanwa zvemuviri. Inoshandiswa zvakanyanya mukushongedza kupedzisa, simbi yekupfeka, corrosion kudzivirira uye yemagetsi chikamu chekugadzira.

Electroless copper plating inonyanya kushandiswa muindasitiri yemagetsi, kunyanya mukugadzira akadhindwa edunhu mabhodhi (PCBs). Inoshandiswa kugadzira nzira dzekufambisa, nzvimbo dzinotengeswa uye kupera kwepamusoro paPCBs. Electroless copper plating inoshandiswawo kugadzira simbi mapurasitiki, kugadzira mhangura yekubatanidza mune semiconductor mapakeji, uye zvimwe zvinoshandiswa zvinoda yunifomu uye conformal mhangura deposition.

4.Copper deposition maitiro emhando dzakasiyana dzePCB

Single-sided PCB:

Mune imwe-sided PCBs, mhangura deposition inowanzoitwa uchishandisa subtractive process. Iyo substrate inowanzogadzirwa neasina-conductive zvinhu zvakadai seFR-4 kana phenolic resin, yakafukidzwa nehutete hwakatsetseka hwemhangura kune rumwe rutivi. Iyo mhangura yemhangura inoshanda senzira yekufambisa yedunhu. Iyo nzira inotanga nekuchenesa uye kugadzirira kweiyo substrate pamusoro kuti ive nechokwadi chekunamatira kwakanaka. Inotevera iko kushandiswa kweiyo yakatetepa layer ye photoresist zvinhu, iyo inovhenekerwa kune UV mwenje kuburikidza ne photomask kutsanangura dunhu pateni. Nzvimbo dzakavhurika dzekupikiswa dzinonyungudika uye dzinobva dzashambidzwa, dzichiisa pachena pasi pemhangura layer. Nzvimbo dzakafumurwa dzemhangura dzinobva dzadzikwa uchishandisa etchant senge ferric chloride kana ammonium persulfate. Iyo etchant inosarudza inobvisa mhangura yakafumurwa, ichisiya inodiwa yedunhu pateni. Iyo yakasara inopikisa inobva yabviswa, ichisiya mitsetse yemhangura. Mushure mekuita etching, iyo PCB inogona kuita mamwe matanho ekugadzirira epamusoro senge solder mask, kudhinda kwescreen, uye kushandiswa kwezvidziviriro zvitubu kuti ive nechokwadi chekusimba uye kuchengetedzwa kubva kune zvakatipoteredza zvinhu.

PCB ine mativi maviri:

PCB ine mbiri-mativi PCB ine mhangura yemhangura pamativi ese e substrate. Maitiro ekuisa mhangura kumativi ese anosanganisira mamwe matanho achienzaniswa neamwe-sided PCBs. Maitiro acho akafanana ne-single-sided PCB, kutanga nekuchenesa nekugadzirira kwe substrate pamusoro. Chigadziko chemhangura chinozoiswa pamativi ese e substrate uchishandisa electroless copper plating kana electroplating. Electroplating inowanzo shandiswa nhanho iyi nekuti inobvumidza zvirinani kutonga pamusoro pekukora uye kunaka kwemhangura layer. Mushure mekunge mhangura yemhangura yaiswa, mativi ese ari maviri akaputirwa nephotoresist uye dunhu redunhu rinotsanangurwa kuburikidza nekuratidzwa uye nhanho dzekusimudzira dzakafanana nedziya dzePCB dzine divi rimwe chete. Nzvimbo dzakafumurwa dzemhangura dzinobva dzadzikwa kuti dziite matunhu anodiwa. Mushure mekucheka, kuramba kunobviswa uye PCB inopinda nemamwe matanho ekugadzirisa senge solder mask application uye kurapwa kwepamusoro kupedzisa kugadzirwa kwePCB ine mativi maviri.

Multilayer PCB:

Multilayer PCBs akagadzirwa neakawanda akaturikidzana emhangura uye insulating zvinhu zvakaturikidzana pamusoro peumwe neumwe. Copper deposition mu multilayer PCBs inosanganisira akawanda matanho ekugadzira nzira dzekufambisa pakati pematanho. Maitiro acho anotanga nekugadzira iwo ega ega PCB akaturikidzana, akafanana neamwe divi kana maviri-mativi maPCB. Imwe neimwe nhanho inogadzirirwa uye photoresist inoshandiswa kutsanangura dunhu pateni, inoteverwa nemhangura deposition kuburikidza ne electroplating kana electroless copper plating. Mushure mekuisa, imwe neimwe layer yakaputirwa ne insulating material (kazhinji epoxy-based prepreg kana resin) yobva yaiswa pamwechete. Iwo maturu anorongeka uchishandisa kudhirowa chaiko uye nzira dzekunyoresa dzemakanika kuti ive nechokwadi chekubatana pakati pematanho. Kamwe akaturikidzana vari akaturikidzana, vias anogadzirwa nokuchera makomba kuburikidza akaturikidzana panguva chaiyo pfungwa apo interconnects zvinodiwa. The vias zvino akaputirwa nemhangura vachishandisa electroplating kana electroless mhangura plating kugadzira magetsi kubatana pakati akaturikidzana. Maitiro acho anoenderera mberi nekudzokorora dhizaini, kudhirowa, uye matanho emhangura yemhangura kudzamara ese anodiwa akaturikidzana uye anobatana agadzirwa. Nhanho yekupedzisira inosanganisira kurapwa kwepamusoro, solder mask application uye mamwe maitiro ekupedzisa kupedzisa kugadzirwa kweakawanda-layer PCB.

High Density Interconnect (HDI) PCB:

HDI PCB ndeye-multi-layer PCB yakagadzirirwa kugarisa yakakwira density wedunhu uye diki fomu chinhu. Kuiswa kwemhangura muHDI PCBs kunosanganisira matekiniki epamusoro ekugonesa maficha akanaka uye akasimba dhizaini. Maitiro acho anotanga nekugadzira akawanda ma-ultra-thin layers, anowanzonzi core material. Aya macores ane foil yemhangura yakatetepa padivi rega rega uye inogadzirwa kubva kune yakakwirira-performance resin zvinhu zvakaita seBT (Bismaleimide Triazine) kana PTFE (Polytetrafluoroethylene). Iwo epakati zvinhu akaturikidzana uye laminated pamwe chete kugadzira akawanda-layer chimiro. Laser drilling inobva yashandiswa kugadzira microvias, ari maburi madiki anobatanidza ma layer. Microvias inowanzozadzwa nezvinhu zvinoitisa semhangura kana conductive epoxy. Mushure mekunge ma microvias aumbwa, mamwe machira akaiswa uye akaiswa laminated. Iyo inoteedzana lamination uye laser drilling process inodzokororwa kugadzira akawanda akaturikidzana akaturikidzana ane microvia anobatana. Pakupedzisira, mhangura inoiswa pamusoro peHDI PCB ichishandisa matekiniki akadai se electroplating kana electroless copper plating. Tichifunga nezveakanaka maficha uye yakakwirira density yedunhu reHDI PCBs, deposition inodzorwa nekuchenjera kuti iwane inodiwa yemhangura layer ukobvu uye mhando. Iyo nzira inopera nekuwedzera kwepamusoro kurapwa uye kupedzisa maitiro ekupedzisa HDI PCB kugadzira, iyo inogona kusanganisira solder mask application, pamusoro pekupedzisira application uye kuyedza.

Flexible circuit board:

Flexible PCBs, inozivikanwawo semasekete anochinjika, akagadzirirwa kuchinjika uye anokwanisa kuchinjika kune akasiyana maumbirwo kana kubhenda panguva yekushanda. Kuiswa kwemhangura mumaPCB anochinjika kunosanganisira maitiro chaiwo anosangana nekuchinjika uye kusimba zvinodiwa. Flexible PCBs inogona kuva imwe-side, kaviri-mativi, kana akawanda-layered, uye mhangura deposition matekiniki anosiyana zvichienderana nedhizaini zvinodiwa. Kazhinji kutaura, maPCB anochinjika anoshandisa foil yakatetepa yemhangura kana ichienzaniswa neyakaomarara maPCB kuti uwane kuchinjika. Kune imwechete-sided flexible PCBs, maitiro acho akafanana ne-single-sided rigid PCBs, kureva, chidimbu chitete chemhangura chinoiswa pa-flexible substrate uchishandisa electroless copper plating, electroplating, kana musanganiswa wezvose. Kune maviri-mativi kana akawanda-layer anochinjika maPCB, maitiro anosanganisira kuisa mhangura pamativi ese eiyo inochinjika substrate uchishandisa electroless copper plating kana electroplating. Tichifunga nezve yakasarudzika mechaniki zvivakwa zvezvinhu zvinochinjika, deposition inodzorwa nekuchenjera kuti ive nechokwadi chekunamatira uye kuchinjika. Mushure mekuiswa kwemhangura, iyo PCB inoshanduka inoenda kuburikidza nekuwedzera maitiro akadai sekuchera, dunhu patani, uye pamusoro pematanho ekurapa kugadzira inodiwa wedunhu uye kupedzisa kugadzirwa kweiyo inoshanduka PCB.

5.Advances uye Innovations muCopper Deposition paPCBs

Kuvandudza Tekinoroji Yezvino: Kwemakore, tekinoroji yekuisa mhangura paPCB yakaramba ichishanduka nekuvandudza, zvichikonzera kuwedzera kwekuita uye kuvimbika. Zvimwe zvezvino kuvandudzwa tekinoroji muPCB copper deposition zvinosanganisira:

Advanced plating tekinoroji:

Tekinoroji nyowani dzeplating, senge pulse plating uye reverse pulse plating, dzakagadziridzwa kuti dziwane yakakwenenzverwa uye yakawanda yunifomu yekuisa mhangura. Aya matekinoroji anobatsira kukunda matambudziko akadai sekuoma kwepasi, saizi yezviyo uye kugovera ukobvu kuvandudza kushanda kwemagetsi.

Direct metallization:

Kugadzirwa kwechinyakare kwePCB kunosanganisira matanho akati wandei ekugadzira maconductive nzira, kusanganisira kuisa mhodzi pamberi pemhangura yekuputira. Kuvandudzwa kwemaitiro ekugadzira simbi yakananga kunobvisa kudiwa kwembeu yakaparadzana, nekudaro kurerutsa maitiro ekugadzira, kuderedza mutengo uye kuvandudza kuvimbika.

Microvia tekinoroji:

Microvias maburi madiki anobatanidza zvidimbu zvakasiyana mune multilayer PCB. Kufambira mberi mune tekinoroji yemicrovia senge laser drilling uye plasma etching inogonesa kugadzirwa kwezvidiki, zvakanyatsojeka microvias, zvichigonesa yakakwirira density maseketi uye inovandudza chiratidzo chekuvimbika. Surface Pedzisa Innovation: Kupedzisa kwepamusoro kwakakosha kuchengetedza maronda emhangura kubva kune oxidation uye kupa solderability. Kuvandudzwa kwehunyanzvi hwekurapa kwepamusoro, senge Immersion Silver (ImAg), Organic Solderability Preservative (OSP), uye Electroless Nickel Immersion Gold (ENIG), inopa kuchengetedzwa kurinani kwekuora, kunatsiridza solderability, uye kuwedzera kuvimbika kwese.

Nanotechnology uye Copper Deposition: Nanotechnology inoita basa rakakosha mukufambisira mberi kwePCB copper deposition. Zvimwe zvekushandisa nanotechnology mumhangura deposition zvinosanganisira:

Nanoparticle-based plating:

Mhangura nanoparticles inogona kuverengerwa muplating mhinduro yekusimudzira maitiro ekuisa. Aya nanoparticles anobatsira kuvandudza kunamatira kwemhangura, saizi yezviyo uye kugovera, nekudaro kuderedza resistivity uye kuwedzera kushanda kwemagetsi.

Nanostructured Conductive Materials:

Nanostructured zvinhu, senge kabhoni nanotubes uye graphene, zvinogona kubatanidzwa muPCB substrates kana kushanda se conductive fillers panguva yekuisa. Zvishandiso izvi zvine kukwirira kwemagetsi conductivity, simba remagetsi uye zvivakwa zvinopisa, nekudaro zvinovandudza kuita kwese kwePCB.

Nanocoating:

Nanocoating inogona kuiswa kuPCB pamusoro kuti ivandudze kutsvedzerera kwepasi, solderability uye kudzivirira ngura. Aya mabhanhire anowanzo gadzirwa kubva kune nanocomposites anopa kuchengetedzwa kuri nani kubva kune zvakatipoteredza zvinhu uye kuwedzera hupenyu hwePCB.

Nanoscale inobatanidza:Nanoscale interconnects, senge nanowires uye nanorods, iri kuongororwa kuti igonese yakakwirira density maseketi muPCBs. Aya maumbirwo anofambisa kubatanidzwa kwemamwe maseketi munzvimbo diki, achibvumira kuvandudzwa kwezvidiki, zvakanyanya compact midziyo yemagetsi.

Zvinetso uye mafambiro emangwana: Pasinei nekufambira mberi kwakakosha, matambudziko akati wandei nemikana yasara yekuwedzera kuvandudza kuiswa kwemhangura paPCB. Mamwe matambudziko akakosha uye mafambiro emangwana anosanganisira:

Mhangura Inozadza mune Yakakwirira Aspect Ratio Zvimiro:

Yakakwira chikamu cheyero zvimiro senge vias kana microvias zvinopa matambudziko mukuwana yunifomu uye yakavimbika mhangura yekuzadza. Kumwe kutsvagurudza kunodiwa kuvandudza nzira dzepamusoro dzekuputira kana dzimwe nzira dzekuzadza kuti ukunde matambudziko aya uye kuve nechokwadi chekuisa mhangura mune yakakwira chikamu ratio zvimiro.

Kuderedza Copper Trace Width:

Sezvo midziyo yemagetsi inova diki uye yakawanda compact, kudiwa kwehutete hwemhangura kunoramba kuchikura. Dambudziko nderekuwana yunifomu uye yakavimbika mhangura deposition mukati meaya matete akateedzera, kuve nechokwadi chakaenderana kushanda kwemagetsi uye kuvimbika.

Alternative conductor materials:

Nepo mhangura iri iyo inonyanya kushandiswa kondakita zvinhu, zvimwe zvinhu zvakaita sesirivheri, aruminiyamu, uye kabhoni nanotubes zviri kuongororwa nekuda kwezvakasiyana zvivakwa uye mabhenefiti ekuita. Tsvagiridzo yeramangwana inogona kutarisisa mukugadzira dhizaini nzira dzeaya mamwe ma conductor zvinhu kuti akunde matambudziko akadai sekunamatira, resistivity, uye kuenderana nePCB kugadzira maitiro. ZvakatipoteredzaHushamwari Maitiro:

Iyo PCB indasitiri inogara ichishanda kune zvakatipoteredza hushamwari maitiro. Zviitiko zveramangwana zvinogona kutarisisa kudzikisa kana kubvisa kushandiswa kwemakemikari ane njodzi panguva yekuiswa kwemhangura, kugadzirisa mashandisirwo emagetsi, uye kuderedza kugadzirwa kwemarara kuderedza kukanganiswa kwezvakatipoteredza kwePCB kugadzira.

Yepamberi Simulation uye Modelling:

Simulation uye nzira dzekuenzanisira dzinobatsira kukwenenzvera nzira dzekuisa mhangura, kufanotaura maitiro ekuisa paramita, uye kugadzirisa huchokwadi uye kugona kwePCB kugadzira. Kufambira mberi kweramangwana kunogona kusanganisira kubatanidza maturusi epamberi uye maturusi ekuenzanisira mudhizaini nekugadzira maitiro kuitira kugonesa kutonga kuri nani uye kugadzirisa.

6.Quality Assurance uye Kudzora kweCopper Deposition yePCB Substrates

Kukosha kwekusimbiswa kwemhando: Kuvimbiswa kwemhando yakakosha muhurongwa hwekuisa mhangura nekuda kwezvikonzero zvinotevera:

Kuvimbika kweChigadzirwa:

Kuiswa kwemhangura paPCB kunoumba hwaro hwekubatanidza magetsi. Kuve nechokwadi chemhando yekuiswa kwemhangura kwakakosha kune yakavimbika uye inogara kwenguva refu kuita kwemagetsi zvigadzirwa. Kusadzika kwemhangura kuiswa kunogona kutungamira kune kukanganisa kwekubatanidza, chiratidzo chekumisikidza, uye kuderedzwa kwese kwePCB kuvimbika.

Kuita kwemagetsi:

Hunhu hwemhangura yemhangura hunokanganisa zvakananga mashandiro emagetsi ePCB. Uniform mhangura ukobvu uye kugovera, kutsetseka kwepamusoro kupedzisa, uye kunamatira kwakakodzera kwakakosha kuti uwane kushomeka kwekupokana, kufambisa kwechiratidzo kunoshanda, uye kushomeka kwechiratidzo kurasikirwa.

Deredza mari:

Kuvimbiswa kwehutano kunobatsira kuziva nekudzivirira matambudziko pakutanga kwekuita, kuderedza kudiwa kwekugadzirisa zvakare kana kubvisa maPCB asina kukwana. Izvi zvinogona kuchengetedza mari uye kuvandudza kushanda kwese kwekugadzira.

Mutengi Kugutsikana:

Kupa zvigadzirwa zvemhando yepamusoro kwakakosha kugutsikana kwevatengi uye kuvaka mukurumbira wakanaka muindasitiri. Vatengi vanotarisira zvigadzirwa zvinovimbika uye zvinogara kwenguva refu, uye vimbiso yemhando inoita kuti kuiswa kwemhangura kunosangana kana kudarika izvo zvinotarisirwa.

Kuedza uye nzira dzekuongorora dzekuisa mhangura: Dzakasiyana nzira dzekuyedza uye dzekuongorora dzinoshandiswa kuve nechokwadi chemhando yekuisa mhangura paPCB. Dzimwe nzira dzakajairika dzinosanganisira:

Visual Inspection:

Kuongorora kwekuona inzira yakakosha uye yakakosha yekuona zviripachena zvirema zvakaita sekukwenya, mazino kana kukwasharara. Ongororo iyi inogona kuitwa nemaoko kana nerubatsiro rweautomated optical inspection (AOI) system.

Microscopy:

Microscopy uchishandisa matekiniki akadai sekuongorora maelectron microscopy (SEM) anogona kupa ongororo yakadzama yemhangura deposition. Inogona kunyatsotarisa kupedzisa kwepamusoro, kunamatira uye kufanana kwemhangura yemhangura.

X-ray kuongorora:

X-ray yekuongorora matekiniki, akadai seX-ray fluorescence (XRF) uye X-ray diffraction (XRD), anoshandiswa kuyera kuumbwa, ukobvu uye kugovera kwemhangura deposits. Aya matekiniki anogona kuona kusvibiswa, yekutanga kuumbwa, uye kuona chero kusawirirana mukuiswa kwemhangura.

Kuedza Kwemagetsi:

Ita nzira dzekuyedza dzemagetsi, dzinosanganisira kuyerwa kuyerwa uye kuenderera mberi kwekuyedza, kuongorora mashandiro emagetsi emadhipoziti emhangura. Aya maedzo anobatsira kuve nechokwadi chekuti mhangura yemhangura ine inodiwa conductivity uye kuti hapana anovhura kana mapfupi mukati mePCB.

Peel Strength Test:

Iyo peel simba bvunzo inoyera simba rekubatanidza pakati pemhangura layer uye PCB substrate. Iyo inosarudza kana dhipoziti yemhangura ine simba rakakwana rechisungo kuti rimire zvakajairwa kubata uye PCB kugadzira maitiro.

Indasitiri mwero nemirau: Iyo PCB indasitiri inotevedzera akasiyana indasitiri zviyero uye mirau kuti ive nechokwadi chemhando yekuiswa kwemhangura. Mimwe mitemo yakakosha nemitemo inosanganisira:

IPC-4552:

Iyi chiyero inotsanangura zvinodikanwa zveelectroless nickel/immersion gold (ENIG) kurapwa kwepamusoro kunowanzo shandiswa paPCB. Iyo inotsanangura hushoma hwegoridhe ukobvu, nickel ukobvu uye pamusoro pemhando yeakavimbika uye anogara kwenguva refu ENIG epamusoro kurapwa.

IPC-A-600:

Iyo IPC-A-600 yakajairwa inopa PCB nhungamiro yekugamuchira, inosanganisira yemhangura yeplating yemhando zviyero, kuremara kwepasi uye mamwe maitiro emhando. Inoshanda sereferensi yekutarisa kwekuona uye maitiro ekugamuchirwa kwemhangura deposition paPCBs. RoHS Directive:

Iyo Restriction yeHazardous Substances (RoHS) dhairekitori inorambidza kushandiswa kwezvimwe zvinhu zvine ngozi muzvigadzirwa zvemagetsi, zvinosanganisira lead, mercury uye cadmium. Kutevedzera kuraira kweRoHS kunovimbisa kuti mhangura inoiswa paPCB haina zvinhu zvinokuvadza, zvichiita kuti ive yakachengeteka uye inoshamwaridzana nenharaunda.

ISO 9001:

ISO 9001 ndiyo chiyero chepasi rose chemhando yepamusoro masisitimu. Kumisikidza uye kuita ISO 9001-yakavakirwa hunhu manejimendi system inova nechokwadi chekuti maitiro akakodzera uye zvidzoreso zviripo kuti zvirambe zvichiunza zvigadzirwa zvinosangana nezvinodiwa nevatengi, kusanganisira mhando yemhangura yekuisa paPCB.

Kuderedza zvinowanzoitika uye kukanganisa: Mamwe matambudziko akajairika uye hurema hunogona kuitika panguva yekuiswa kwemhangura zvinosanganisira:

Kusakwana adhesion:

Kusakwana kunamatira kwemhangura yemhangura kune substrate kunogona kutungamirira kune delamination kana peeling. Kucheneswa kwakaringana kwepamusoro, kugadzirwa kwemagetsi, uye kurapa-kukurudzira kurapwa kunogona kubatsira kuderedza dambudziko iri.

Uneven Copper Ukobvu:

Ukobvu hwemhangura husina kuenzana hunogona kukonzera kusagadzikana conductivity uye kukanganisa kutapurirana kwechiratidzo. Kugadzirisa maparamendi ekuisa, kushandisa pulse kana reverse pulse plating uye kuve nechokwadi kuti kugwinya kwakakodzera kunogona kubatsira kuwana yunifomu yemhangura ukobvu.

Voids uye Pinholes:

Voids uye pinholes mumhangura layer zvinogona kukuvadza magetsi ekubatanidza uye kuwedzera njodzi yekuora. Kudzora kwakaringana kweplating paramita uye kushandiswa kweakakodzera ekuwedzera kunogona kuderedza kuitika kwevoids uye pinholes.

Surface roughness:

Yakawandisa pamusoro roughness inogona kukanganisa PCB kuita, zvichikanganisa solderability uye kuvimbika kwemagetsi. Kudzora kwakaringana kwemhangura deposition paramita, pamusoro pre-kurapwa uye post-kurapwa maitiro anobatsira kuwana yakatsetseka pamusoro pekupedzisira.

Kudzikamisa nyaya idzi uye kushomeka, kudzora kwakakodzera maitiro kunofanirwa kuitwa, kuongororwa nguva dzose uye bvunzo dzinofanirwa kuitwa, uye indasitiri zviyero nemirau inofanirwa kuteverwa. Izvi zvinogonesa kuenderana, kwakavimbika uye kwepamusoro-mhando yemhangura kuiswa paPCB. Pamusoro pezvo, kuenderera mberi kwekuvandudzwa kwemaitiro, kudzidziswa kwevashandi, uye nzira dzemhinduro dzinobatsira kuona nzvimbo dzekuvandudza uye kugadzirisa zvingangoitika zvisati zvanyanya kukomba.

Kuiswa kwemhangura paPCB substrate inhanho yakakosha muPCB kugadzira maitiro. Electroless copper deposition uye electroplating ndiyo nzira huru dzinoshandiswa, imwe neimwe iine zvayakanakira nezvainogumira. Kufambira mberi kwetekinoroji kunoramba kuchifambisa hunyanzvi mukuiswa kwemhangura, nekudaro kuvandudza kuita kwePCB uye kuvimbika.Simbiso yemhando uye kutonga kunoita basa rakakosha mukuona kugadzirwa kwemhando yepamusoro PCB. Sezvo kudiwa kwezvinhu zvidiki, zvinokurumidza, uye zvakavimbika zvemagetsi zvichiramba zvichiwedzera, ndizvo zvinoitawo kudiwa kwechokwadi uye kugona mucopper deposition tekinoroji paPCB substrates. Ongorora: Izwi rekuverenga rechinyorwa rinenge 3,500 mazwi, asi ndokumbira utarise kuti iwo chaiwo kuverenga mazwi anogona kusiyanisa zvishoma panguva yekugadzirisa uye kuongorora.

Nguva yekutumira: Sep-13-2023

Back