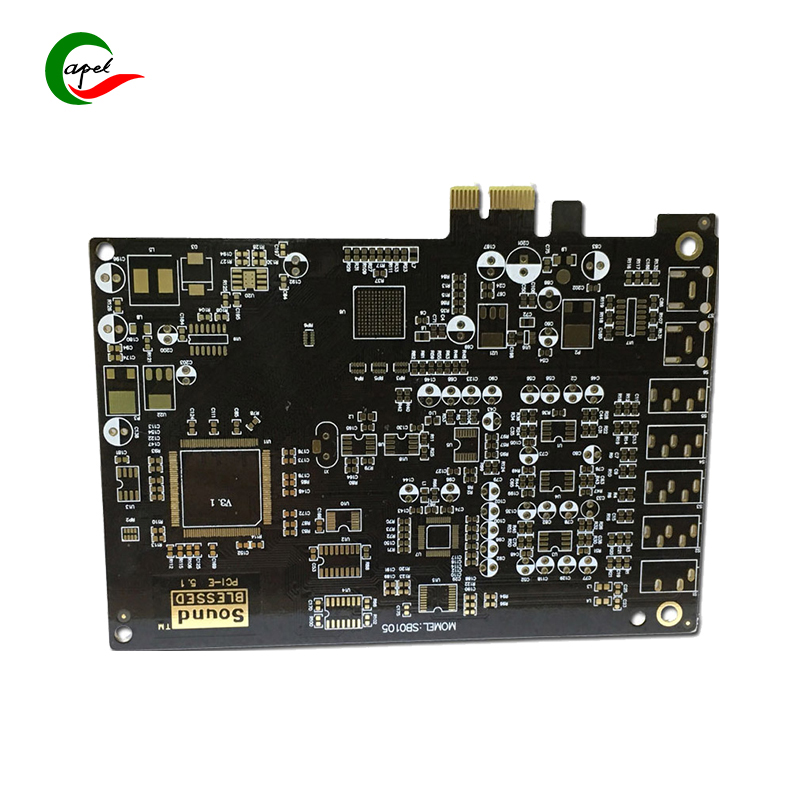

6 Layer PCB Circuit Boards Rapid Pcb Prototyping Pcb Manufacturer China

PCB Process Kugona

| Aihwa. | Project | Technical zviratidzo |

| 1 | Layer | 1-60 (mutsetse) |

| 2 | Maximum processing area | 545 x 622 mm |

| 3 | Minimumboard thickness | 4(layer)0.40mm |

| 6(layer) 0.60mm | ||

| 8(mutsetse) 0.8mm | ||

| 10(layer)1.0mm | ||

| 4 | Minimum line width | 0.0762mm |

| 5 | Minimum spacing | 0.0762mm |

| 6 | Minimum mechanical aperture | 0.15mm |

| 7 | Gomba rusvingo rwemhangura ukobvu | 0.015mm |

| 8 | Metallized aperture tolerance | ± 0.05mm |

| 9 | Non-metallized aperture kushivirira | ± 0.025mm |

| 10 | Gomba kushivirira | ± 0.05mm |

| 11 | Dimensional kushivirira | ± 0.076mm |

| 12 | Minimum solder zambuko | 0.08mm |

| 13 | Insulation resistance | 1E+12Ω (yakajairika) |

| 14 | Plate ukobvu ratio | 1:10 |

| 15 | Thermal shock | 288 ℃ (4 nguva mumasekonzi gumi) |

| 16 | Yakakanganiswa uye yakakotama | ≤0.7% |

| 17 | Anti-magetsi simba | >1.3KV/mm |

| 18 | Anti-kubvisa simba | 1.4N/mm |

| 19 | Solder ramba kuoma | ≥6H |

| 20 | Flame retadancy | 94V-0 |

| 21 | Impedance control | ±5% |

Isu tinoita PCB wedunhu mabhodhi prototype ane makore gumi nemashanu ruzivo nehunyanzvi hwedu

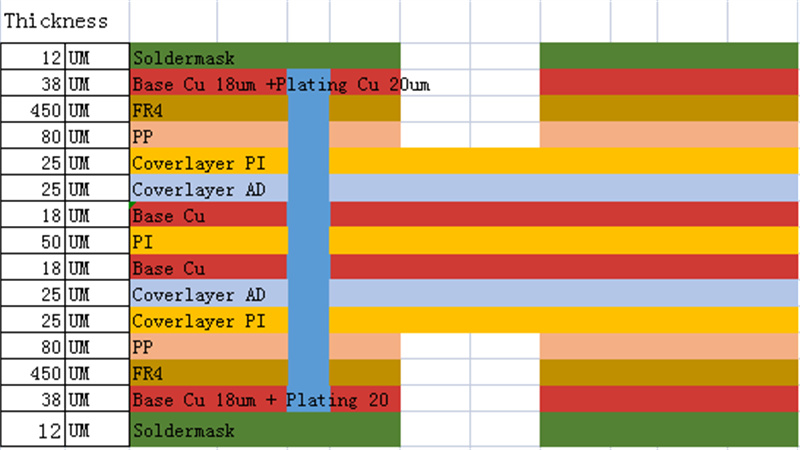

4 layer Flex-Rigid Boards

8 layer Rigid-Flex PCBs

8 layer HDI PCBs

Kuedza uye Kuongorora Equipment

Microscope Testing

Kuongorora kweAOI

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Yedu PCB wedunhu mabhodhi prototype Service

.Ipa rubatsiro rwehunyanzvi Pre-kutengesa uye mushure-kutengesa;

.Tsika anosvika makumi mana akaturikidzana, 1-2days Kurumidza kutendeuka yakavimbika prototyping, Component procurement, SMT Assembly;

.Inobata kune ese ari maviri Medical Device, Industrial Control, Automotive, Aviation, Security, IOT, UAV, Communications etc..

.Zvikwata zvedu zvemainjiniya nevatsvaguri vakazvipira kuzadzisa zvaunoda nehungwaru uye nehunyanzvi.

Nzira yekusarudza mugadziri ane ruzivo uye akasimba kuti aratidze 6-layer redunhu mabhodhi.

1. Tarisa kune izwi-re-muromo uye kuongorora: nzwisisa kuongororwa kwevamwe vatengi uye neshoko-remuromo nezvemugadziri.

Ruzivo rwakakodzera runogona kuwanikwa nekutsvaga online forum, social media kana mapuratifomu ehunyanzvi ekuongorora uye mhinduro.Tarisa kune avo vane mukurumbira wakasimba uye makore echiitiko.

2. Chiitiko uye unyanzvi: Iva nechokwadi chokuti mugadziri ane ruzivo rwakapfuma uye unyanzvi mukugadzira 6-layer circuit board.

Dzidza nezvenhoroondo yavo nekwavanobva, kusanganisira kuti vanga vagara kwenguva yakareba sei muindasitiri uye huwandu hwemapurojekiti avakapedza.

3. Unyanzvi hwekugona uye zvishandiso: Tarisa kana mugadziri ane zvigadzirwa zvepamberi uye tekinoroji yekugadzira 6-layer redunhu mabhodhi.

Dzidza nezve kugona kwavo kugadzira mabhodhi akaomarara uye akakwira-density magungano kuti ave nechokwadi chekuti vanogona kuzadzisa zvaunoda.

4. Kudzora kwehutano: Nzwisisa maitiro ekugadzirisa maitiro emugadziri uye maitiro.Ivo vane yakasimba yemhando yekudzora zviyero uye yakakodzera midziyo yekuyedza kuti ive nechokwadi chemhando yechigadzirwa, senge kuita ISO 9001 mhando yekutonga system.

5. Kuvimbika uye kuburitsa: Ongorora kuvimbika kwemupi uye kuendesa.Vanokwanisa here kupedzisa mapurojekiti nenguva uye kupa nguva dzekutumira dzakaringana.Bvunza kana vaine chirongwa chekuchengetedza chekukurumidza kana kunonoka kana zviitiko zvisingatarisirwi.

6. Taura nevatengi varipo: Kana zvichibvira, taura nevatengi varipo vemutengesi.Dzidza nezve ruzivo rwavo rwekushandira pamwe uye kugutsikana, pamwe nemaitiro ekushanda emugadziri uye kumhanya kwekupindura.

7. Bvunzurudza kana kutaurirana nevagadziri: ita mabvunzurudzo kana kutaurirana nevanogona kugadzira, uye vabvunze nezve proofing zvinodiwa uye tekinoroji zvinodiwa.Tarisa uone kana mhinduro dzavo uye tsananguro dzavo dzakarurama, dzeunyanzvi, uye dzinogutsa, kuti ugotonga kana vane ruzivo nesimba raunoda.

8. Mutengo uye sevhisi: Pakupedzisira, funga mutengo uye mushure mekutengesa sevhisi zvizere.Ita shuwa kuti mutengo unonzwisisika uye unopa kwakakodzera mushure mekutengesa-rutsigiro, senge tekinoroji kubvunza, kutevedza kugadzira uye kugadzirisa matambudziko, nezvimwe.

Iyo proofing process ye6 layer PCB wedunhu mabhodhi

1. Gadzira dhiyabhorosi dhizaini uye dhizaini: kutanga gadzira dhizaini dhizaini dhizaini uye marongero zvinoenderana nedunhu dhizaini zvinodiwa.Iri inhanho yakakosha pakuona hukuru hwebhodhi, mitemo yenzira, kuiswa kwechishandiso, nezvimwe.

2. Ita mafaira ebhodhi redunhu: Shandisa PCB dhizaini software kuti uchinje redunhu schematics uye marongero kuita redunhu bhodhi mafaera.

Aya mafaira anowanzo sanganisira mafaira eGerber, drill mafaira, soldermask mafaira, nezvimwe.

3. Simbisa dhizaini: Pamberi pebhodhi redunhu rinogadzirwa, dhizaini yedunhu inosimbiswa.Ita shuwa kuti dhizaini yako yebhodhi haina zvikanganiso uye manufacturability nyaya nekuita dunhu simulation uye DFM (Design for Manufacturability) ongororo.

4. Tumira kurongeka: Tumira magwaro ebhodhi uye zvinoenderana nezvinodiwa zvekugadzira kumugadziri webhodhi.Zvinowanzodikanwa kupa faira fomati, redunhu bhodhi zvinhu, nhamba yematanho, padhi zvinodiwa, solder mask color, silk screen zvinodiwa, process zvinodiwa, nezvimwe.

5. Gadzira bhodhi redunhu: Mugadziri webhodhi wedunhu anogadzira zvinoenderana nemagwaro akapihwa.

Izvi zvinosanganisira kushandisa mafirimu matete kugadzira akadhindwa edunhu bhodhi mapatani, kemikari etching kana machining kuti abvise zvisingadiwe mhangura akaturikidzana, drilling, copper plating, overlays (pads, soldermask, silkscreen), dicing uye mamwe maitiro.

6. Ita bvunzo inoshanda: Ita bvunzo inoshanda pabhodhi rakagadzirwa kuti ive nechokwadi chekushanda kwayo.

7. Unganidza bhodhi redunhu: isa bhodhi redunhu mumidziyo inoenderana yebvunzo inoshanda kana inoshanda application.

8. Ongorora mhedzisiro yekuongorora: Mushure mekugamuchira proofing redunhu bhodhi, ita ongororo yakazara.

Tarisa uone kana kutaridzika uye saizi yebhodhi redunhu zvinoenderana nezvinodiwa, tarisa padhi uye welding mhando, uye ongorora kana kuita uye kushanda kwebhodhi redunhu zvakajairika.

9. Kugadziridza uye optimization: Ita shanduko inodiwa uye optimization zvinoenderana nemhedzisiro yekuongorora.

Kana bhodhi redunhu rinowanikwa rine matambudziko kana kuti rinoda kuvandudzwa, mafaira ekugadzira anogona kuchinjwa maererano.

10. Kudzokororazve: Kana bhodhi redunhu rine huwandu hukuru hwekugadzirisa kana kuti dzakawanda dzinodiwa, kudzokorora kunogona kuitwa.

Dzokorora maitiro apfuura, tumira faira kufekitori kuti igadzirwe zvakare, uye ongorora uye dzokorora zvakare.

11. Kugadzirwa kwemasa: Kana magadzirirwo uye kushanda kwebhodhi redunhu zvinogutsa, kugadzirwa kwemazhinji kunogona kuitwa.Vagadziri vanogadzira zvinoenderana nemafaira ekupedzisira ekugadzira, uye vanogadzira akawanda mabhodhi edunhu kupa kune vatengi.

12. Rondedzera uye gadzirisa cheni yekugovera: Zvinonyanya kukosha kuteedzera nekugadzirisa cheni yekugovera mukati meiyo proofing uye misa yekugadzira maitiro.

Vimbiso yekupihwa kwezvinhu, gadziridza nenguva kufambira mberi kwekugadzira, hurongwa hwezvinhu, nezvimwewo, uye ive nechokwadi chekuuya-nguva kwemabhodhi edunhu.