Mune ino blog, isu tichakurukura maitiro akajairwa ekusodha anoshandiswa muakaomesesa-flex PCB musangano uye maitiro avanoita kuvimbika kwese uye kushanda kwezvishandiso zvemagetsi izvi.

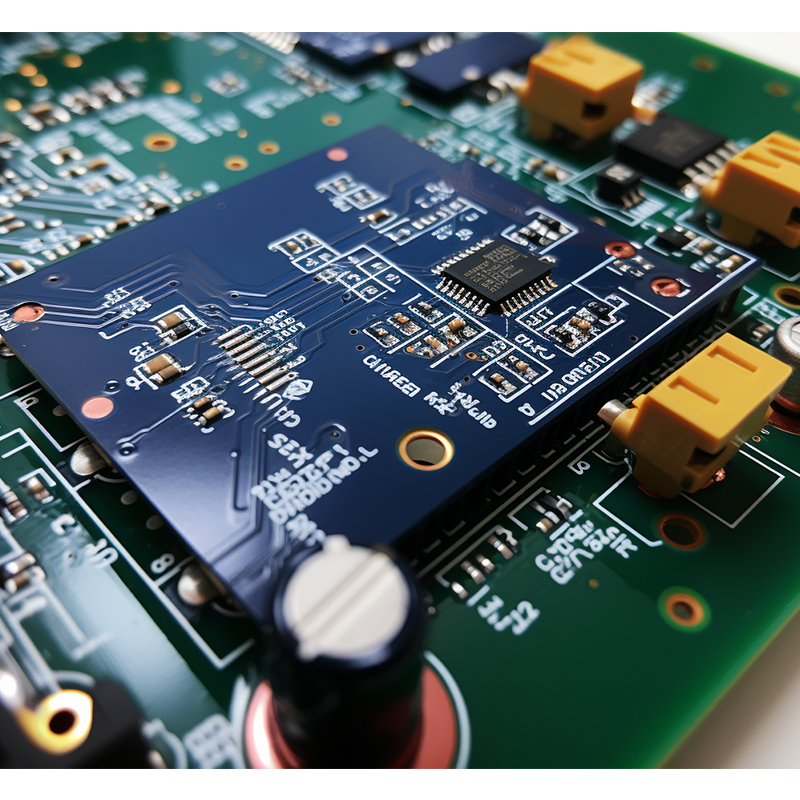

Soldering tekinoroji inoita basa rakakosha mukusangana kweiyo rigid-flex PCB. Aya mabhodhi akasiyana akagadzirwa kuti ape musanganiswa wekusimba uye kuchinjika, zvichiita kuti zvive zvakanaka kune zvakasiyana-siyana zvekushandisa apo nzvimbo inogumira kana yakaoma yekubatanidza inodiwa.

1. Surface mount tekinoroji (SMT) mune yakasimba flex PCB kugadzira:

Surface Mount tekinoroji (SMT) ndeimwe yeanonyanya kushandiswa tekinoroji ekutengesa mune rigid-flex PCB musangano. Iyo tekinoroji inosanganisira kuisa pamusoro peiyo mount components pabhodhi uye kushandisa solder paste kuti zvibate panzvimbo. Solder paste ine zvidiki solder zvimedu zvakamiswa mukuyerera izvo zvinobatsira mukugadzirisa.

SMT inogonesa huwandu hwechikamu chepamusoro, zvichibvumira huwandu hukuru hwezvikamu kuti zvigadzirwe pamativi ese ePCB. Iyo tekinoroji inopawo yakagadziridzwa yekupisa uye yemagetsi kuita nekuda kweipfupi conductive nzira dzakagadzirwa pakati pezvikamu. Nekudaro, zvinoda kunyatso kudzora kweiyo welding maitiro kudzivirira solder mabhiriji kana kusakwana solder majoini.

2. Kuburikidza negomba tekinoroji (THT) mune rigid flex PCB facbrication:

Nepo zvinhu zvekukwira pamusoro zvichiwanzo shandiswa pane dzakaomarara-flex PCBs, kuburikidza-gomba zvinhu zvinodiwawo mune dzimwe nguva. Kuburikidza ne-hole tekinoroji (THT) inosanganisira kuisa chikamu chinotungamira mugomba paPCB nekuchitengesa kune rimwe divi.

THT inopa simba remagetsi kuPCB uye inowedzera kuramba kwayo kune mechanical stress uye vibration. Inobvumira kuiswa kwakachengeteka kwezvikamu zvakakura, zvinorema izvo zvingave zvisina kukodzera SMT. Nekudaro, THT inoguma munzira dzakareba uye inogona kudzikisira PCB kuchinjika. Naizvozvo, zvakakosha kurova chiyero pakati peSMT neTHT zvikamu muakaomesesa-flex PCB magadzirirwo.

3. Kupisa kwemhepo kuyera (HAL) mukugadzira PCB yakaoma:

Kupisa mhepo yekuyera (HAL) inzira yekusimbisa inoshandiswa kuisa chidimbu chesolder kune yakafumurwa mitsetse yemhangura pane yakaoma-flex PCBs. Iyo tekinoroji inosanganisira kupfuudza PCB kuburikidza nekugeza yeakanyungudutswa solder uye wozoisa pachena kumhepo inopisa, iyo inobatsira kubvisa yakawandisa solder uye kugadzira nzvimbo yakati sandara.

HAL inowanzo shandiswa kuve nechokwadi chekutengesa kwakaringana kwemavara emhangura akafumurwa uye nekupa inodzivirira yakanangana neoxidation. Inopa yakanaka yakazara solder kufukidzwa uye inovandudza solder joint kuvimbika. Nekudaro, HAL inogona kunge isiri yakakodzera kune ese akaomesesa-flex PCB magadzirirwo, kunyanya ayo ane chaiyo kana yakaoma wedunhu.

4. Sarudza welding mune rigid flex PCB inogadzira:

Selective soldering inzira inoshandiswa kusarudza solder yakananga zvinhu kune rigid-flex PCBs. Iyi nzira inosanganisira kushandisa wave soldering kana soldering iron kunyatsoisa solder kune dzakati nzvimbo kana zvikamu paPCB.

Kusarudza solder kunonyanya kubatsira kana pane zvinopisa-sensitive components, connectors, kana nzvimbo dzakakwirira-density dzisingagoni kumira kutonhora kwakanyanya kwe reflow soldering. Iyo inobvumira kudzora zviri nani kweiyo welding process uye inoderedza njodzi yekukuvadza inonzwisisika zvikamu. Nekudaro, yakasarudzika soldering inoda kumwe kuseta uye hurongwa uchienzaniswa nemamwe matekiniki.

Kupfupisa, matekinoroji anowanzo shandiswa welding yeakaomesesa-flex board musangano anosanganisira pamusoro pepamusoro-soro tekinoroji (SMT), kuburikidza-gomba tekinoroji (THT), inopisa mhepo yekuyera (HAL) uye yakasarudzika welding.Imwe neimwe tekinoroji ine zvayakanakira uye kufunga kwayo, uye sarudzo inoenderana nezvinodiwa chaizvo zvePCB dhizaini. Nekunzwisisa matekinoroji aya uye nezvaanoreva, vagadziri vanogona kuve nechokwadi chekuvimbika uye kushanda kweakaomesesa-flex PCBs mumhando dzakasiyana dzekushandisa.

Nguva yekutumira: Sep-20-2023

Back