Munguva yanhasi yekukurumidza kuvandudza tekinoroji, zvigadzirwa zvemagetsi zvave chikamu chakakosha chehupenyu hwedu hwezuva nezuva. Kubva pamafoni emafoni kusvika kumidziyo yekurapa, mabhodhi edunhu akadhindwa (PCBs) anoita basa rakakosha mukugonesa masimba aya zvishandiso. Yakakwira Density Interconnect (HDI) tekinoroji maPCB anga ari shanduko yemutambo, achipa yakakwira density density, mashandiro ari nani uye kuvimbika kwakawedzera.Asi wakambozvibvunza here kuti maHDI tekinoroji maPCB anogadzirwa sei? Muchinyorwa chino, tichanyura mukati mekuoma kwemaitiro ekugadzira uye kujekesa matanho anobatanidzwa.

1. Kusuma kupfupi kweHDI tekinoroji PCB:

HDI tekinoroji PCBs dzakakurumbira nekuda kwekugona kwavo kugarisa nhamba huru yezvikamu mu compact dhizaini, ichideredza saizi yese yemidziyo yemagetsi.Aya mabhodhi anoisa akati wandei akaturikidzana, diki vias, uye mitsetse mitete yekukura kukuru kwenzira. Pamusoro pezvo, ivo vanopa yakagadziridzwa mashandiro emagetsi, impedance control, uye chiratidzo chekuvimbika, zvichiita kuti ive yakanakira kumhanyisa-kumhanya uye yakakwirira-frequency application.

2. Dhizaini dhizaini:

Rwendo rwekugadzira rweHDI Technology PCB runotanga kubva padanho rekugadzira.Mainjiniya ane hunyanzvi uye vagadziri vanoshanda pamwechete kuti vagone kukwenenzvera dhizaini uku vachiona kuti mitemo yekugadzira uye zvipingaidzo zvinosangana. Shandisa advanced software maturusi kugadzira chaiwo madhizaini, kutsanangura layer stackups, chikamu chekuisa uye nzira. Iyo dhizaini zvakare inotora muakaundi zvinhu zvakaita sechiratidzo chekuvimbika, kutungamira kwekupisa, uye kugadzikana kwemuchina.

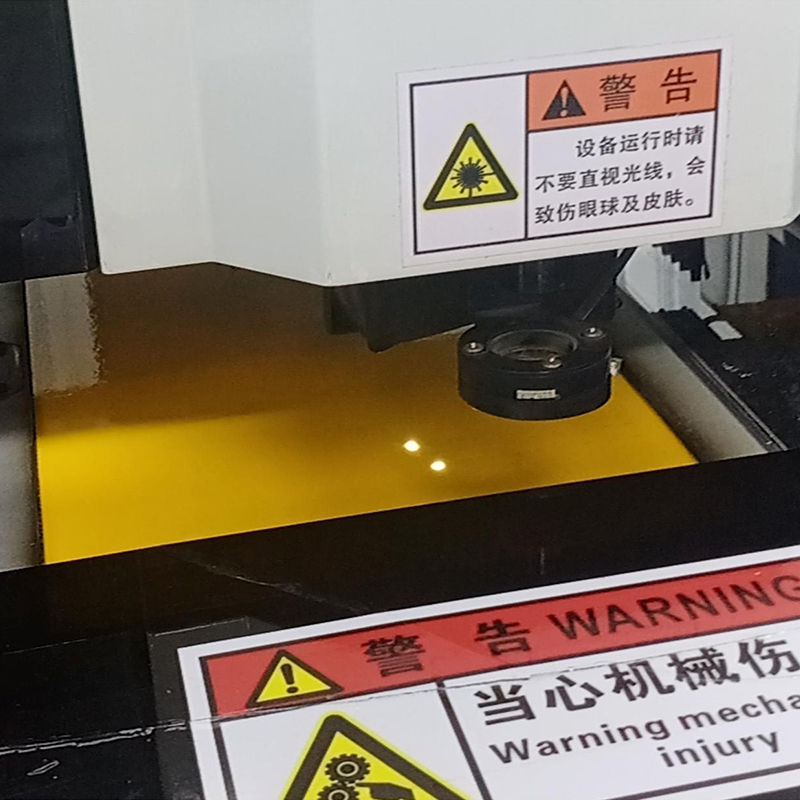

3. Laser kuchera:

Imwe yematanho akakosha muHDI tekinoroji PCB kugadzira kudhiraivha kwelaser.Laser tekinoroji inogona kugadzira diki, yakanyatsojeka vias, izvo zvakakosha kuti uwane yakakwirira redunhu densities. Laser drilling machines inoshandisa high-energy danda rechiedza kubvisa zvinhu kubva kune substrate uye kugadzira maburi maduku. Vias izvi zvino metallized kusika magetsi kubatana pakati siyana akaturikidzana.

4. Electroless copper plating:

Kuve nechokwadi chekubatana kwemagetsi pakati pezvikamu, electroless copper deposition inoshandiswa.Mukuita uku, madziro egomba rakaboorwa akaputirwa nehutete hwakanyanya hwemhangura inofambisa nekunyudzwa kwemakemikari. Iyi mhangura yemhangura inoshanda sembeu yeinotevera electroplating process, inosimudzira iyo yakazara adhesion uye conductivity yemhangura.

5. Lamination uye kudzvanya:

HDI Tekinoroji PCB kugadzira inosanganisira akawanda lamination uye kudzvanya matenderedzwa apo akasiyana mativi edunhu redunhu akaturikidzana uye anobatanidzwa pamwechete.Kudzvinyirirwa kwepamusoro uye tembiricha zvinoshandiswa kuve nechokwadi chekubatana kwakakodzera uye kubvisa chero mahomwe emhepo kana voids. Maitiro acho anosanganisira kushandiswa kweakasarudzika lamination midziyo kuti uwane inodiwa bhodhi ukobvu uye kugadzikana kwemichina.

6. Copper plating:

Copper plating inoita basa rakakosha muHDI tekinoroji maPCB sezvo ichimisikidza inodiwa magetsi conductivity.Maitiro acho anosanganisira kunyudza bhodhi rese mumhangura yeplating solution uye kupfuudza magetsi mairi. Kuburikidza nemaitiro e electroplating, mhangura inoiswa pamusoro pebhodhi redunhu, ichigadzira masekete, mitsetse uye maficha epamusoro.

7. Kurapwa kwepamusoro:

Kurapa kwepamusoro inhanho yakakosha mukugadzira maitiro ekuchengetedza maseketi uye kuve nechokwadi chekuvimbika kwenguva refu.Yakajairwa pamusoro pekurapa tekinoroji yeHDI tekinoroji maPCB anosanganisira kunyudzwa sirivha, kunyudzwa goridhe, organic solderability preservatives (OSP), uye electroless nickel/kunyudzwa goridhe (ENIG). Aya matekinoroji anopa inodzivirira layer inodzivirira oxidation, inovandudza solderability, uye kurerutsa kusangana.

8. Kuedza uye Kudzora Kwemhando:

Kuedza kwakasimba uye nhanho dzekudzora mhando inodiwa pamberi peHDI tekinoroji PCBs dzaunganidzwa mumidziyo yemagetsi.Automated optical inspection (AOI) uye magetsi ekuongorora (E-test) anowanzoitwa kuti aone nekugadzirisa chero kukanganisa kana matambudziko emagetsi munharaunda. Aya maedzo anovimbisa kuti chigadzirwa chekupedzisira chinosangana nezvinodiwa uye chinoita zvakavimbika.

Mukupedzisa:

HDI Tekinoroji maPCB akashandura indasitiri yemagetsi, kufambisa kugadzirwa kwezvidiki, zvakareruka, uye zvine simba zvemagetsi zvigadzirwa.Kunzwisisa maitiro akaomarara ekugadzira kuseri kwemabhodhi aya kunosimbisa mwero wekurongeka uye hunyanzvi hunodiwa kugadzira emhando yepamusoro HDI tekinoroji PCB. Kubva pakugadzira kwekutanga kuburikidza nekuchera, plating uye kugadzirira kwepamusoro, nhanho yega yega yakakosha kuti ive nechokwadi chekuita kwakanyanya uye kuvimbika. Nekushandisa nzira dzepamusoro dzekugadzira uye kuomerera kune dzakaomesesa kudzora mhando, vagadziri vanogona kusangana nezvinogara zvichichinja zvinodiwa pamusika wemagetsi uye kugadzira nzira yekubudirira.

Nguva yekutumira: Sep-02-2023

Back