Munyika yemabhodhi edunhu akadhindwa (PCBs), kusarudzwa kwezvinhu uye maitiro ekugadzira anogona kukanganisa zvakanyanya kunaka uye kushanda kwemidziyo yemagetsi. Imwe mutsauko wakadaro ndeye gobvu goridhe PCB, iyo inopa yakasarudzika mabhenefiti pamusoro peyakajairwa PCBs.Pano isu tine chinangwa chekupa kunzwisisa kwakazara kwegobvu goridhe PCB, tichitsanangura kuumbwa kwayo, zvakanakira, uye mutsauko kubva kune echinyakare PCBs.

1.Kunzwisisa Gobvu Goridhe PCB

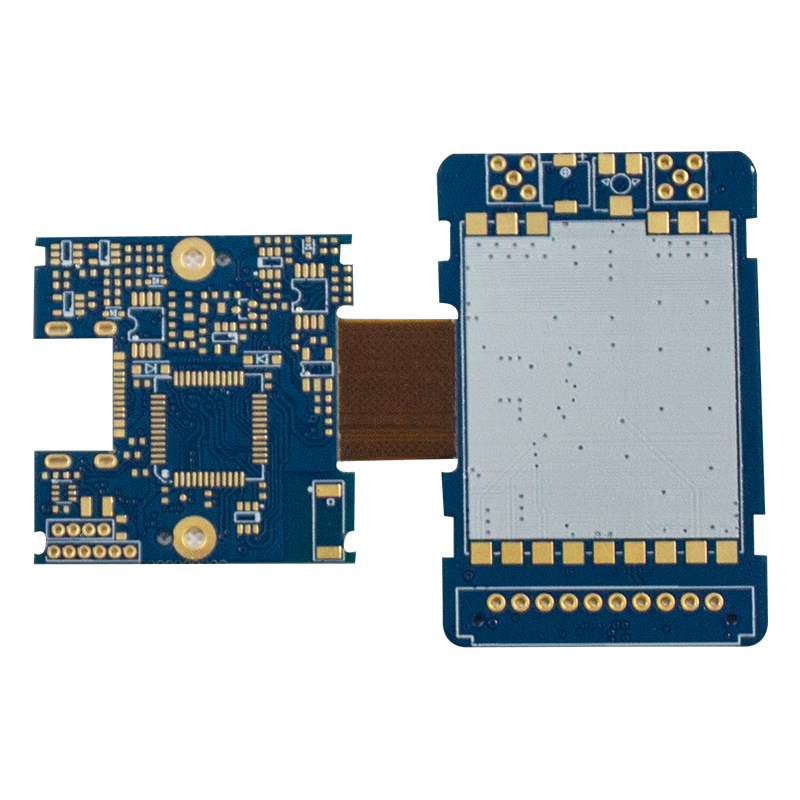

Iyo gobvu yegoridhe PCB imhando yakakosha yeakadhindwa redunhu bhodhi iro rine gobvu regoridhe rakanyanya pamusoro payo.Iwo anoumbwa neakawanda akaturikidzana emhangura uye dielectric zvinhu zvine goridhe layer yakawedzerwa pamusoro. MaPCB aya anogadzirwa kuburikidza ne electroplating process inoita kuti goridhe rave rakaenzana uye rakabatana zvakasimba.Kusiyana nemaPCB akajairwa, maPCB egoridhe gobvu ane goridhe rakakora zvakanyanya pakupera kwepamusoro pekupedzisira. Kukora kwegoridhe paPCB yakajairwa kunowanzoita 1-2 micro inches kana 0.025-0.05 microns. Kana tichienzanisa, maPCB akakora egoridhe anowanzo kuve negoridhe rakakora remakumi matatu-gumi nemaviri madiki inches kana 0.75-3 microns.

2.Advantages yegoridhe gobvu PCB

Makobvu egoridhe maPCB anopa akawanda mabhenefiti pamusoro pezvisarudzo zvakajairwa, zvinosanganisira kusimbaradza, kukwidziridzwa kwemaitiro uye kuita kwepamusoro.

Durability:

Imwe yemabhenefiti makuru egoridhe gobvu PCB ndeyekusimba kwavo kwakasiyana. Aya mabhodhi akagadzirirwa chaizvo kutsungirira nharaunda dzakaomarara, achiaita akanakira maapplication anowanzo kuratidzwa kune tembiricha yakanyanyisa kana mamiriro akaomarara. Ukobvu hwekuputira kwegoridhe hunopa dhizaini yekudzivirira kubva mukuora, oxidation uye mamwe marudzi ekukuvadza, kuve nechokwadi chehupenyu hurefu hwePCB.

Wedzera conductivity yemagetsi:

Makobvu egoridhe maPCB ane yakanakisa magetsi conductivity, achivaita sarudzo yekutanga yezvikumbiro zvinoda kufambiswa kwemasaini. Kuwedzera ukobvu hwegoridhe plating kunoderedza kuramba uye kunowedzera kushanda kwemagetsi, kuve nechokwadi chekufambiswa kwechiratidzo chisina musono mubhodhi. Izvi zvinonyanya kukosha kumaindasitiri akadai senhare, aerospace uye michina yekurapa, uko kwakaringana uye kwakavimbika kufambisa data kwakakosha.

Kuvandudza solderability:

Imwe mukana weiyo gobvu goridhe PCB ndiyo yakagadziridzwa solderability. Kuwedzera goridhe plating ukobvu inobvumira zviri nani solder kuyerera uye kunyorova, kuderedza mukana we solder reflow nyaya panguva yekugadzira. Izvi zvinochengetedza majoini akasimba uye akavimbika ekutengesa, kubvisa zvingangokanganisa uye kuvandudza huwandu hwechigadzirwa.

Hupenyu hwekusangana:

Mabatirwo emagetsi paPCBs dzegoridhe gobvu anogara kwenguva refu nekuda kwekuwedzera kwegoridhe replating ukobvu. Izvi zvinowedzera kuvimbika kwekusangana uye zvinoderedza njodzi yekuderedzwa kwechiratidzo kana kupindirana kwekubatanidza nekufamba kwenguva. Naizvozvo, maPCB aya anoshandiswa zvakanyanya mumashandisirwo ane yakakwirira yekuisa/kubvisa mitsetse, senge kadhi rekubatanidza kana memory modules, izvo zvinoda kwenguva refu yekubata kubata.

Natsiridza kusapfeka:

Makobvu egoridhe maPCB anoita zvakanaka mumashandisirwo anoda kudzokororwa kupfeka uye kubvaruka. Kuwedzera kukora kwegoridhe plating kunopa chipingamupinyi chinodzivirira chinobatsira kutsungirira kukwiza nekukwiza mhedzisiro yekudzokorora kushandiswa. Izvi zvinovaita vakanaka kune zvinobatanidza, touchpads, mabhatani uye zvimwe zvikamu zvinogara zvichigara zvichisangana nemuviri, kuve nechokwadi chehupenyu hwavo hurefu uye kuita kunoenderana.

Deredza kurasikirwa kwechiratidzo:

Kurasikirwa kwechiratidzo idambudziko rakajairika mune yakakwirira frequency application. Nekudaro, maPCB akakora egoridhe anopa mhinduro inoshanda inogona kuderedza kurasikirwa kwechiratidzo nekuda kwekukwidziridzwa kwavo. Aya maPCB anoratidza kushomeka kwekushomeka kuti ave nechokwadi chekuvimbika kwechiratidzo, kuderedza kurasikirwa kwekutapurirana kwedata uye kuwedzera mashandiro ehurongwa. Naizvozvo, anoshandiswa zvakanyanya mumaindasitiri akadai seyekufonerana, isina waya michina, uye yakakwirira-frequency michina.

3.Kukosha kwekuwedzera goridhe plating ukobvu kune gobvu goridhe PCBs:

Iyo yakawedzera ukobvu hwekuputira goridhe mune gobvu goridhe PCBs inoshanda zvakati wandei zvakakosha.Kutanga, inopa humwe hudziviriro kubva kune oxidation uye corrosion, kuve nechokwadi chekuvimbika kwenguva refu uye kugadzikana kunyangwe munzvimbo dzakaoma. Iyo gobvu yegoridhe yakanamira inoita sechivharidzo, ichidzivirira chero kemikari kuita pakati pemukati memhangura nemhepo yekunze, kunyanya kana yakavhenekerwa nehunyoro, mwando, kana zvinosvibisa mumaindasitiri.

Kechipiri, iyo gobvu goridhe layer inosimudzira iyo yakazara conductivity uye chiratidzo chekufambisa kugona kwePCB.Ndarama ndiyo yakanaka conductor yemagetsi, kunyangwe iri nani pane iyo mhangura inowanzo shandiswa pakuita maronda muyakajairwa maPCB. Nekuwedzera iyo goridhe zviri pamusoro, gobvu PCBs dzegoridhe dzinogona kuwana yakaderera resistivity, kuderedza kurasikirwa kwechiratidzo uye kuve nechokwadi chekuita kurinani, kunyanya mumashandisirwo epamusoro-soro kana ayo anosanganisira masaini akaderera.

Pamusoro pezvo, goridhe rakakora zvidimbu zvinopa zvirinani solderability uye yakasimba chikamu chinokwira pamusoro.Ndarama ine yakanakisa solderability, kubvumira yakavimbika solder majoini panguva gungano. Ichi chikamu chakakosha nekuti kana majoini ekutengesa asina kusimba kana kusarongeka, anogona kukonzera kutadza kwepakati kana kuzara kwedunhu. Kuwedzera kwegoridhe ukobvu zvakare kunonatsiridza kusimba kwemuchina, kuita gobvu PCBs dzegoridhe dzisabatike nekupfeka uye kubvaruka uye zvakanyanya kushingirira kune mechaniki kusagadzikana uye vibration.

Izvo zvakakosha kuti ticherechedze kuti iyo yakawedzera ukobvu hwegoridhe layer mune gobvu goridhe PCBs zvakare inounza mutengo wakakwira uchienzaniswa neyakajairwa maPCB.Iyo yakakura yegoridhe yekuisa maitiro inoda imwe nguva, zviwanikwa uye hunyanzvi, zvichikonzera kuwedzera kwekugadzira mari. Nekudaro, kune maapplication anoda emhando yepamusoro, kuvimbika uye hupenyu hurefu, iyo mari mugoridhe gobvu PCBs inowanzopfuura njodzi dzinogona kuitika uye mutengo une chekuita nekushandisa akajairwa maPCB.

4.Musiyano pakati pegoridhe gobvu PCB uye standard PCB:

MaPCB akajairwa anowanzo gadzirwa epoxy zvinhu nemhangura layer pane rimwe kana mativi ese ebhodhi. Aya mataira emhangura akaiswa panguva yekugadzira maitiro kuti agadzire inodiwa dunhu. Ukobvu hwemhangura hunogona kusiyana zvichienderana nekushandiswa, asi kazhinji huri mu 1-4 oz renji.

PCB gobvu yegoridhe, sekureva kunoita zita, ine gobvu regoridhe replating layer kana ichienzaniswa neyakajairwa PCB. MaPCB akajairwa anowanzo kuve negoridhe plating ukobvu hwe20-30 micro inches (0.5-0.75 microns), nepo PCB dzegoridhe gobvu dzine gobvu regoridhe rekuisa 50-100 madiki inches (1.25-2.5 microns).

Misiyano mikuru pakati pegoridhe gobvu PCB uye akajairwa PCBs igoridhe dhizaini ukobvu, kugadzira kuoma, mutengo, nzvimbo dzekushandisa, uye kushomeka kushanda kune yakakwirira-tembiricha nharaunda.

Ukobvu hwegoridhe:

Musiyano mukuru pakati pegoridhe gobvu PCB uye yakajairwa PCB ndiko ukobvu hwegoridhe. Goridhe PCB ine gobvu regoridhe replating layer pane yakajairwa PCB. Uku kukora kwekuwedzera kunobatsira kuvandudza kusimba kwePCB uye kushanda kwemagetsi. Iyo gobvu yegoridhe layer inopa inodzivirira iyo inosimudzira iyo PCB kuramba kukoromoka, oxidation uye kupfeka. Izvi zvinoita kuti PCB iwedzere kusimba munzvimbo dzakaoma, kuve nechokwadi chekushanda kwakavimbika kwenguva refu. Iyo gobvu goridhe plating inobvumirawo zvirinani magetsi conductivity, zvichibvumira kufambiswa kwemasaini kwakanaka. Izvi zvinonyanya kubatsira muzvishandiso zvinoda kufambiswa kwechiratidzo chepamusoro-soro kana chinomhanya-mhanya, sezvekufonerana, midziyo yekurapa, uye masisitimu emuchadenga.

Mutengo:

Kuenzaniswa neyakajairwa PCB, mutengo wekugadzira wegoridhe gobvu PCB unowanzo kwira. Mutengo wepamusoro uyu unobva pakugadzira kwacho kunoda imwe goridhe zvinhu kuti uwane ukobvu hunodiwa. Nekudaro, kuvimbika kukuru uye kuita kwegobvu PCBs dzegoridhe rinopembedza mutengo wekuwedzera, kunyanya mumashandisirwo apo zvinodiwa zvinodiwa zvinofanirwa kuzadzikiswa.

Nzvimbo dzekushandisa:

MaPCB akajairwa anoshandiswa zvakanyanya mumaindasitiri akasiyana siyana, kusanganisira zvemagetsi zvevatengi, masisitimu emotokari uye michina yemaindasitiri. Izvo zvakakodzera kune zvikumbiro apo kuvimbika kwepamusoro hakusi chinhu chinonyanya kukosha. Makobvu egoridhe maPCB, kune rumwe rutivi, anonyanya kushandiswa muminda yehunyanzvi inoda kuvimbika kwepamusoro uye kuita. Mienzaniso yenzvimbo dzekushandisa idzi dzinosanganisira indasitiri yemuchadenga, midziyo yekurapa, midziyo yemauto, uye masisitimu ekufonera. Munzvimbo idzi, mabasa akakosha anovimba neakavimbika uye emhando yepamusoro zvinhu zvemagetsi, saka gobvu PCB dzegoridhe ndiyo yekutanga sarudzo.

Manufacturing Complexity:

Kuenzaniswa neyakajairwa maPCB, maitiro ekugadzira egoridhe gobvu PCB akanyanya kuomarara uye anotora nguva. Iyo electroplating maitiro inofanirwa kunyatso dzorwa kuti iwane yainoda goridhe layer ukobvu. Izvi zvinowedzera kuoma uye nguva inodiwa yekugadzira maitiro. Kunyatso kudzora kweiyo plating process kwakakosha nekuti misiyano muhukobvu hwegoridhe inogona kukanganisa PCB kuita uye kuvimbika. Iyi inyanzvi yekugadzira maitiro inobatsira kumhando yepamusoro uye kushanda kwegoridhe gobvu PCB.

Kukodzera kushoma kwenzvimbo dzetembiricha yepamusoro:

Nepo maPCB akakora egoridhe achiita zvakanaka munzvimbo zhinji, anogona kunge asiri iwo akanyanya kufanira sarudzo yekushisa kwakanyanya. Pasi pemamiriro ekushisa akanyanya, goridhe rakakora rinogona kudzikisira kana kudzikisira, zvichikanganisa kuita kwese kwePCB.

Muchiitiko ichi, mamwe marapirwo epamusoro senge immersion tin (ISn) kana sirivheri yekunyudza (IAg) inogona kufarirwa. Mishonga iyi inopa dziviriro yakakwana pamhedzisiro yekupisa kwakanyanya pasina kukanganisa kushanda kwePCB.

Kusarudzwa kwezvinhu zvePCB zvinogona kukanganisa zvakanyanya kunaka uye kuita kwemidziyo yemagetsi. Makobvu egoridhe maPCB anopa akasiyana mabhenefiti akadai sekuwedzera kusimba, yakagadziridzwa solderability, yakanakisa magetsi conductivity, yepamusoro yekuonana kuvimbika, uye yakawedzerwa hupenyu hwesherufu.Mabhenefiti avo anoruramisa mutengo wepamusoro wekugadzira uye unovaita kuti vanyanyokodzera maindasitiri ane hunyanzvi anotungamira kuvimbika, senge aerospace, zvishandiso zvekurapa, zvechiuto, uye nharembozha masisitimu. Kunzwisisa kuumbwa, mabhenefiti, uye mutsauko pakati pegoridhe gobvu PCB uye akajairwa maPCB kwakakosha kune mainjiniya, vagadziri, uye vagadziri vari kutsvaga kukwirisa mashandiro uye hupenyu hurefu hwemidziyo yavo yemagetsi. Nekusimudzira hunhu hwakasiyana hwegoridhe gobvu PCB, vanogona kuve nechokwadi chekuvimbika uye chemhando yepamusoro zvigadzirwa kune vatengi vavo.

Nguva yekutumira: Sep-13-2023

Back