PCB prototype musangano tekinoroji inoita basa rakakosha mukugadzira uye kuungana kwemabhodhi edunhu.Aya matekinoroji anovimbisa kushanda, kwepamusoro-mhando uye hupfumi hwekugadzirwa kweprototype wedunhu mabhodhi.Mune ino blog post, isu tichaongorora mamwe akajairwa PCB prototyping ungano matekiniki. Tisati taenda kune rumwe ruzivo, ngatizivise muchidimbu Capel, kambani ine makore gumi nemashanu echiitiko muindasitiri yebhodhi redunhu, ine timu yehunyanzvi yehunyanzvi, tekinoroji yedhipatimendi redunhu prototype gungano tekinoroji, uye kugadzirwa kwayo uye fekitori yegungano.

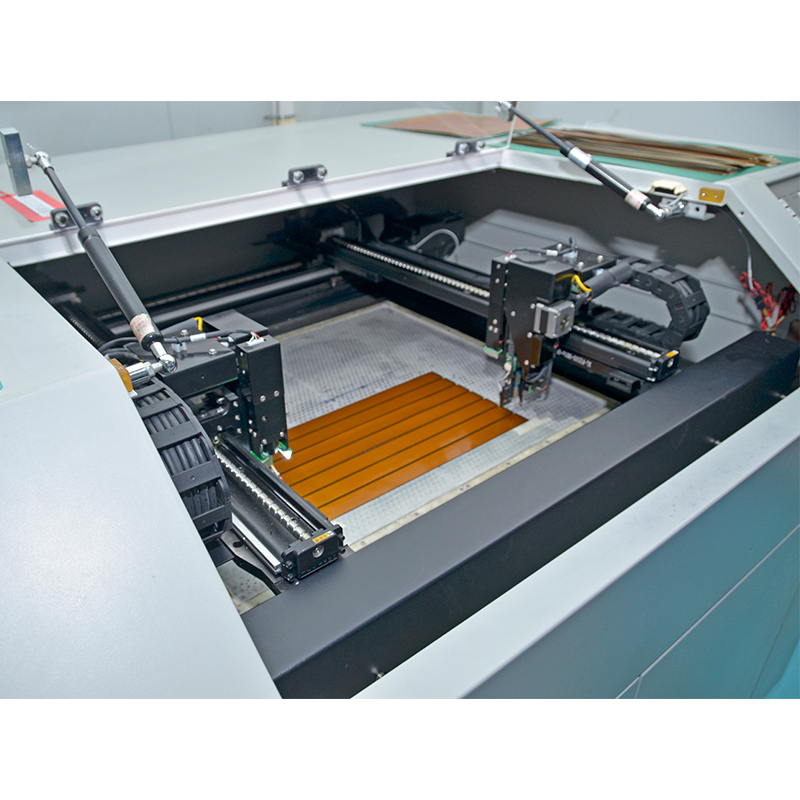

Capel anga ari mutungamiri muindasitiri yebhodhi redunhu kweanopfuura makore gumi nemashanu, akazvipira kusangana nezvinodiwa zvakasiyana zvevatengi vayo.Iyo kambani ine boka revashandi vane ruzivo vakawana ruzivo rwakakosha mukugadzira uye kuungana kwemabhodhi edunhu. Capel's advanced circuit board prototyping assembly tekinoroji inova nechokwadi chemhando yepamusoro-soro uye maitiro ekugadzira anoshanda.

Kuve neyayo yedunhu bhodhi kugadzira uye magungano zvinomera zvinopa Capel mukana wekukwikwidza.Iyi setup inobvumira kambani kudzora zvirinani maitiro ekugadzira, kuve nechokwadi chekutumira panguva uye kuchengetedza yakanakisa mhando yekutonga. Pamusoro pezvo, hunyanzvi hwekambani mukugadzirwa kwePCB nekuungana kunoita kuti ikwanise kupa vatengi mhinduro dzakakwana uye dzinodhura.

Izvozvi zvatave kujairana neCapel uye kugona kwayo, ngationgororei PCB prototyping ungano matekiniki anowanzo shandiswa mukati.

indasitiri.

1. Surface Mount tekinoroji (SMT):

Surface mount tekinoroji (SMT) ndeimwe yeanonyanya kushandiswa PCB musangano matekinoroji. Inosanganisira kukwirisa zvinhu zvakananga kuPCB pamusoro. SMT inopa zvakati wandei zvakanakira, kusanganisira kugona kugarisa zvidiki zvikamu, yakakwirira chikamu density, uye yakagadziridzwa mashandiro emagetsi.

2. Kuburikidza negomba tekinoroji (THT):

Kuburikidza ne-hole tekinoroji (THT) tekinoroji yekare yegungano inosanganisira kukwirisa zvinhu nekuisa zvinotungamira mumakomba muPCB nekuzvitengesa kune rimwe divi. THT inowanzo shandiswa kune zvikamu zvinoda kuwedzera simba remagetsi kana kuti zvakakurisa kune SMT.

3. Automatic optical inspection (AOI):

Automated optical inspection (AOI) itekinoroji inoshandiswa kuongorora maPCB akaungana kuona kukanganisa kana kukanganisa. Masisitimu eAOI anoshandisa makamera uye maalgorithms ekucherechedzwa kwemifananidzo kuongorora zvakasiyana-siyana zvePCB, sekuiswa kwechikamu, majoini ekutengesa, uye polarity. Iyi tekinoroji inovimbisa kusangana kwemhando yepamusoro uye inoderedza mukana wezvakaremara zvigadzirwa zvinosvika kune vatengi.

4. X-ray kuongorora:

X-ray yekuongorora ndeye isingaparadze yekuongorora tekinoroji inoshandiswa kuongorora maPCB kune zvakavanzika maficha, senge solder majoini kana underfill zvinhu pasi pezvikamu. Kuongororwa kweX-ray kunobatsira kuona zvikanganiso senge kusakwana solder, kutonhora solder majoini, kana voids izvo zvingave zvisingaonekwe kuburikidza nekutarisa kwekuona.

5. Rework uye kugadzirisa:

Maitiro ekugadzirisa zvakare uye ekugadzirisa akakosha pakugadzirisa zvakakanganisika kana kutsiva zvinhu zvisina kunaka pamaPCB akaungana. Vanamazvikokota vane hunyanzvi vanoshandisa maturusi ane hunyanzvi uye midziyo kugadzira uye kutsiva zvinhu pasina kukanganisa PCB. Aya maitiro anoderedza marara uye salvage mabhodhi akaremara, kuchengetedza nguva uye zviwanikwa.

6. Sarudza welding:

Selective soldering inzira inoshandiswa kutengesa kuburikidza-gomba zvinhu paPCB pasina kukanganisa zvakatengeswa pamusoro pegomo zvinhu. Inopa hukuru hwechokwadi uye inoderedza mukana wekukuvadza zvikamu zviri pedyo.

7. Muedzo Wepamhepo (ICT):

In-circuit bvunzo (ICT) inoshandisa yakasarudzika bvunzo midziyo kutarisa kushanda kwezvikamu zvedunhu paPCB. Inobatsira kuona zvisizvo zvikamu, zvakavhurika kana mapfupi maseketi kana zvisiri izvo zvechikamu kukosha. ICT inopa mhinduro yakakosha yekuvandudza dhizaini uye maitiro ekuunganidza.

Aya angori mamwe eakajairwa PCB prototyping ungano matekiniki anoshandiswa nemakambani akaita seCapel. Iko kuenderera mberi kwekuvandudza tekinoroji kunobvumira vagadziri kuti vaongorore nzira nyowani uye vagadzirise mumunda wedunhu bhodhi musangano.

Capel ruzivo rwakakura uye hunyanzvi hwehunyanzvi muindasitiri yebhodhi redunhu, pamwe neiyo yepamusoro PCB prototype musangano tekinoroji, inoita kuti ive shamwari yakavimbika kune vatengi vayo.Kuzvipira kwekambani kupa inoshanda, yemhando yepamusoro uye ine hupfumi prototype yedunhu bhodhi kugadzira uye masevhisi egungano inoisa parutivi pamusika.

Muchidimbu, kunzwisisa zvakajairika PCB prototyping ungano matekiniki kwakakosha kune vese vagadziri uye vatengi.Makambani akaita seCapel anokwidziridza hunyanzvi hwavo, ruzivo, uye tekinoroji yepamusoro kupa yepamusoro yedunhu bhodhi kugadzira uye magungano mhinduro. Nekusarudza shamwari yakavimbika seCapel, vatengi vanobatsirwa nemaitiro anoshanda, hukuru hwekutonga kwemhando uye zvinodhura mhinduro.

Nguva yekutumira: Oct-19-2023

Back