Kana FPC inoshanduka redunhu bhodhi yakakotama, mhando dzekushushikana pamativi ese eiyo musimboti mutsara dzakasiyana.

Izvi zvinokonzerwa nemasimba akasiyana anoshanda mukati nekunze kwenzvimbo yakakombama.

Parutivi rwemukati rwenzvimbo yakakomberedzwa, iyo FPC inoiswa pasi pekudzvinyirira. Izvi zvinodaro nekuti zvinhu zvakatsikirirwa uye kusvinwa sezvainokotama mukati. Kutsikirirwa uku kunogona kuita kuti zvidimbu zviri mukati meFPC zvitsikidzwe, zvichikonzera delamination kana kuputika kwechikamu.

Kunze kwenzvimbo yakakomberedzwa, iyo FPC inoiswa pasi pekunetseka kwekunetseka. Izvi zvinodaro nekuti chinhu chinotambanudzwa kana chakagova kunze. Mhangura inotevedzwa uye conductive zvinhu pane zvekunze zvingave zvichiiswa kune tension iyo inogona kukanganisa kutendeseka kwedunhu. Kuti ubvise kushushikana paFPC panguva yekukotama, zvakakosha kugadzira iyo flex wedunhu uchishandisa zvinhu zvakakodzera uye nzira dzekugadzira. Izvi zvinosanganisira kushandisa zvinhu zvine kuchinjika kwakakodzera, ukobvu hwakakodzera, uye kufunga nezvehushoma bend radius yeFPC. Kusimbisa kwakakwana kana zvimiro zvekutsigira zvinogona zvakare kuitwa kugovera kushushikana zvakanyanya kuenzana mudunhu rese.

Nekunzwisisa mhando dzekushushikana uye kutora kwakaringana dhizaini, kuvimbika uye kusimba kweFPC inochinjika edunhu mabhodhi kana akakotama kana kuchinjika anogona kuvandudzwa.

Izvi zvinotevera mamwe magadzirirwo ekufunga anogona kubatsira kuvandudza kuvimbika uye kusimba kweFPC inochinjika edunhu mabhodhi kana akakotama kana kuchinjika:

Kusarudzwa kwezvinhu:Kusarudza zvinhu zvakakodzera kwakakosha. A flexible substrate ine zvakanaka kushanduka uye simba remagetsi rinofanira kushandiswa. Flexible polyimide (PI) isarudzo yakajairika nekuda kwekugadzikana kwayo kwekupisa uye kuchinjika.

Circuit Layout:Kurongeka kwakakodzera kwedunhu kwakakosha kuve nechokwadi chekuti conductive traces uye zvikamu zvinoiswa uye kufambiswa nenzira inoderedza kushushikana kwekushushikana panguva yekukotama. Inokurudzirwa kushandisa makona akakomberedzwa panzvimbo yemakona akapinza.

Kusimbisa uye Kutsigira Zvimiro:Kuwedzera kusimbisa kana zvimiro zvekutsigira pamwe nenzvimbo dzakakomba dzekukotama zvinogona kubatsira kugovera kushushikana zvakanyanya uye kudzivirira kukuvara kana delamination. Reinforcement layers kana mbabvu dzinogona kuiswa kune dzakanangana nzvimbo kuti ivandudze yakazara mechanic kutendeseka.

Bending Radius:Minimum bending radii inofanirwa kutsanangurwa uye kutariswa panguva yekugadzira chikamu. Kupfuura iyo shoma bend radius inozoguma nekunyanya kunetseka kunetseka uye kukundikana.

Dziviriro uye Encapsulation:Dziviriro senge conformal coatings kana encapsulation zvinhu zvinogona kupa yakawedzera simba remuchina uye kudzivirira maseketi kubva kune zvakatipoteredza zvinhu zvakaita sehunyoro, guruva, uye makemikari.

Kuedzwa uye Kusimbiswa:Kuita kuyedza kwakadzama uye kusimbisa, kusanganisira mechanical bend uye flex bvunzo, zvinogona kubatsira kuongorora kuvimbika uye kusimba kweFPC inoshanduka edunhu mabhodhi pasi pemamiriro epasirese.

Mukati meiyo curved surface idzvinyiriro, uye kunze kunotena. Hukuru hwekushushikana hune hukama nehupamhi uye kubhenda radius yeFPC inoshanduka redunhu bhodhi. Kunyanya kushushikana kuchaita kuti FPC ishanduke redunhu bhodhi lamination, mhangura foil kuputsika uye zvichingodaro. Naizvozvo, iyo lamination chimiro cheFPC chinochinjika chedunhu bhodhi chinofanira kurongeka zvine mutsindo mukugadzira, kuitira kuti migumo miviri yepakati mutsara wenzvimbo yakakombama inofanira kunge yakaenzana sezvinobvira. Panguva imwecheteyo, iyo shoma yekukotama radius inofanirwa kuverengerwa zvinoenderana neakasiyana mamiriro ekushandisa.

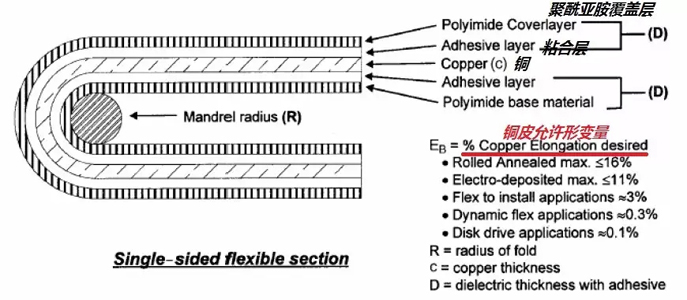

Mamiriro ezvinhu 1. Iko kupeta kudiki kwekamwe-side FPC flexible circuit board inoratidzwa mumufananidzo unotevera:

Hudiki hwayo hwekukotama radius inogona kuverengerwa neinotevera fomula: R= (c/2) [(100-Eb) /Eb]-D

Iyo shoma yekupeta radius yeR =, ukobvu hwec = ganda remhangura (yuniti m), ukobvu hweiyo D = yekuvhara firimu (m), iyo inobvumidzwa deformation yeEB = ganda remhangura (yakayerwa nezana).

Iyo deformation yeganda remhangura inosiyana nemhando dzakasiyana dzemhangura.

Iyo yakanyanya deformation yeA uye yakatsikirirwa mhangura iri pasi pe16%.

Iyo yakanyanya deformation yeB uye electrolytic mhangura isingasviki 11%.

Uyezve, iyo mhangura yemukati yechinhu chimwe chete yakasiyana mune dzakasiyana nguva dzekushandisa. Kwenguva imwe chete yekukotama, muganho wekukosha kweiyo yakaoma mamiriro ekuputsika inoshandiswa (kukosha ndeye 16%). Kune yekumisikidza yekumisikidza dhizaini, shandisa iyo yakaderera deformation kukosha inotsanangurwa neIPC-MF-150 (yemhangura yakakungurutswa, kukosha ndeye 10%). Kune anochinja-chinja maapplication, deformation yeganda remhangura ndeye 0.3%. Nekushandiswa kwemagineti musoro, deformation yeganda remhangura ndeye 0.1%. Nekuisa iyo inobvumirwa deformation yeganda remhangura, iyo yakaderera radius ye curvature inogona kuverengerwa.

Dynamic kuchinjika: chiitiko cheiyi mhangura yeganda application inoonekwa ne deformation. Semuenzaniso, phosphor bullet muIC kadhi chikamu cheIC kadhi chakaiswa muchip mushure mekuiswa kweIC kadhi. Mukuita kwekupinza, goko rinoremara nguva dzose. Ichi chiitiko chekushandisa chinochinjika uye chine simba.

Iyo idiki yekupeta radius yeimwe-sided inochinjika PCB inoenderana nezvinhu zvakati wandei, zvinosanganisira zvinhu zvinoshandiswa, ukobvu hwebhodhi, uye zvakanangana nezvinodiwa zvekushandisa. Kazhinji, iyo inobhenda radius ye flex circuit board ingangoita kagumi kukora kwebhodhi. Semuyenzaniso, kana ukobvu hwebhodhi huri 0.1mm, iyo shoma yekubhenda radius inenge 1mm. Izvo zvakakosha kuti uzive kuti kupeta bhodhi pazasi peiyo diki bend radius inogona kukonzera kusagadzikana, kunetsa pane conductive traces, uye pamwe kuputika kana delamination yebhodhi. Kuti uchengetedze hutano hwemagetsi uye hwemagetsi edunhu, zvakakosha kuomerera kune yakakurudzirwa bend radii. Zvinokurudzirwa kubvunza mugadziri kana mutengesi webhodhi rinochinjika kune chaiyo bending radius nhungamiro uye kuve nechokwadi chekuti dhizaini uye zvinodiwa zvekushandisa zvinosangana. Pamusoro pezvo, kuita bvunzo dzemakanika uye kusimbiswa kunogona kubatsira kuona yakanyanya kushushikana iyo bhodhi inogona kumira pasina kukanganisa kushanda kwayo uye kuvimbika.

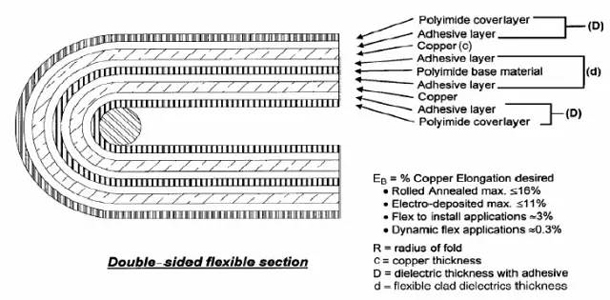

Situation 2, kaviri-mativi bhodhi reFPC inoshanduka redunhu bhodhi sezvinotevera:

Pakati pazvo: R= zvishoma kubhenda radius, unit m, c= copper skin thick, unit m, D= coverage film thick, unit mm, EB= copper skin deformation, inoyerwa nepercent.

Kukosha kweEB kwakafanana nepamusoro.

D= interlayer yepakati ukobvu, unit M

Iyo idiki yekupeta radius yekaviri-mativi FPC (Flexible Printed Circuit) inochinjika yedunhu bhodhi inowanzova yakakura kupfuura iyo yepaneri-rimwe divi repaneru. Izvi zvinodaro nekuti mapaneru ane mativi maviri ane conductive traces pamativi ese, ayo anonyanya kunetseka nekushushikana uye kunetsa panguva yekukotama. Iyo shoma yekupeta radius yekaviri-sided FPC flex pcb baord inowanzoita ka20 ukobvu hwebhodhi. Uchishandisa muenzaniso wakafanana nepakutanga, kana ndiro iri gobvu 0.1mm, iyo shoma yekubhenda radius inenge 2mm. Zvinonyanya kukosha kutevera mugadziri wacho nhungamiro uye nokurondedzerwa kwokubhenda kaviri-mativi FPC pcb mapuranga. Kupfuura yakakurudzirwa bend radius inogona kukuvadza conductive traces, kukonzera layer delamination, kana kukonzera mamwe matambudziko anokanganisa mashandiro edunhu uye kuvimbika. Zvinokurudzirwa kubvunza mugadziri kana mutengesi kune chaiwo bend radius dhairekitori, uye kuita mekiniki yekuyedza uye kuona kuti bhodhi rinokwanisa kumirisana nemabhendi anodiwa pasina kukanganisa kuita kwayo.

Nguva yekutumira: Jun-12-2023

Back