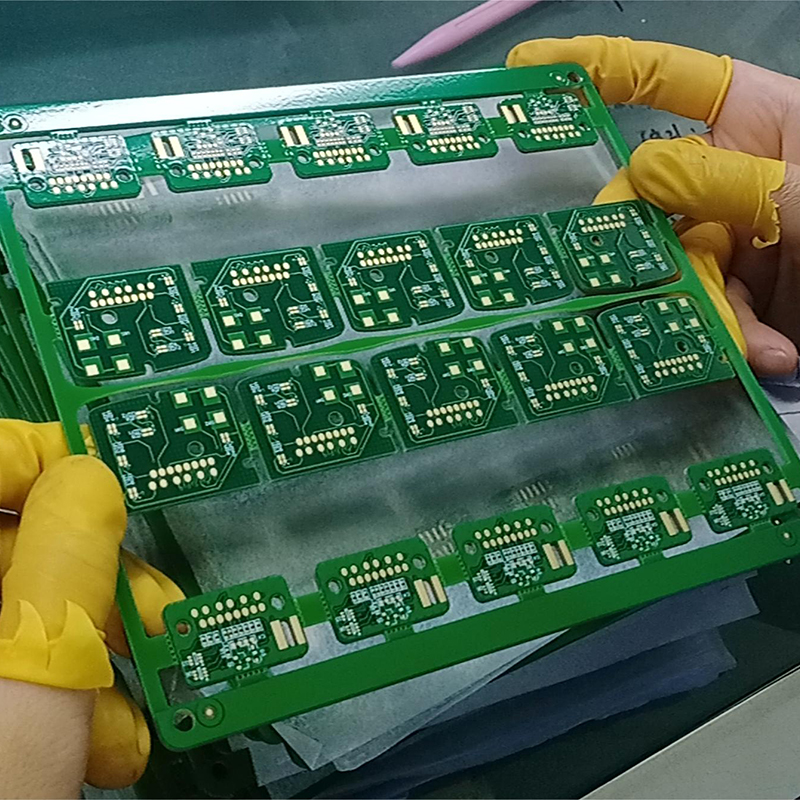

Iko kukurumidza kusimudzira kweindasitiri yemagetsi kwakonzera kushandiswa kwakakura kweiyo rigid-flex board. Nekudaro, nekuda kwekusiyana kwesimba, tekinoroji, ruzivo, maitiro ekugadzira, kugona kwekuita uye gadziriso yemidziyo yevagadziri vakasiyana, matambudziko emhando yeakaomesesa-flex mabhodhi muhuwandu hwekugadzira maitiro akasiyana zvakare.Iyo inotevera Capel ichatsanangura zvakadzama matambudziko maviri akajairika uye zvigadziriso zvichaitika mukuwanda kugadzirwa kwemabhodhi anochinjika akaomesesa.

Mukugadzirwa kwehuwandu hwemabhodhi akaomeswa-flex, tinning isina kunaka idambudziko rinowanzoitika. Tinning isina kunaka inogona kukonzera kusagadzikana

solder majoini uye kukanganisa chigadzirwa kuvimbika.

Heano zvimwe zvikonzero zvinogona kukonzera kusakwana kwetinning:

1. Dambudziko rekuchenesa:Kana iyo yedunhu bhodhi pamusoro isina kunyatsocheneswa pamberi petinning, inogona kutungamirira kune yakashata soldering;

2. Tembiricha yekubatira haina kukodzera:kana tembiricha yekunyungudutsa yakanyanya kana yakaderera, inogona kutungamira mukutadza tinning;

3. Solder paste mhando matambudziko:yakaderera-mhando solder paste inogona kutungamirira kune urombo tinning;

4. Matambudziko emhando yeSMD zvikamu:Kana iyo pad mhando yeSMD zvikamu zvisina kunaka, zvinozotungamira kune yakashata tinning;

5. Kusaita welding kushanda:Kusashanda zvakanaka kwewelding kunogona kukonzera kushata kwetinning.

Kuti udzivise zvirinani kana kugadzirisa aya matambudziko asina kunaka ekutengesa, ndapota teerera kune anotevera mapoinzi:

1. Ita shuwa kuti bhodhi repamusoro rakanyatsocheneswa kubvisa mafuta, guruva uye kumwe kusvibiswa kusati kwaitwa tinning;

2. Kudzora tembiricha nenguva yetinning: Mukuita tinning, zvakakosha kudzora tembiricha nenguva yekupinza. Iva nechokwadi chekushandisa tembiricha yekudziya yekudziya uye ita zvigadziriso zvakakodzera zvinoenderana nemidziyo yekusimbisa uye zvinodiwa. Kuwedzera tembiricha uye kurebesa Nguva inogona kuita kuti majoini e solder awedzere kana kunyungudika, uye kunyange kukonzera kukanganisa kune rigid-flex board. Kusiyana neizvi, tembiricha yakaderera uye nguva inogona kuita kuti solder zvinhu zvisakwanise kunyorova zvachose uye kupararira kune iyo solder joint, nokudaro kugadzira isina simba solder joint;

3. Sarudza yakakodzera solder material: sarudza yakavimbika solder paste supplier, iva nechokwadi chokuti inofananidzwa nezvinhu zve rigid-flex board, uye iva nechokwadi chokuti mamiriro ekuchengetedza uye kushandisa solder paste akanaka.

Sarudza zvigadzirwa zvemhando yepamusoro-soro kuti uve nechokwadi chekuti zvinhu zvekutengesa zvine kunyorova kwakanaka uye nzvimbo yekunyungudika kwakakodzera, kuitira kuti zvigovane kugovaniswa uye kugadzira majoini akagadzikana ekutengesa panguva yekugadzira tinning;

4. Iva nechokwadi chekushandisa zvakanaka zvigamba zvikamu, uye tarisa flatness uye kupfeka kwepadhi;

5. Kudzidzira nekuvandudza hunyanzvi hwekuita welding kuti ive nechokwadi cheiyo nzira yekushongedza uye nguva;

6. Chengetedza kukora uye kufanana kwetini: iva nechokwadi chokuti tini yakagoverwa zvakaenzana panzvimbo ye soldering kuti udzivise kuisa pfungwa uye kusaenzana. Maturusi akakodzera uye matekiniki, semichina yekutena kana otomatiki tinning midziyo, inogona kushandiswa kuve nechokwadi kugovaniswa nekukora kwakafanira kwemidziyo yekusodha;

7. Kuongorora nguva dzose uye kuongororwa: Kuongororwa nguva dzose uye kuongororwa kunoitwa kuti kuve nechokwadi chehutano hwemajoini ekutengesa e-rigid-flex board. Unhu uye kuvimbika kwemajoini ekutengesa kunogona kuongororwa uchishandisa kuongorora kwekuona, kudhonza kuedza, nezvimwewo. Tsvaga uye kugadzirisa dambudziko rekushaya tinning munguva yekudzivisa matambudziko ehutano uye kukundikana mukugadzirwa kwakatevera.

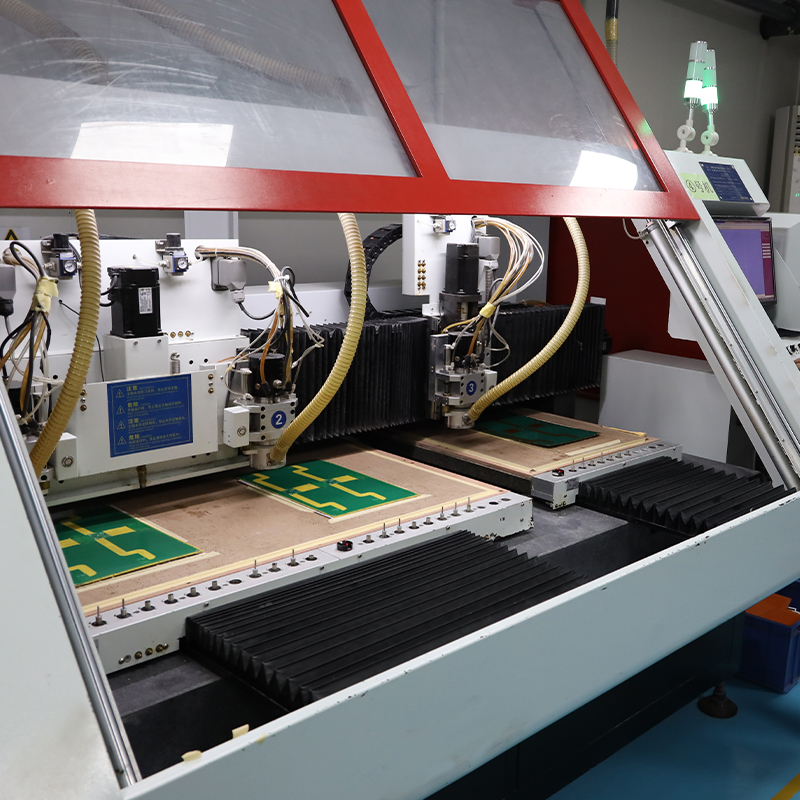

Kusakwana gomba kukora kwemhangura uye gomba risina kuenzana copper plating ndiwo matambudziko anogona kuitika mukugadzirwa kwakawanda

rigid-flex boards. Kuitika kwematambudziko aya kunogona kukanganisa kunaka kwechigadzirwa. Zvinotevera zvinoongorora zvikonzero uye

mhinduro dzinogona kukonzera dambudziko iri:

Chikonzero:

1. Dambudziko rekutanga kurapwa:Pamberi pe electroplating, pretreatment yegomba rusvingo kwakakosha zvikuru. Kana paine matambudziko akadai sekuora, kusvibiswa kana kusaenzana mumadziro egomba, zvinokanganisa kufanana uye kunamatira kweiyo plating process. Ita shuwa kuti madziro egomba akanyatsocheneswa kuti abvise chero tsvina uye oxide layer.

2. Dambudziko rekugadzira mhinduro yeplating:Iyo isiriyo plating mhinduro yekugadzira inogona zvakare kutungamira kune isina kuenzana plating. Iko kuumbwa uye kusungirirwa kweiyo plating solution kunofanirwa kunyatsodzorwa uye kugadziridzwa kuti ive nechokwadi chekufanana uye kugadzikana panguva yeplating process.

3. Dambudziko re electroplating parameters:electroplating parameters zvinosanganisira ikozvino density, electroplating nguva uye tembiricha, etc. Kusarurama plating paramita marongero anogona kutungamirira matambudziko kusaenzana plating uye kusakwana ukobvu. Ita shuwa kuti plating paramita yakagadzikwa zvinoenderana nezvinodiwa zvechigadzirwa uye gadzirisa zvinodiwa uye kuongorora.

4. Maitiro ekugadzirisa nyaya:Matanho ekuita uye mashandiro mukuita kwe electroplating kuchakanganisawo kufanana uye kunaka kwe electroplating. Ita shuwa kuti vashandisi vanonyatsotevedzera mafambiro uye kushandisa midziyo yakakodzera uye maturusi.

Solution:

1. Gadzirisai pretreatment process kuti ive nechokwadi chekuchena uye flatness yegomba madziro.

2. Nguva dzose chengetedza uye gadzirisa kugadzirwa kwe electroplating solution kuti uone kugadzikana kwayo uye kufanana.

3. Seta maparameter akakodzera ekuisa zvinoenderana nezvinodiwa zvechigadzirwa, uye tarisa uye gadzirisa zvakanyanya.

4. Kuita kudzidziswa kwevashandi kuvandudza hunyanzvi hwekuita basa uye kuziva.

5. Isai hutano hwehutano hwehutano kuti uone kuti imwe neimwe yekubatanidza yakave yakanyatsogadziriswa yehutano uye kuongororwa.

6. Simbisa kutariswa kwedata uye kurekodha: gadzira iyo yakazara data manejimendi uye yekurekodha sisitimu yekurekodha mhinduro dzebvunzo dzegomba mhangura ukobvu uye plating kufanana. Kuburikidza nehuwandu uye kuongororwa kwedata, mamiriro asina kujairika egomba mhangura ukobvu uye electroplating kufanana kunogona kuwanikwa munguva, uye matanho anoenderana anofanirwa kutorwa kugadzirisa nekuvandudza.

Izvo zviri pamusoro ndiwo matambudziko maviri makuru ekutadza kuita tinning, kusakwana kwegomba ukobvu hwemhangura, uye gomba risina kuenzana copper plating inowanzoitika mu rigid-flex board.Ndinovimba kuti kuongorora uye nzira dzakapihwa neCapel dzichabatsira kune wese munhu. Kuti uwane mamwe mimwe mibvunzo yakadhindwa yebhodhi redunhu, ndapota bvunza timu yeCapel nyanzvi, makore gumi nemashanu edunhu redunhu nyanzvi uye ruzivo rwehunyanzvi achaperekedza chirongwa chako.

Nguva yekutumira: Aug-21-2023

Back