Nhanganyaya

Mune ino blog positi, isu tichakurukura anobudirira marongero uye indasitiri maitiro akanakisa ekudzivirira kuomarara-flex PCB delamination, nekudaro kuchengetedza midziyo yako yemagetsi kubva mukutadza.

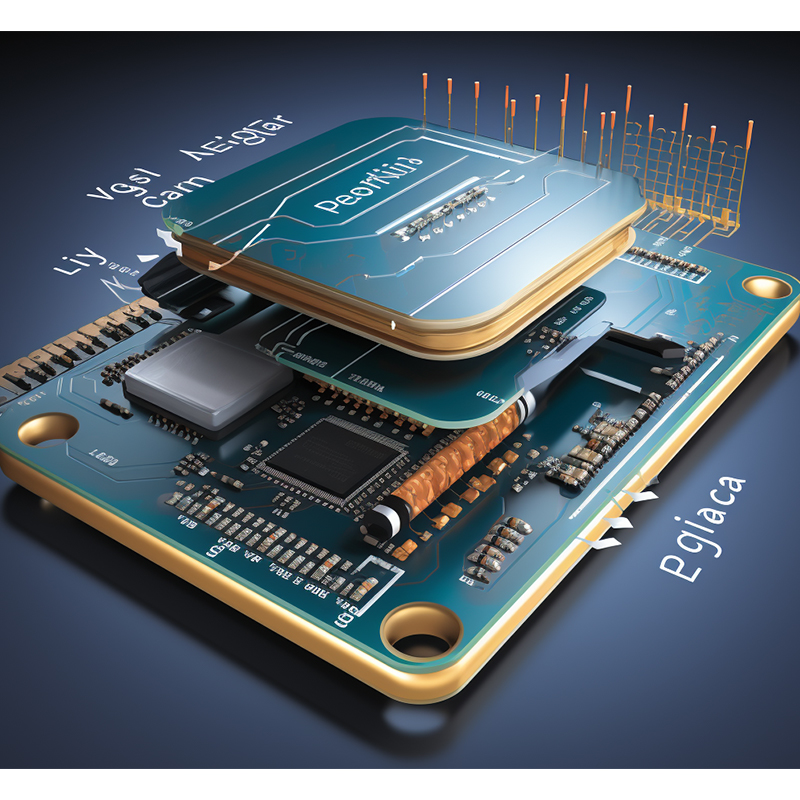

Delamination inyaya yakakomba iyo inowanzotambudza rigid-flex yakadhindwa edunhu mabhodhi (PCBs) mukati mehupenyu hwavo hwesevhisi. Ichi chiitiko chinoreva kupatsanurwa kwezvikamu muPCB, zvichikonzera kubatana kusina simba uye kutadza kwechikamu. Semugadziri kana mugadziri, zvakakosha kuti unzwisise zvinokonzeresa delamination uye kutora matanho ekudzivirira kuti uve nechokwadi chekugadzikana kwenguva refu uye kuvimbika kwePCB yako.

I. Nzwisisa delamination mu rigid-flex PCB

Delamination inokonzerwa nemhando dzakasiyana-siyana panguva yekugadzira, kuungana, uye kubata matanho eiyo rigid-flex PCBs. Kushushikana kwekupisa, kunyura kwemwando uye kusarudzwa kwezvinhu zvisina kufanira ndizvo zvinowanzoitika zvikonzero zve delamination. Kuziva nekunzwisisa zvikonzero izvi zvakakosha pakugadzira nzira dzekudzivirira dzinoshanda.

1. Thermal stress: Coefficient of thermal expansion (CTE) mismatch pakati pezvinhu zvakasiyana-siyana zvinogona kutungamirira kune kunyanya kunetseka panguva yekupisa bhasikoro, zvichiita kuti delamination.Kana PCB ikasangana nekushanduka kwekushisa, zvidimbu zvinowedzera uye zvibvumirano pamitengo yakasiyana, zvichigadzira kusawirirana muzvisungo pakati pavo.

2. Kunyura kwemvura: yakaoma flexible PCB inowanzoonekwa kune yakakwirira humidity nharaunda uye inotora unyoro nyore.Mamorekuru emvura anogona kupinda pamusoro pebhodhi kuburikidza nemamicrocracks, voids, kana kuvhurwa zvisina kuvharwa zvakanaka, zvichikonzera kuwedzera kwenzvimbo, kuzvimba, uye pakupedzisira delamination.

3. Kusarudzwa Kwezvinhu: Kunyatsofunga nezvezvinhu zvezvinhu zvakakosha pakudzivirira delamination.Izvo zvakakosha kuti usarudze yakakodzera laminate, adhesive uye pamusoro pekurapa kuti ipe yakaderera kunyorova kunyura uye kwakaringana kupisa kugadzikana.

2. Nzira dzekudzivirira delamination

Zvino zvatanzwisisa kuti sei, ngationgororei nzira dzakakosha kudzivirira kuomarara-flex PCB delamination:

1. Mafungiro ekugadzira akakodzera:

a) Deresa ukobvu hwemhangura:Kuwanda kwemhangura ukobvu kunokonzeresa kushushikana kukuru panguva yekupisa bhasikoro. Naizvozvo, kushandisa hushoma hunodiwa ukobvu hwemhangura kunowedzera PCB kuchinjika uye kunoderedza njodzi ye delamination.

b) Balanced layer structure:Edza kugovera yunifomu yezvikamu zvemhangura mukati mezvakaomarara uye zvinochinjika zvikamu zvePCB. Kuyera kwakaringana kunobatsira kuchengetedza symmetrical thermal kuwedzera uye kuderera, kuderedza mukana we delamination.

c) Controlled Tolerances:Shandisa inodzorwa kushivirira pahukuru hwegomba, kuburikidza nedhayamita uye kuteedzera hupamhi kuti ive nechokwadi chekuti kushushikana panguva yekuchinja kwemafuta kunogovaniswa zvakaenzana muPCB yese.

d) Fillets uye fillet:Mafiritsi anoderedza kushushikana mapoinzi, anobatsira kuwana yakatsetseka bend shanduko uye kuderedza mukana we delamination.

2. Kusarudzwa kwezvinhu:

a) High Tg Laminates:Sarudza laminates ane yakakwirira girazi tembiricha tembiricha (Tg) sezvo vachipa nani tembiricha kuramba, kuderedza CTE kusapindirana pakati zvinhu, uye kuderedza kupisa cycling maitiro stratified ngozi.

b) Yakaderera CTE zvinhu:Sarudza zvinhu zvine yakaderera CTE kukosha kudzikisa kupisa kwekuwedzera kusawirirana pakati pematanho akasiyana, nekudaro kuderedza kushushikana nekuvandudza kuvimbika kwese kweakaomesesa-flex PCBs.

c) Zvishandiso zvinodzivirira hunyoro:Sarudza zvinhu zvine hunyoro hwekunyudza hushoma kuderedza njodzi yekunyungudika nekuda kwekutorwa kwehunyoro. Funga kushandisa machira ane hunyanzvi kana zvisimbiso kuchengetedza nzvimbo dzisina njodzi dzePCB kubva mukupindirwa kwemwando.

3. Maitiro Akasimba Ekugadzira:

a) Kudzorwa Impedance:Ita inodzorwa impedance yekugadzira maitiro ekudzikisa kushushikana shanduko paPCB panguva yekushanda, nekudaro ichidzikisa njodzi yeku delamination.

b) Kuchengeta Kwakakodzera uye Kubata:Chengetedza uye ubate maPCB munzvimbo inodzorwa ine hunyoro hunodzorwa kudzivirira kunyudza hunyoro uye zvine chekuita nedelamination nyaya.

c) Kuongorora uye Kuongorora:Kuomarara kuyedzwa uye maitiro ekuongorora anoitwa kuti aone chero chingave chinokanganisa kugadzira chinogona kukonzera delamination. Kuita kusaparadza nzira dzekuyedza senge thermal cycling, microsectioning, uye scanning acoustic microscopy inogona kubatsira kuona yakavanzika delaminations kutanga.

Mhedziso

Kudzivirira delamination ye-rigid-flex PCBs kwakakosha kuti uve nechokwadi chekugara kwavo kwenguva refu uye kuita kwakavimbika. Iwe unogona kuderedza njodzi yeku delamination nekunzwisisa zvinokonzeresa uye kutora matanho akakodzera panguva yekugadzira, kusarudzwa kwezvinhu, uye kugadzira.Kuita manejimendi akakodzera ekupisa, kushandisa zvinhu zvine zvivakwa zvakanaka, kushandisa maitiro akasimba ekugadzira, uye kuita bvunzo dzakakwana zvinogona kuvandudza zvakanyanya kunaka uye kuvimbika kweiyo rigid-flex PCBs. Nekutevera mazano aya uye kugara uchifambirana nezvino kufambira mberi muzvigadzirwa uye matekinoroji ekugadzira, unogona kuve nechokwadi chebudiriro yebudiriro yemaPCB akasimba uye akavimbika ayo anopa kugadzikana uye kutendeseka kwemidziyo yako yemagetsi.

Nguva yekutumira: Sep-20-2023

Back